Tibial prosthetic implant with offset stem

a tibial prosthetic and offset technology, applied in the field of total knee arthroplasty implants, can solve the problems of substantially offset central stems, inhibiting adequate initial stability and fixation, etc., and achieve the effect of optimal keel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

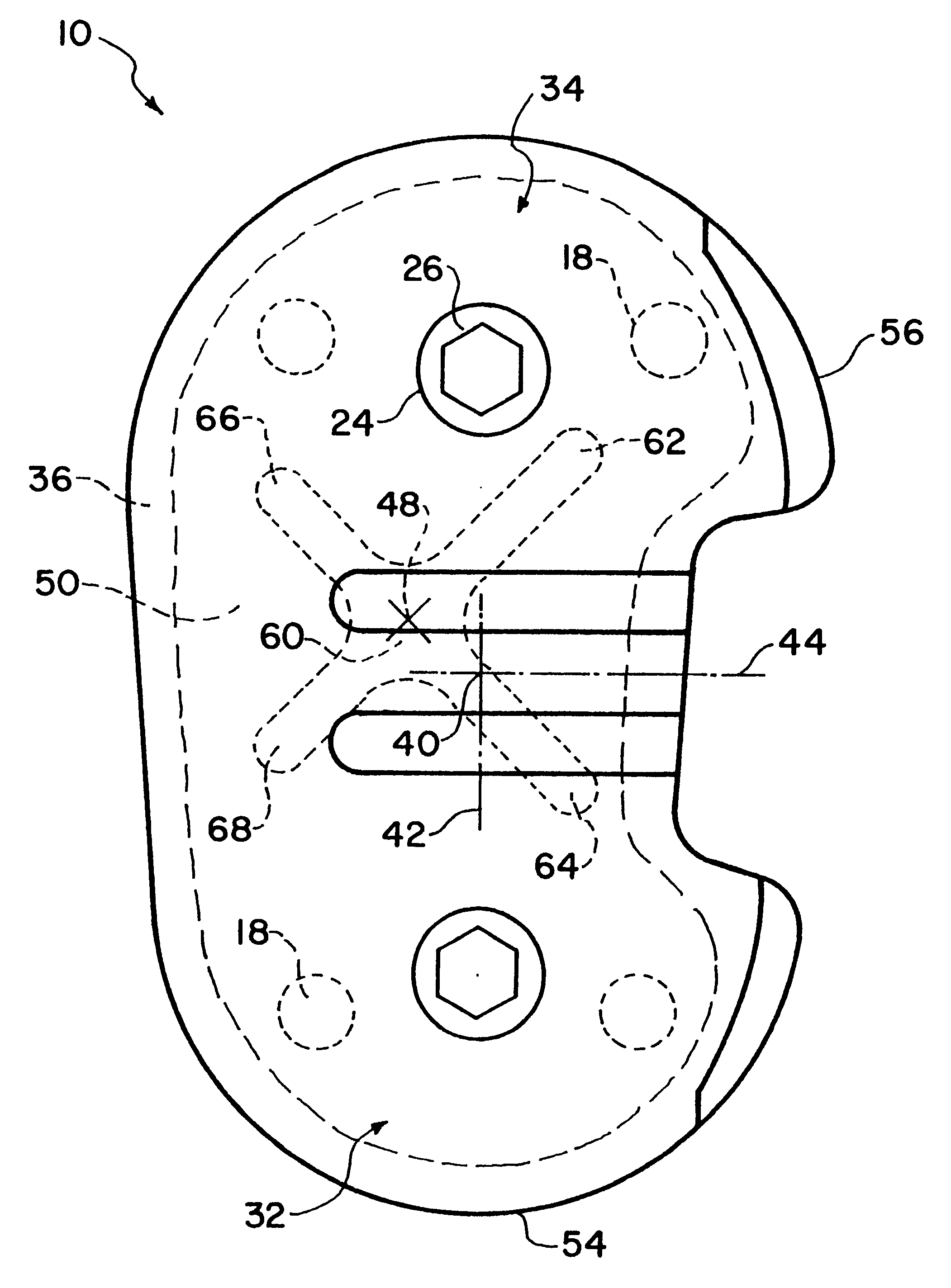

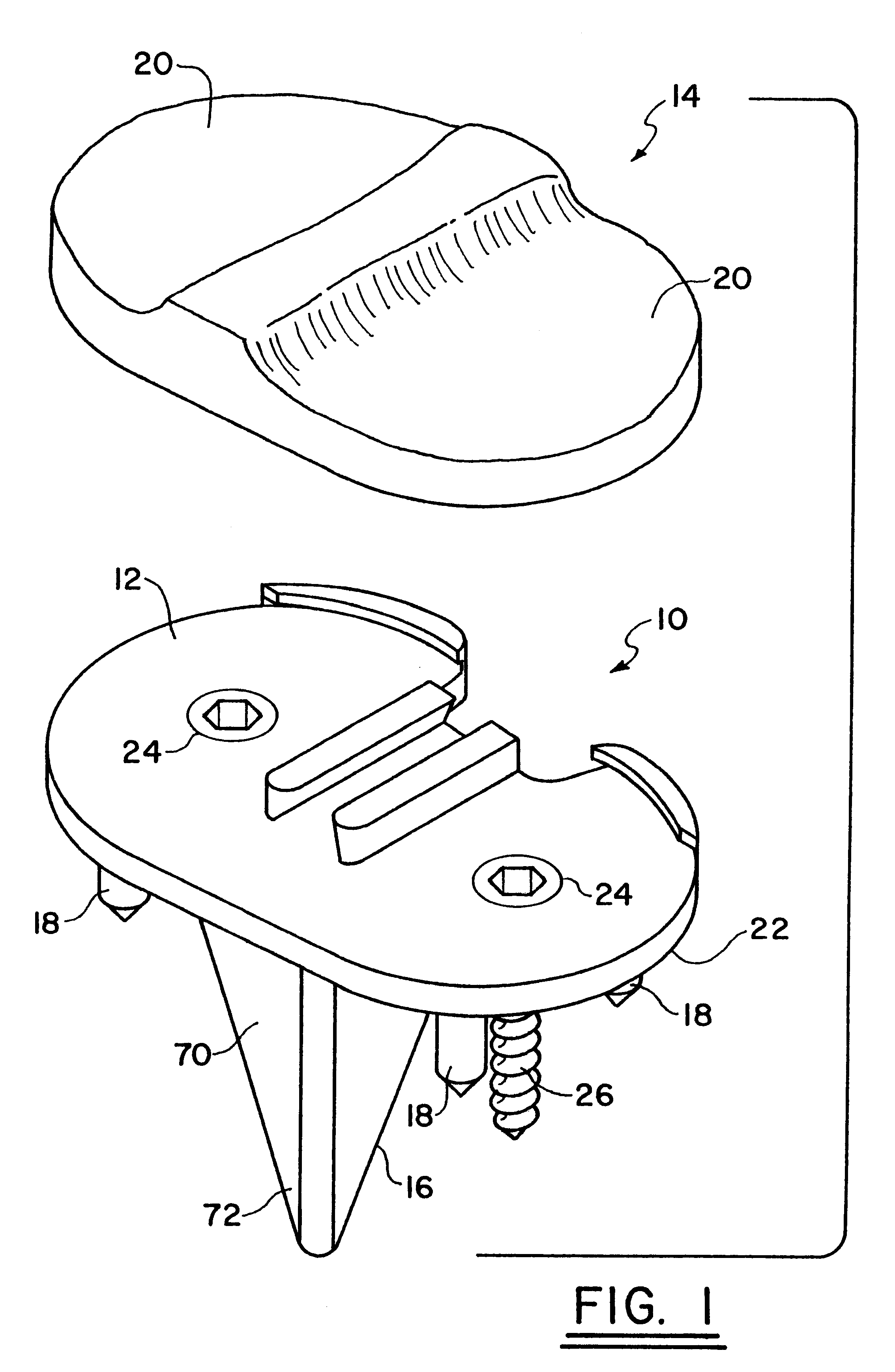

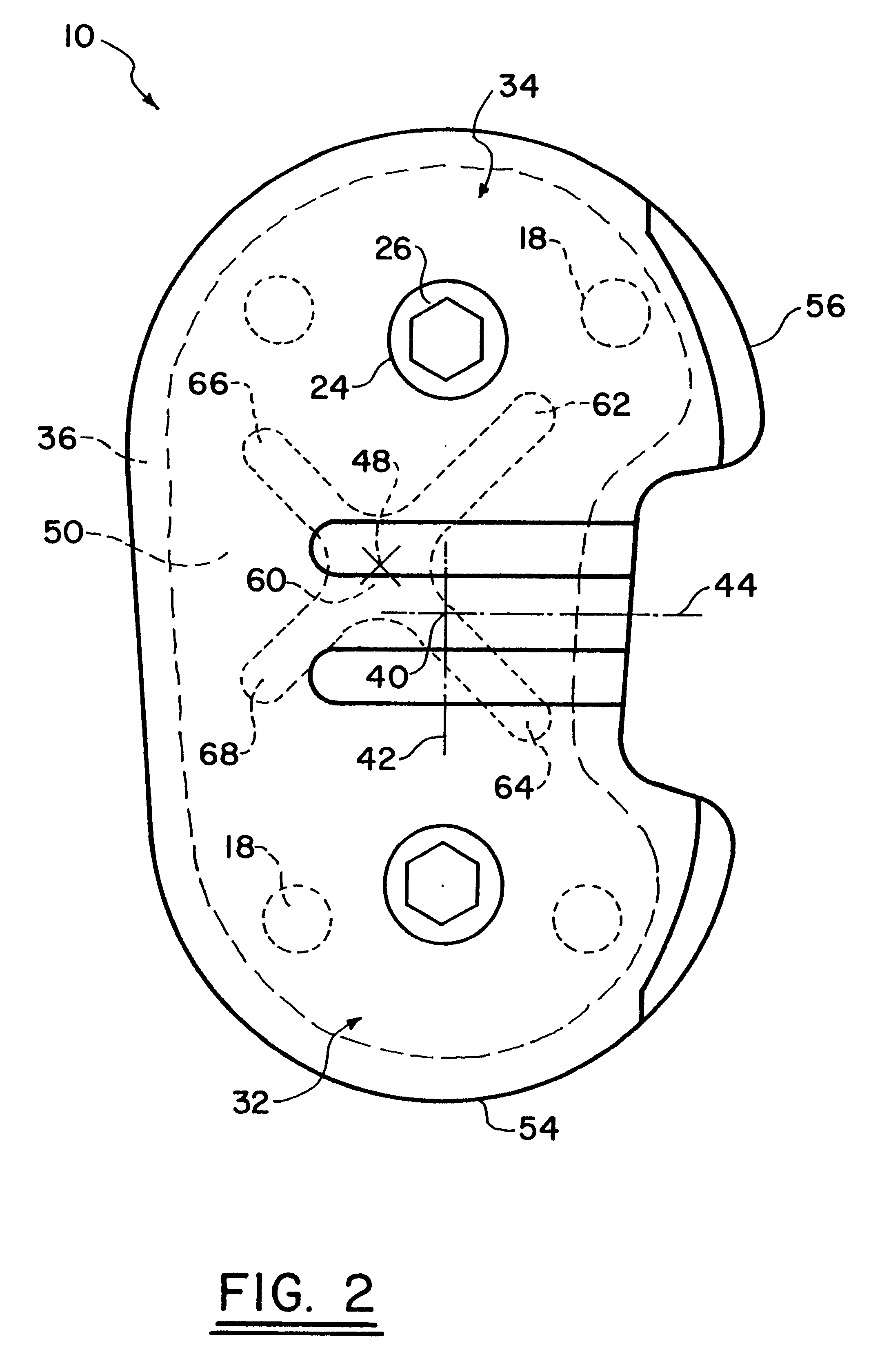

Referring particularly to FIG. 1 a tibial implant 10 embodying the principles of the invention includes a base 12 and an articulating portion 14. A stem 16, and preferably, a plurality of pegs 18 are connected to the base 12 of the implant. As shown in FIGS. 2 and 3, the base 12 also includes two openings 24 for receiving bone screws 26. The bone screws 26 along with the openings 24 form attachment means for attaching the implant 10 to the patient's tibia as described below.

Although the base 12 and articulating portion 14 may be integrally formed, the preferred form of the invention shown in the figures is modular with a base plate forming the base 12 and a separate insert comprising the articulating portion 14. The base plate and insert are adapted to connect together by suitable means to form the implant 10. The articulating portion or insert 14 is preferably formed from a suitable plastic material and includes articulating surfaces 20 adapted to articulate with the femoral condyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com