Termite control

a termite and chemical technology, applied in the direction of insect catchers and killers, power cables, structural elements, etc., can solve the problems of affecting the safety of people applying chemicals and other people in the vicinity, exposing them to the potential danger of chemicals used to control termites, and enduring danger afterward, so as to achieve convenient transportation and application, convenient work, and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

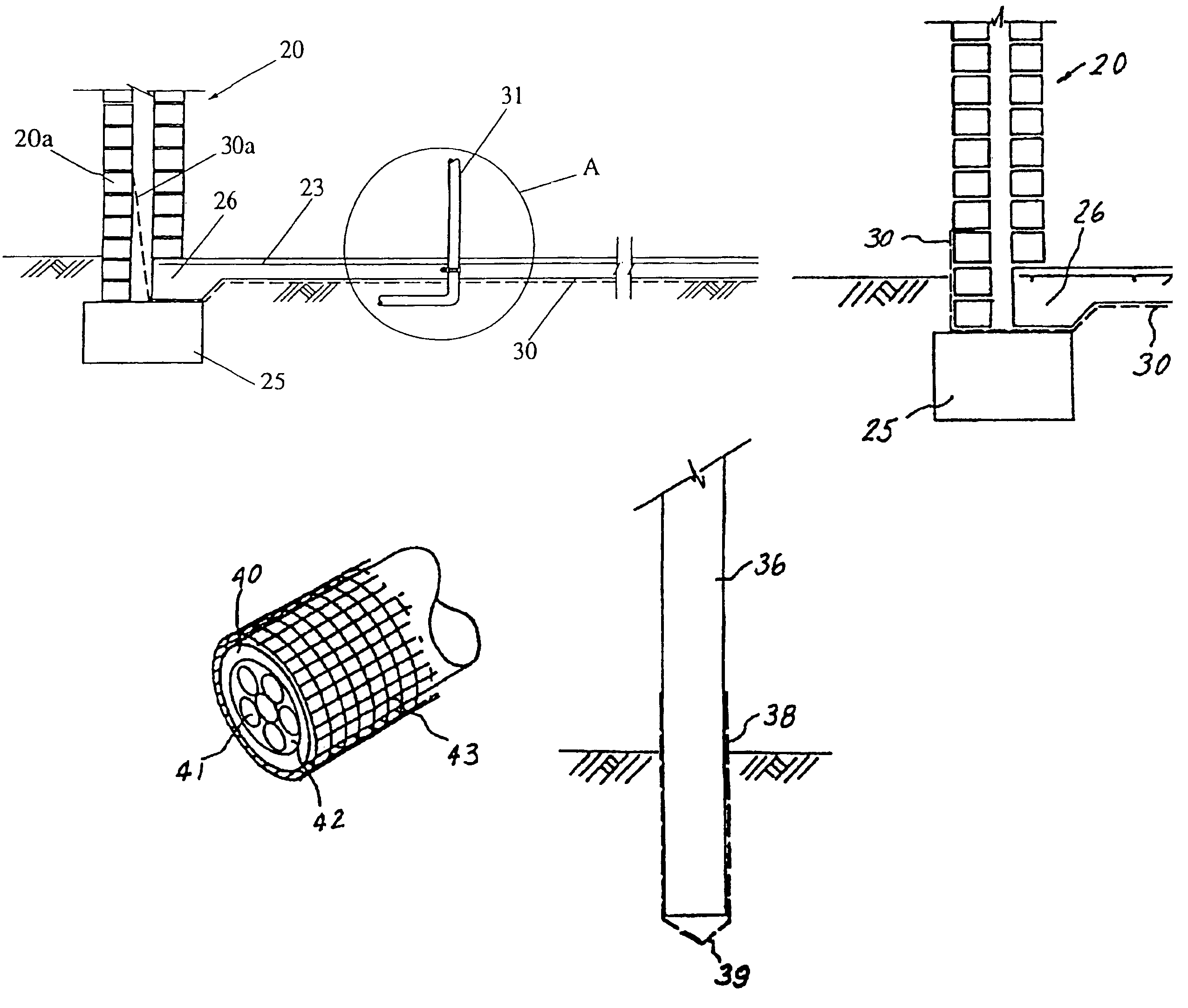

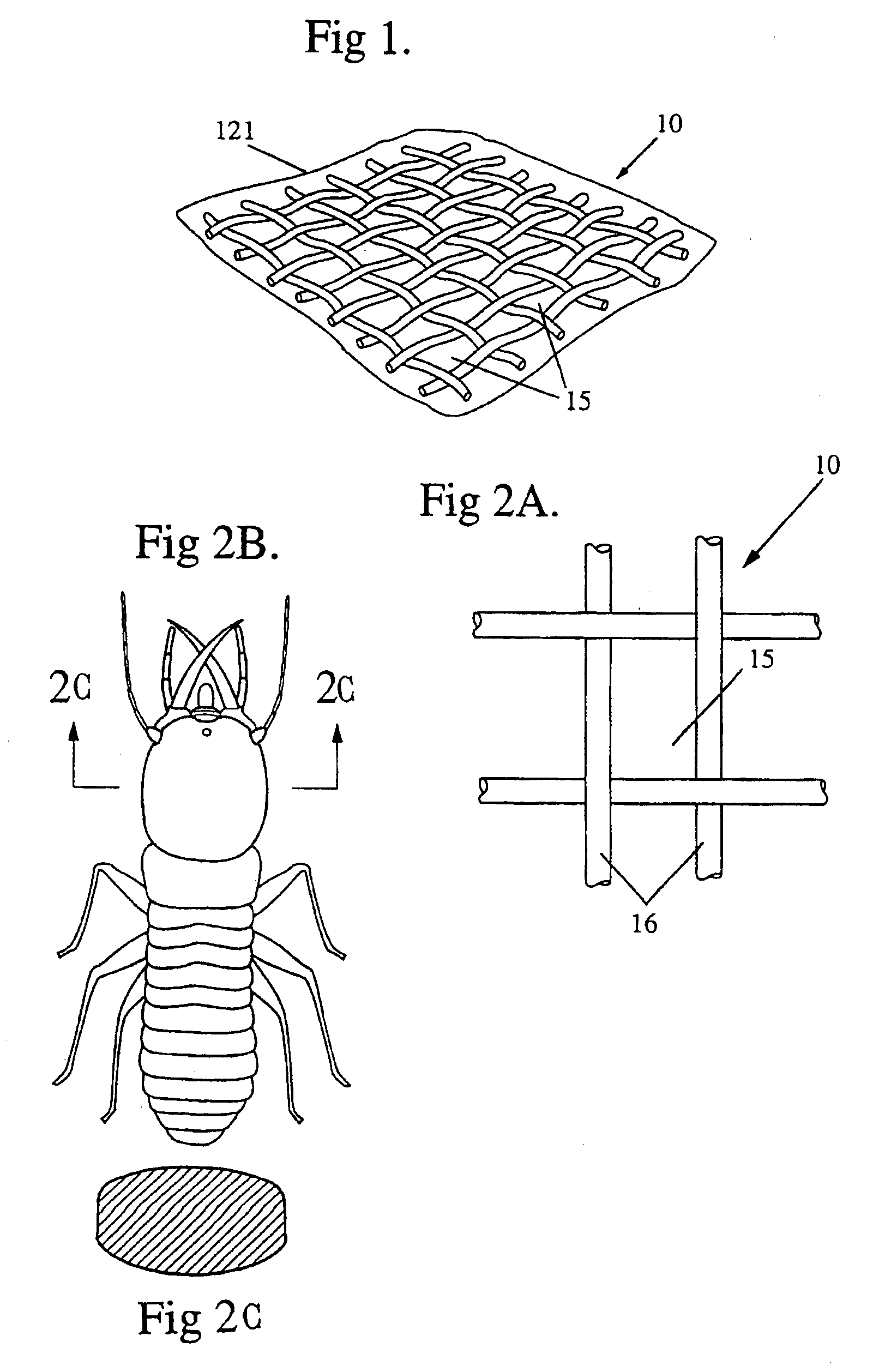

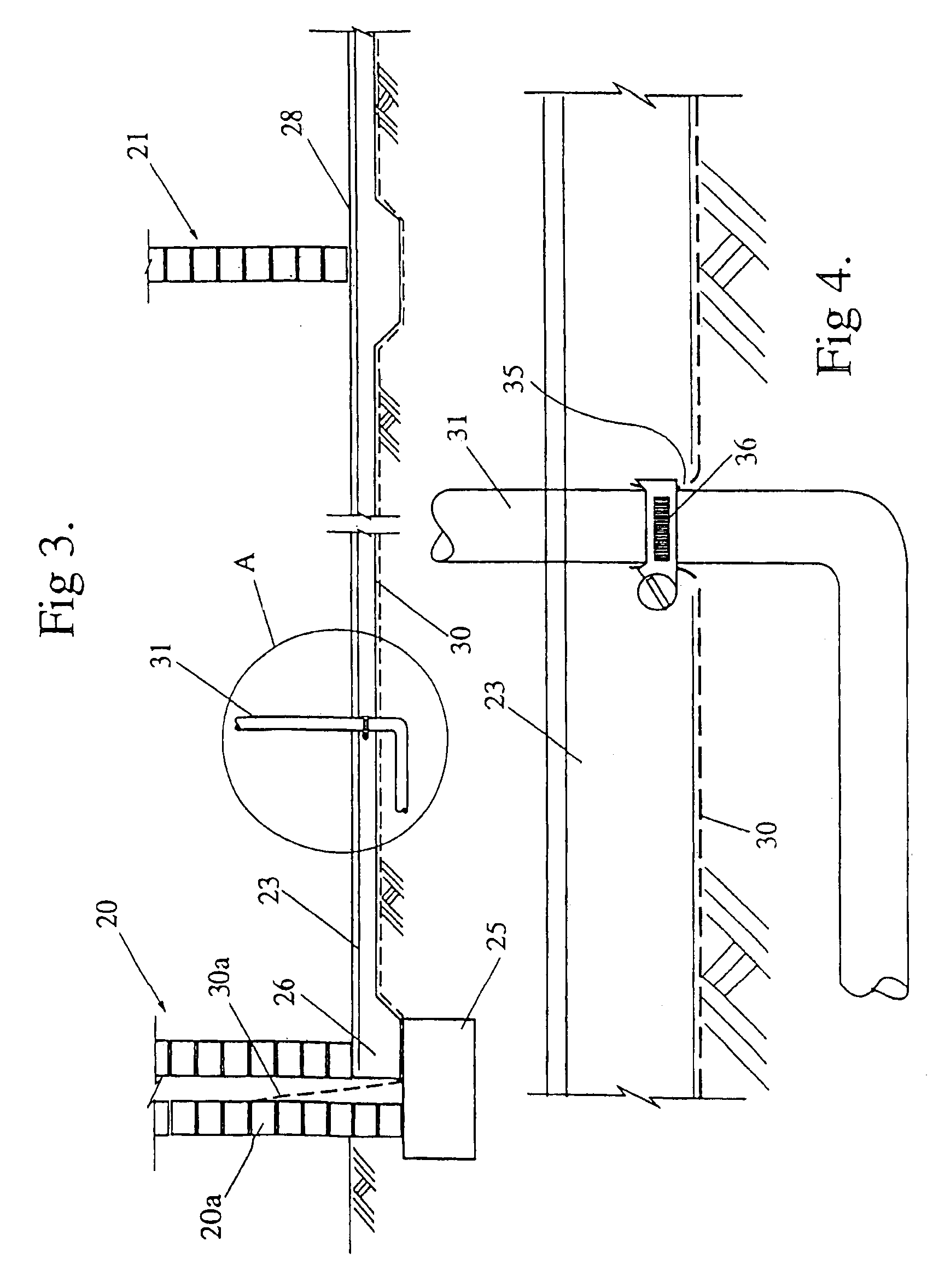

[0044]Referring now to FIGS. 1 and 2a-2c of the drawings, the termite barrier is in the form of a woven mesh 10 made of corrosion resistant stainless steel wires or filaments such as 304 grade stainless steel. The termite barrier may also include a flexible moisture impervious plastic sheet 121 formed to the woven mesh 10. Preferably, both sides of the woven mesh 10 are covered by a plastic sheet 121. The woven filaments form a series of pores or openings 15 in the mesh which are of a generally rectangular shape with the distance between the two more closely spaced sides 16 of the rectangle and the diagonal thereof is less than the maximum cross sectional dimensions of the head of the species of termite in respect of which the mesh is to form a barrier (FIG. 2c). For instance, the soldier termite of species Mastotermes darwiniensis, of northern Australia, has a maximum head width of 3.25 mm. To form a termite barrier for Mastotermes darwiniensis, the distance between the two more cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com