Water treatment cartridge and base

a technology of water treatment cartridge and water treatment base, which is applied in the direction of filtration separation, multi-stage water/sewage treatment, separation process, etc., can solve the problems of difficult opening, long and ungainly filter element change, and difficult opening of filter element change in the conventional domestic filter housing, etc., to achieve convenient removal, maintain efficiency and water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

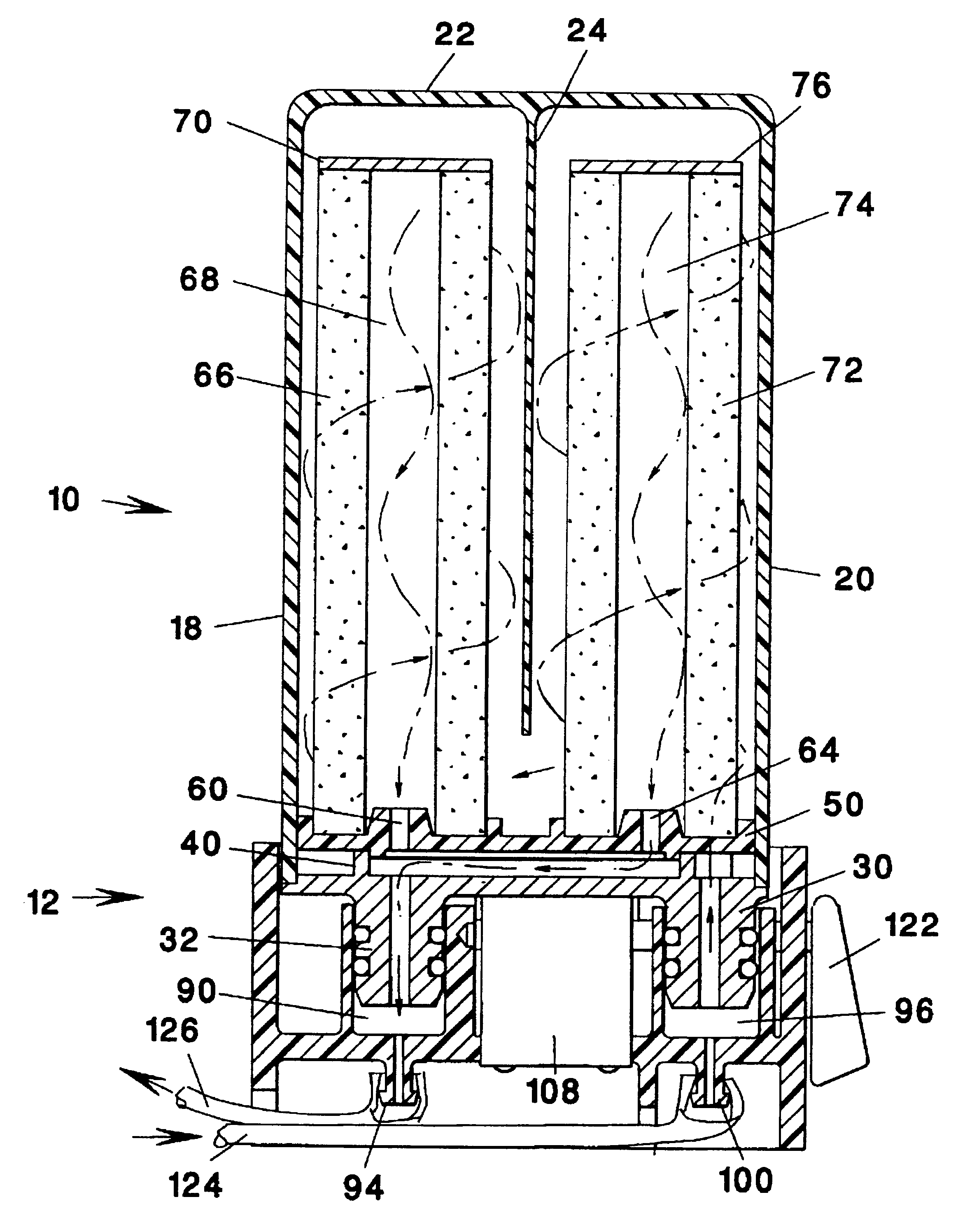

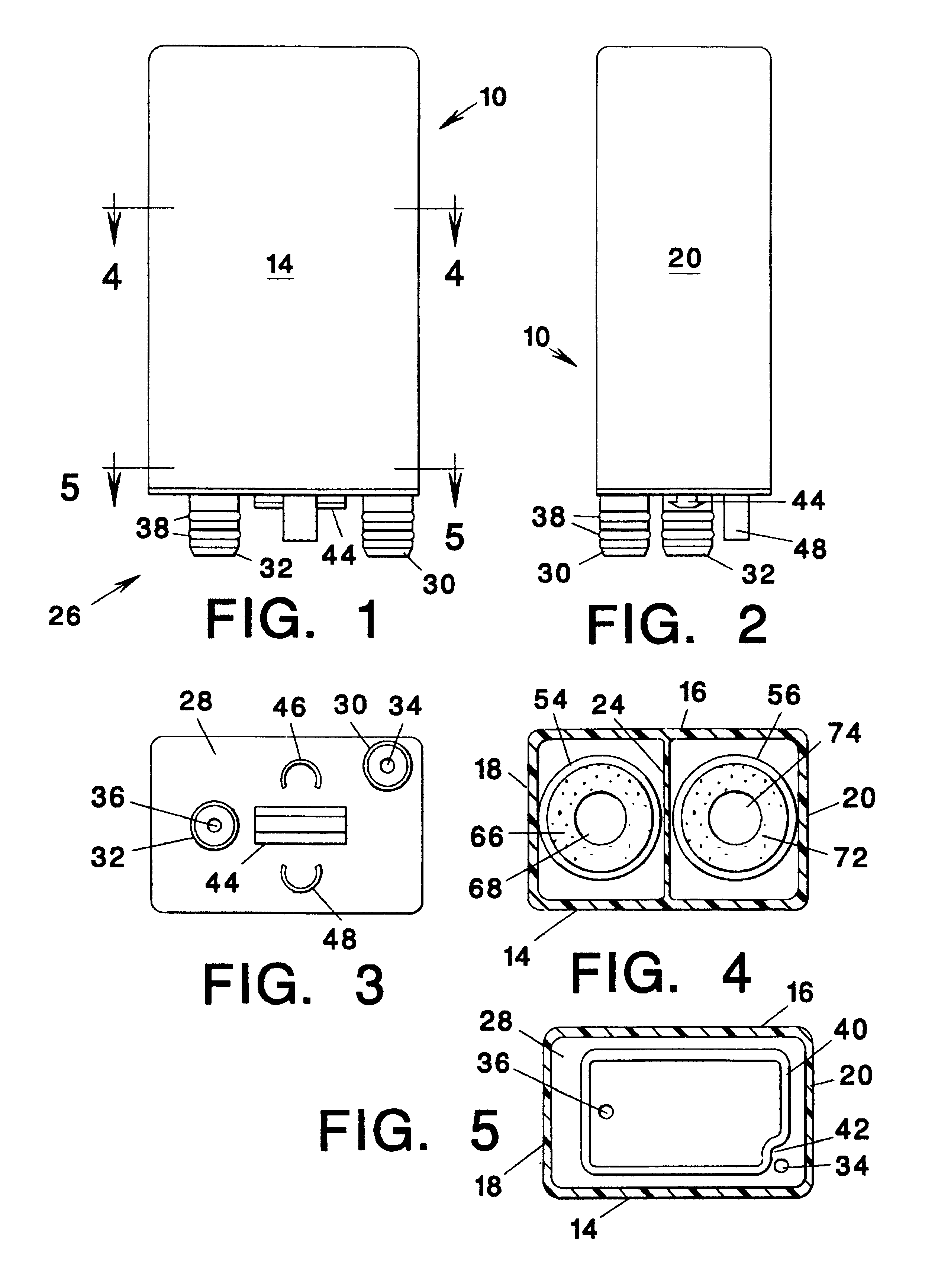

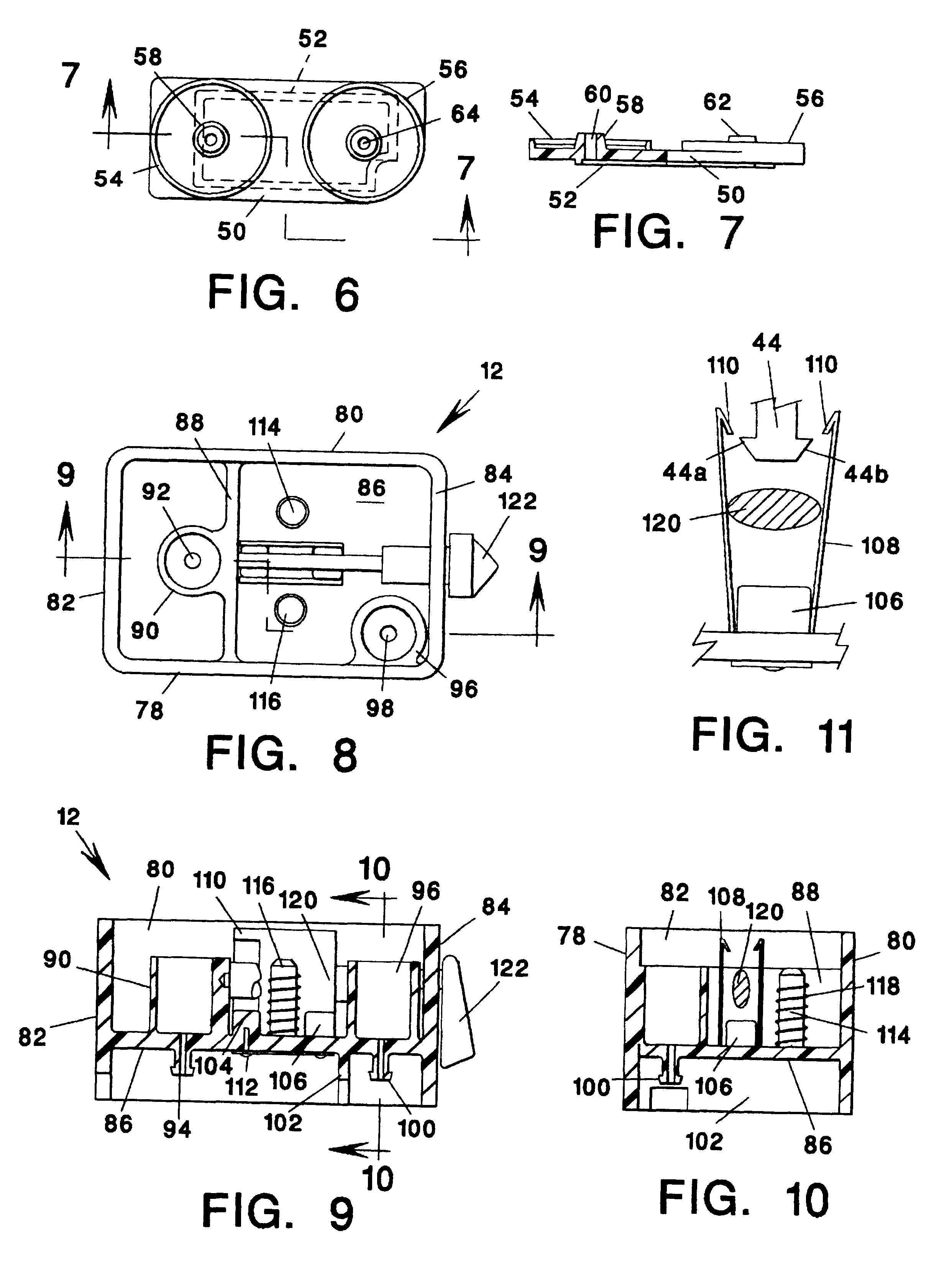

The invention comprises a base member and a filter cartridge which is insertable into the base member. The cartridge is illustrated by FIGS. 1-7 and the base by FIGS. 8-10. Reference may also be had to FIG. 12 which illustrates the cartridge 10 mounted in the base 12.

The cartridge 10 comprises a main housing of substantially rectangular cross-section comprising a front wall 14, a rear wall 16, left 18 and right 20 side walls, and a top wall 22 (FIG. 12). A stiffening web 24 extends downwardly from top wall 22 between front wall 14 and rear wall 16. The stiffening web performs the important function of preventing deformation of the housing when under full line water pressure. This allows for a relatively flat housing, as opposed to the cylindrical housings of the prior art. A cartridge base 26 closes the bottom of the housing. It is in the form of a base plate 28 from which extend a hollow water inlet stud 30 and a similar water outlet stud 32. The studs 30, 32 have axial bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com