Pultrusion method of making composite friction units

a friction unit and composite technology, applied in the field of composite friction elements, can solve the problems of releasing potentially harmful amounts of it into the environment, affecting the composition and the manufacturing method is not satisfactory, so as to improve the composition and manufacturing method of the brake friction lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

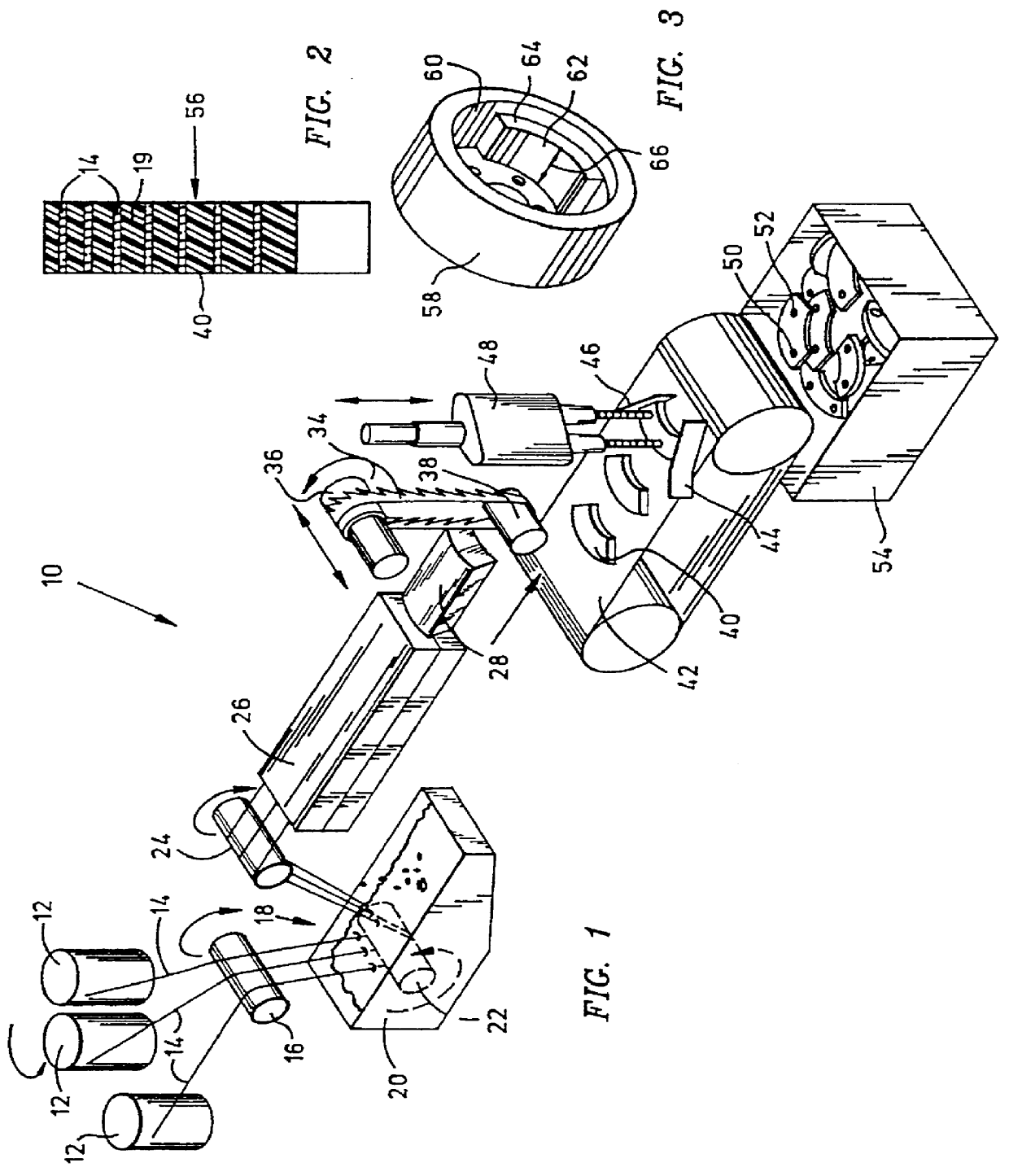

Referring to FIG. 1 of the drawing, there is schematically illustrated the simplest form of an exemplary system for carrying out a the process of the invention for making brake friction units in accordance with the invention. The system, designated generally by the numeral 10, comprises a plurality of creels 12 from which a plurality of strands 14 of an elongated continuous fiber or arrays of fiber are drawn and passed through suitable guide means across suitable guide rollers or bars 16 to and through an impregnating or wetting bath 18 of a suitable resin such as a phenolic resin. The fibers may be in the form of individual strands, woven fabrics, matting, or stitched fabrics of combinations of them.

The fibers or strands 16 are the primary fibers and are coated or wetted by a resin in any suitable manner. In the illustrated embodiment they pass into or through a bath of a suitable liquid resin contained within a reservoir 20 for wetting or impregnating the fibers or strands. They c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap