Resilient edges for power operated doors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

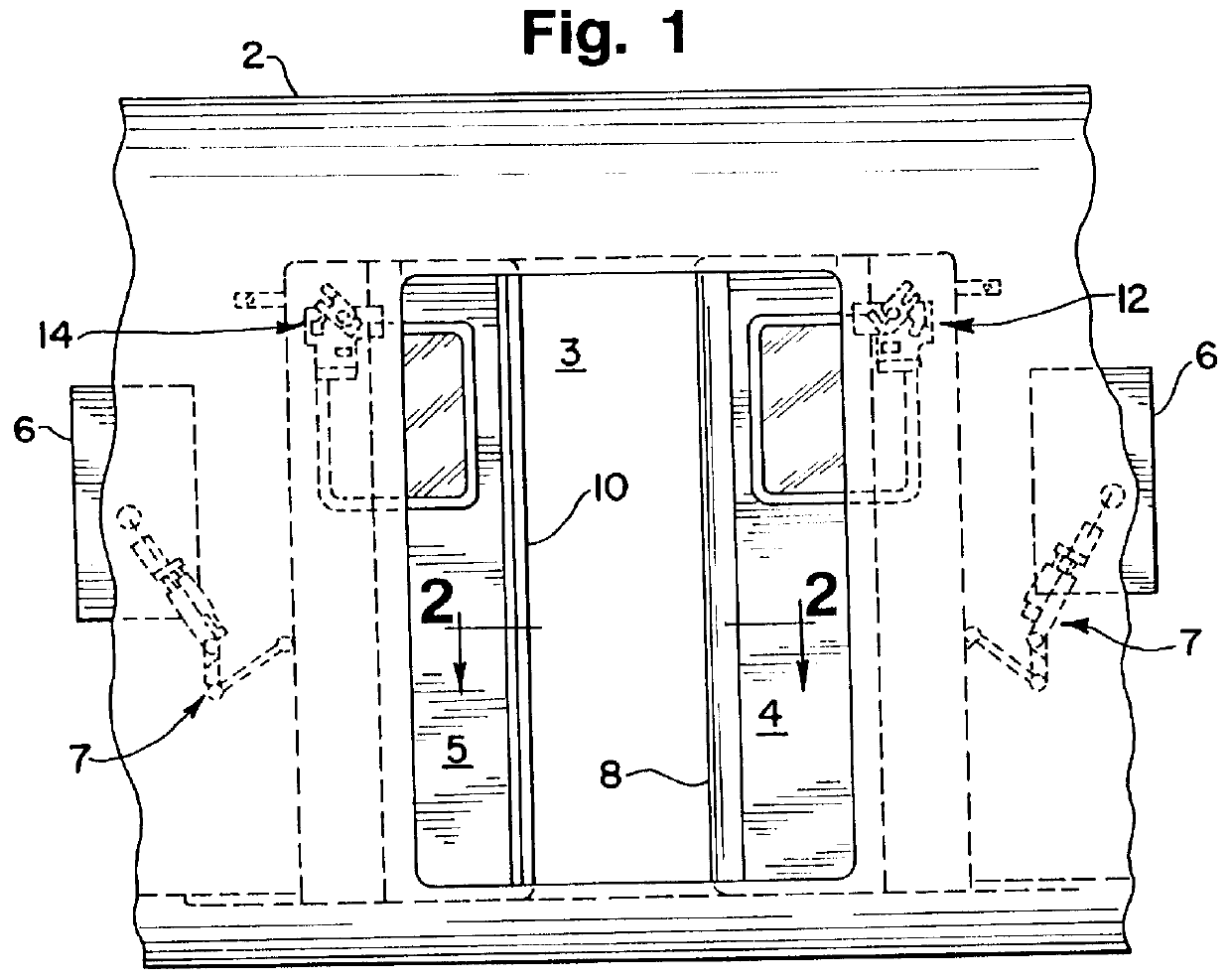

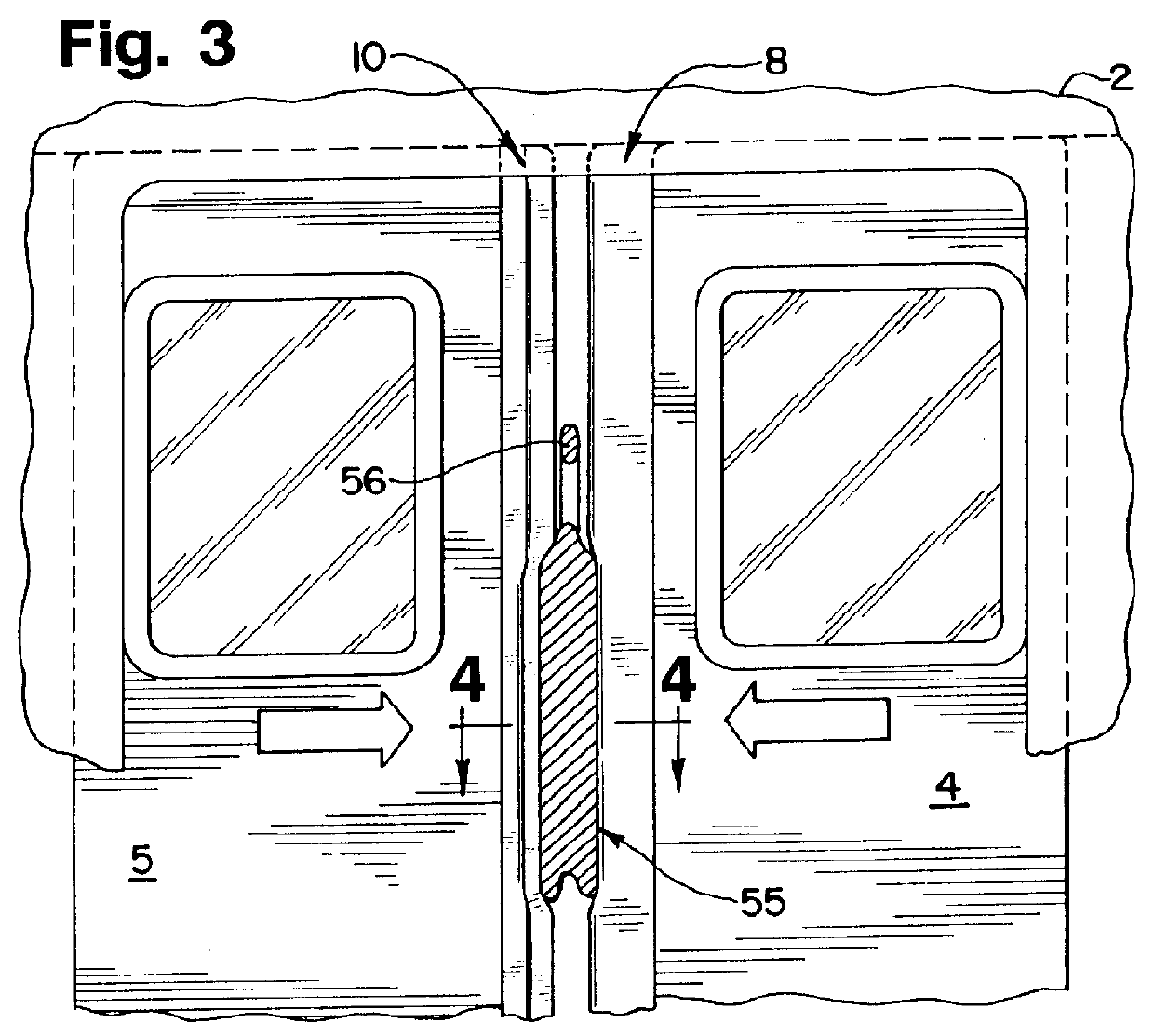

With particular reference to FIG. 1, there is shown a partial representation of a car body 2 showing bi-parting door leaves 4 and 5 driven by power operators 6 to open and closed position over an opening 3 in the side wall of car body 2. Also shown are door obstruction sensing and free-wheeling panel detection switch assemblies 12 and 14 (not a part of the invention, but disclosed in more detail in above-mentioned U.S. Pat. No. 5,280,754. Door panels 4 and 5 are mounted in car body 2 by saltable hanger means (not shown) and are moved from opened to closed over the opening 3 through drive arm assemblies 7. The internal or mating edges of door panels 4 and 5 constituting the door / passenger interface, have edges 8 and 10, respectively, attached thereto.

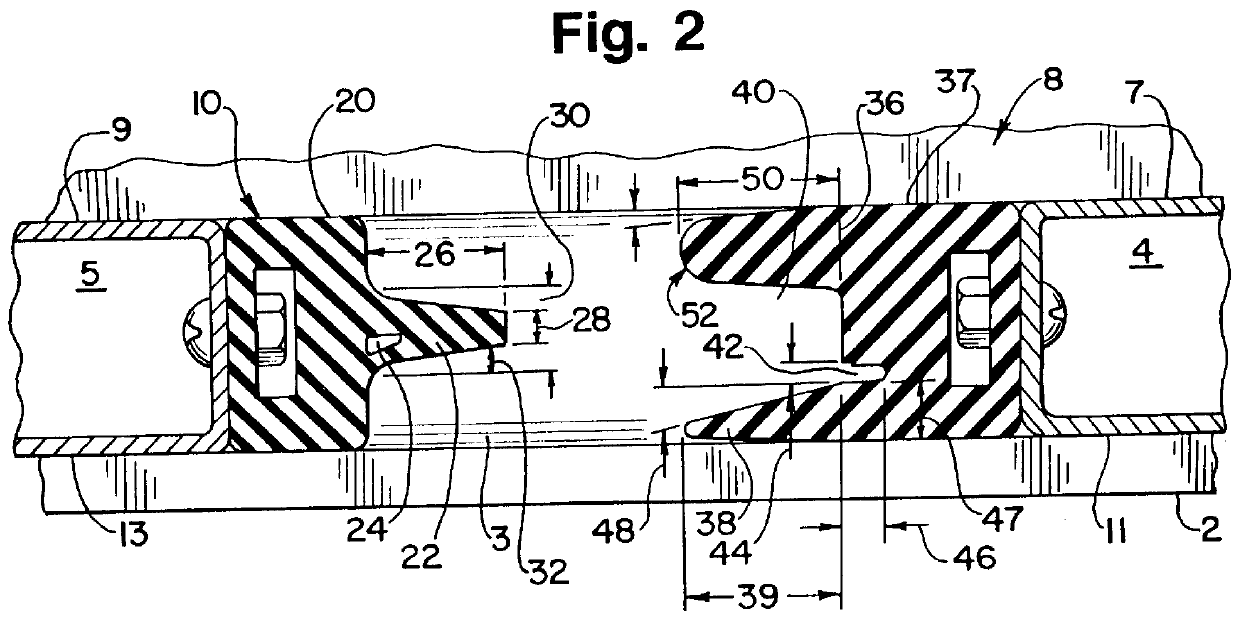

Turning now to FIG. 2, there is shown in partial cross-section passenger interface edges 8 and 10 attached to door panels 4 and 5, respectively. As shown, panel surfaces 7 and 9 face the inside of car body 2, whereas, surfaces 11 and 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com