Torque transmitting and torsion damping apparatus for use in motor vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

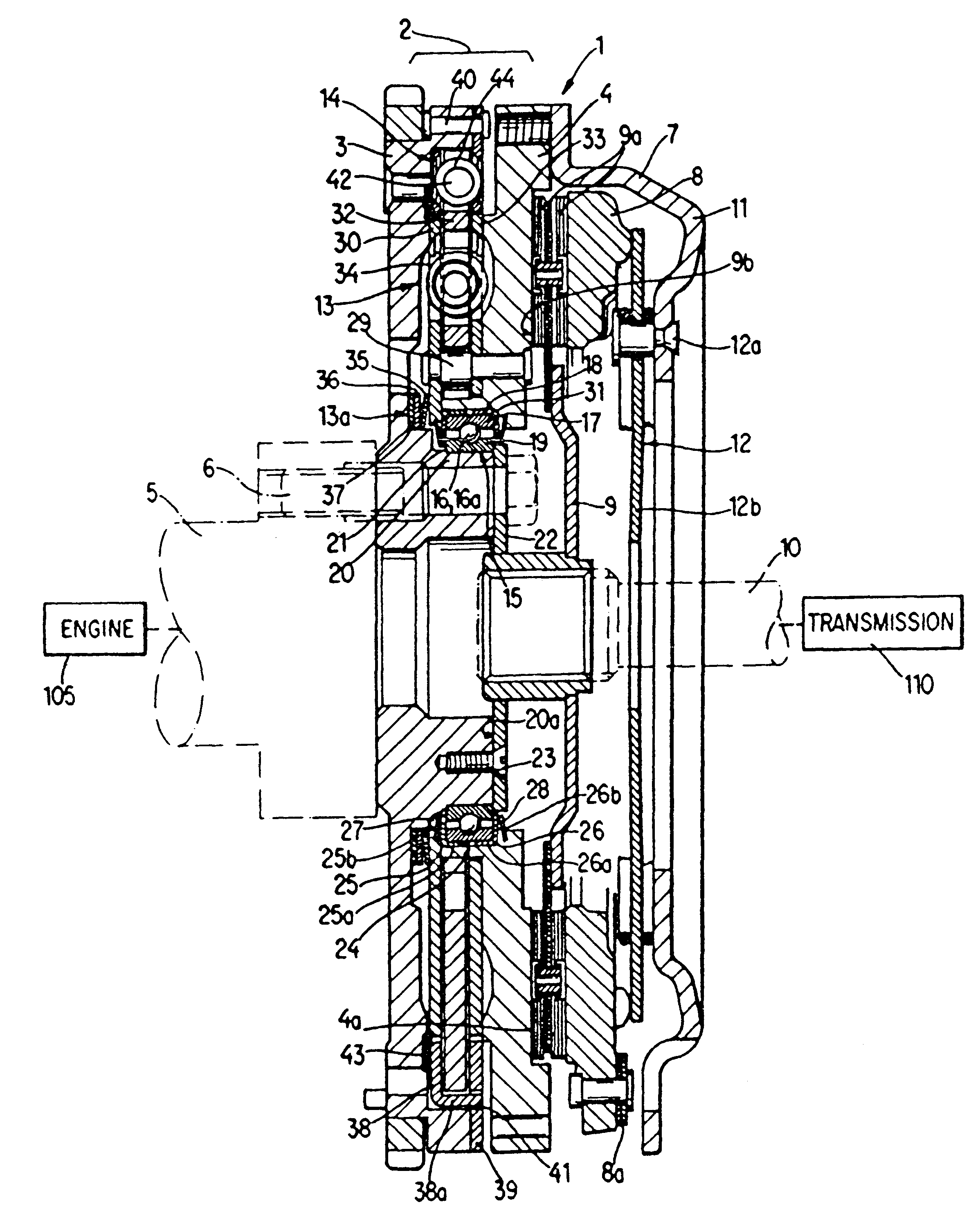

The torsion damping apparatus 1 of FIG. 1 comprises a composite flywheel 2 including a first flywheel 3 receiving torque from an internal combustion engine 105 by way of a crankshaft 5 which is secured thereto by an annulus of bolts 6 or analogous fasteners, and a second flywheel 4 which transmits torque to the input element 10 of a change-speed transmission 110 in a motor vehicle by way of a friction clutch 7. The friction clutch 7 comprises an axially shiftable pressure plate 8, an axially fixed pressure plate which constitutes the second flywheel 4, a clutch plate or disc 9 with two friction linings 9a, a cover or housing 11 and a diaphragm spring 12 which normally urges the pressure plate 8 against the adjacent lining 9a so that the friction- and heat-generating (second) surface 9b of the other lining 9a bears against the adjacent friction- and heat-generating (first) surface 4a of the flywheel 4. The diaphragm spring 12 is tiltably mounted between two wire-like ring-shaped seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com