Panel cutting apparatus

a cutting machine and panel technology, applied in the field of rotary cutting devices, can solve the problems of improper alignment between the cutting die and the envelope blank, improper sealing, and prior art panel cutting machines, and achieve the effects of minimizing the number of magnetic strips, maximizing the number of vacuum orifices, and improving the distribution of magnets and air orifices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

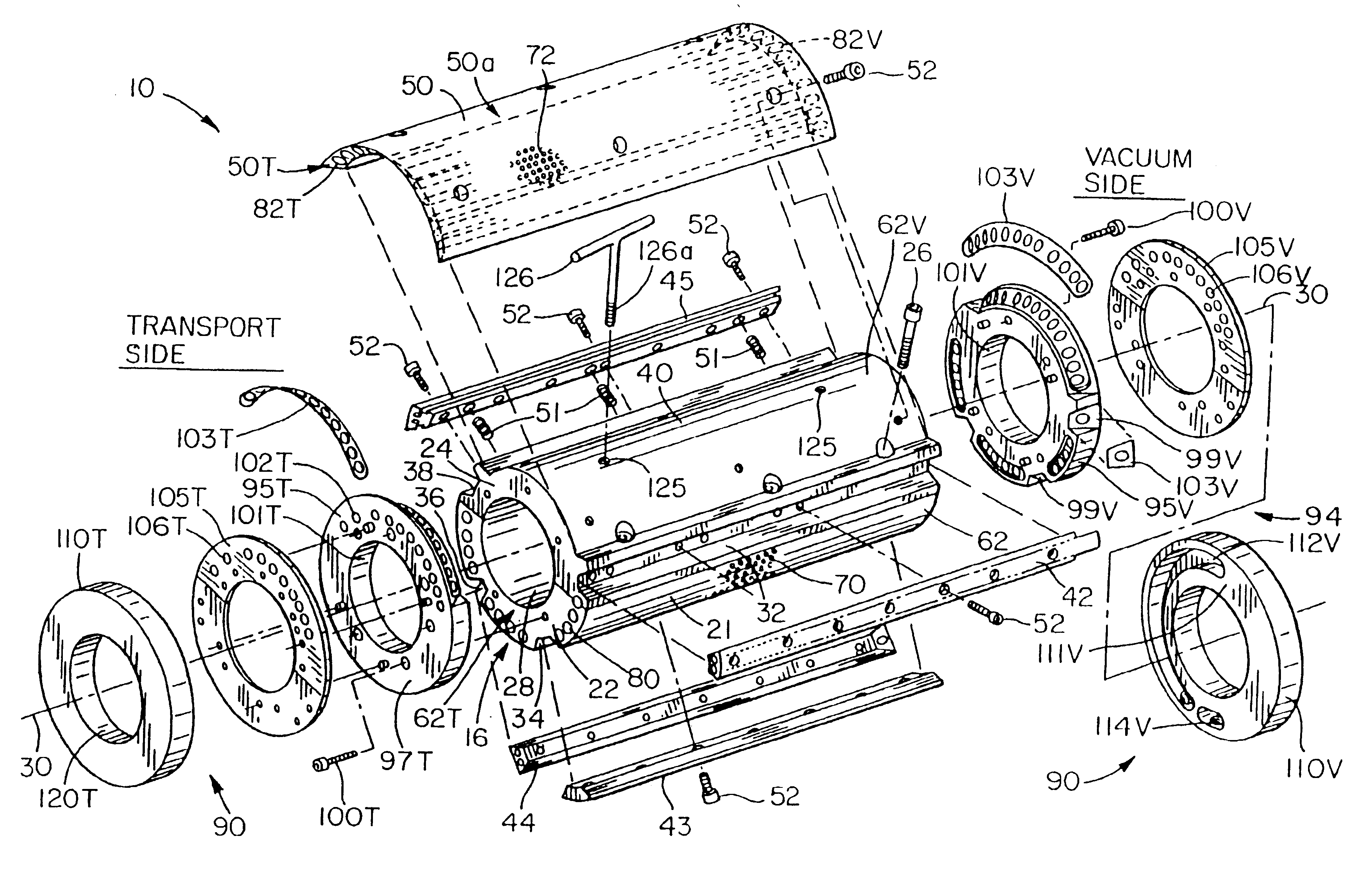

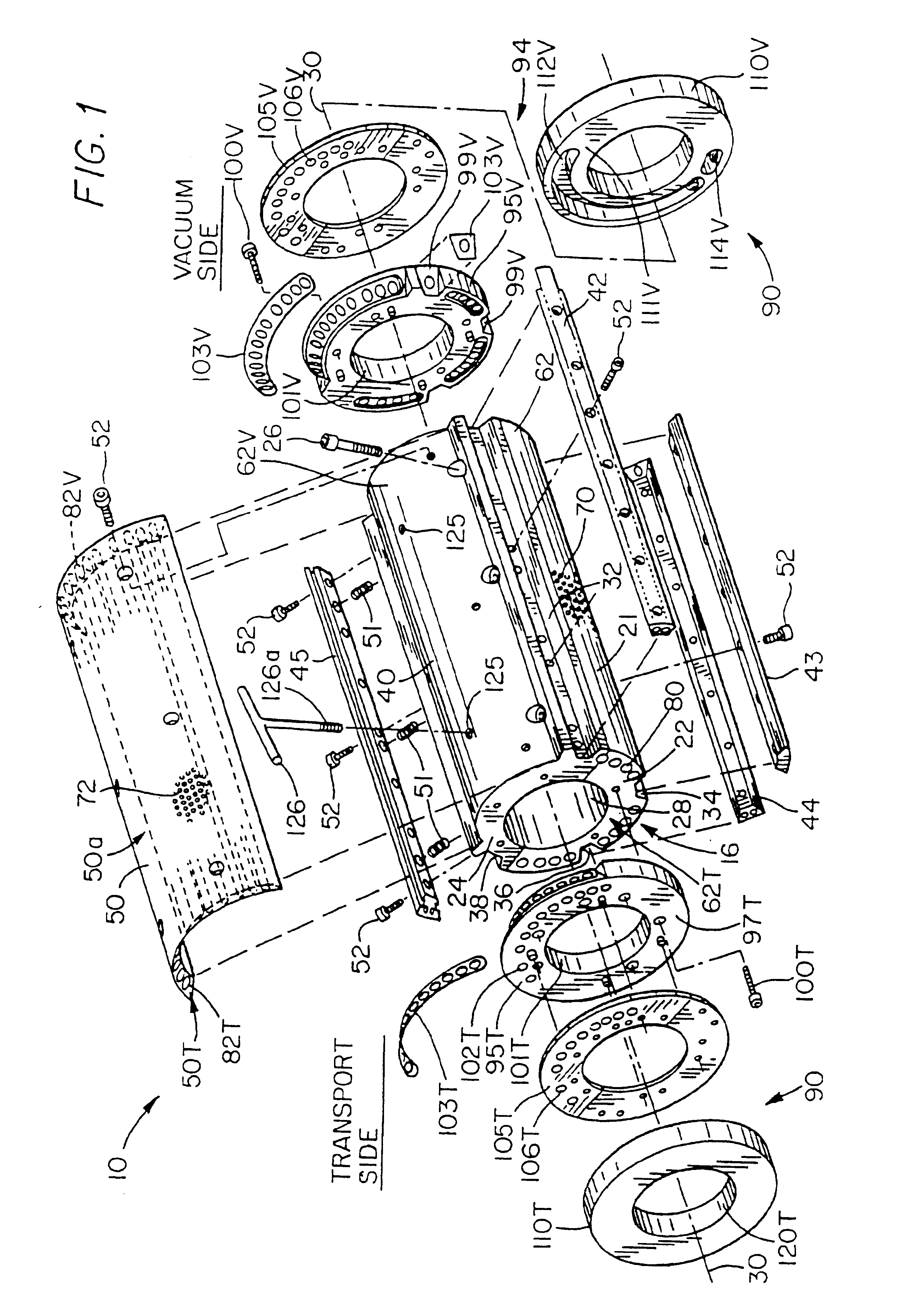

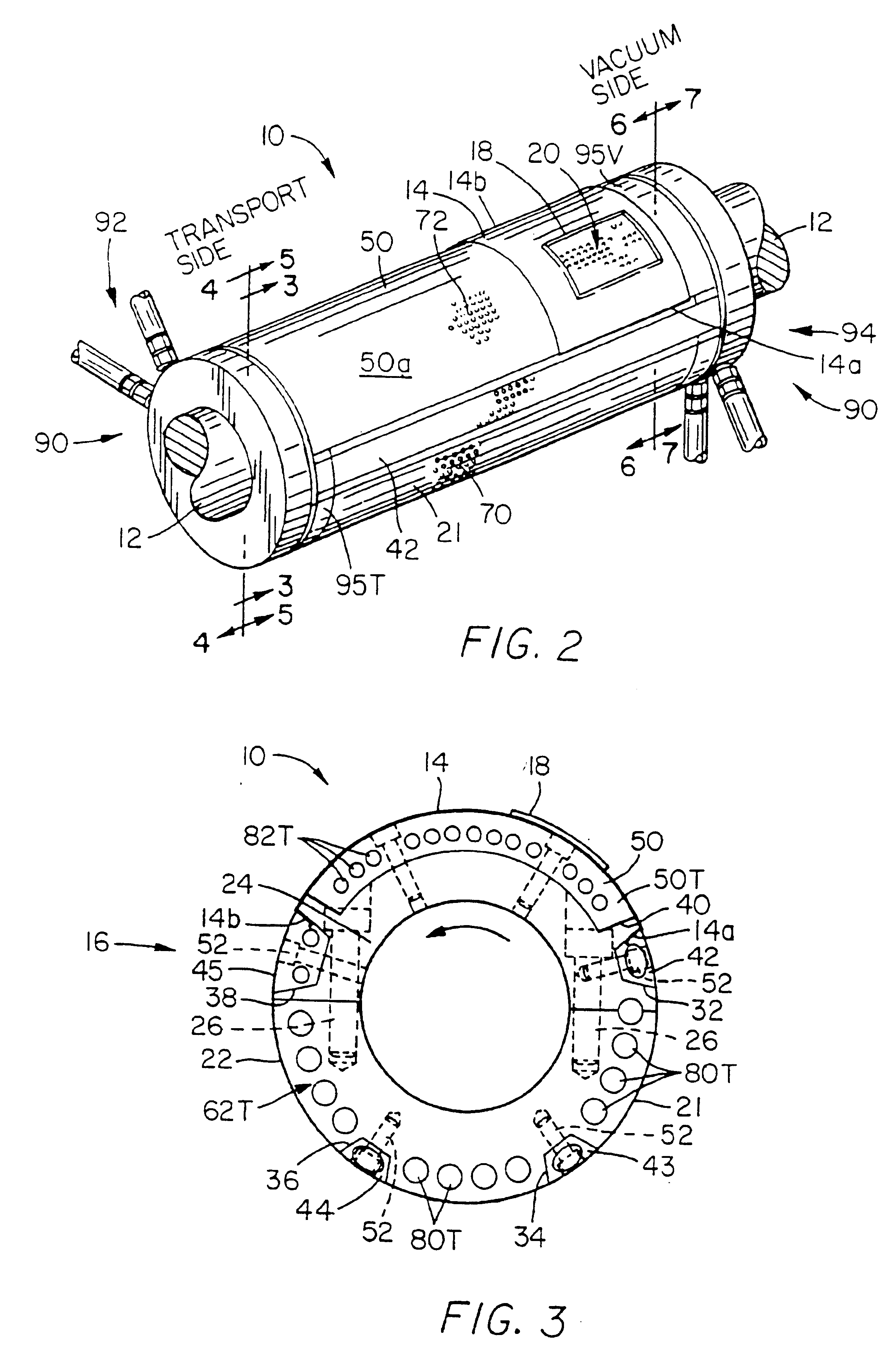

Referring to the drawings and more particularly to FIGS. 1-2, one embodiment of a rotary cutting tool 10 for cutting panels P and the like from sheet-like material such as envelopes and the like is mounted on a drive shaft 12 in accordance with the present invention. The cutting tool 10 comprises a cutting die 14 mounted on a die holder 16. The drive shaft 12 rotates the die holder 16 so that the cutting die 14 engages a different envelope blank B for each rotation of the die holder 16.

The die holder 16 cooperates with an air delivery assembly in order to receive and retain the envelope blank B during the cutting operation. One embodiment of an air delivery assembly in accordance with certain objects of the invention is generally referenced as 90 although conventional air delivery assemblies may also be used. The die holder 16 has a transport side which is generally depicted as the left side in FIGS. 1 and 2 and a vacuum side which is generally depicted as the right side. The transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com