Method of fabricating Bragg gratings using a silica glass phase grating mask and mask used by same

a technology of phase grating and bragg grating, which is applied in the field of optical media, can solve the problems of low writing efficiency, high spatial and temporal coherence of laser sources, and gratings with a period similar to that of one half the wavelength of writing light,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

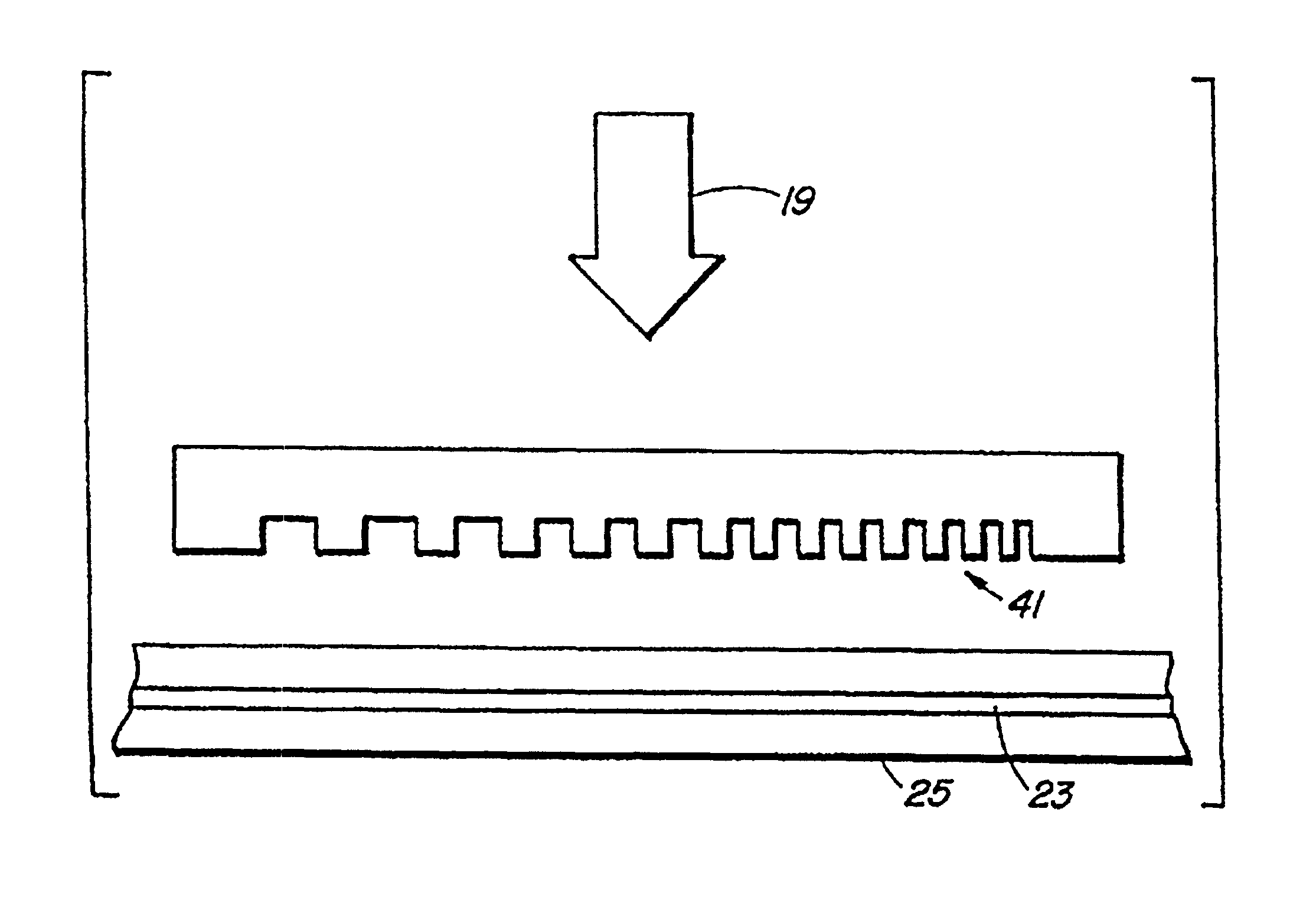

[0020]A phase grating slit-mask 1 is used in a precision photolithographic apparatus and is placed in contact, or near-contact, with an optical fiber 3, its grating striations 5 (as illustrated in magnification 6 of the mask) directed normal or near normal to the fiber axis. A UV light beam 7 from a suitable laser, a KrF excimer laser (249 nm) in a successful prototype is passed through the mask 1 by which it is phase modulated spatially and is diffracted to form an interference pattern 9A laterally (Bragg grating pitch) and along the incident laser beam direction 9B (Talbot pitch) as illustrated in magnification 11 of the core of the fiber.

[0021]The slit-mask preferably is comprised of a one dimensional surface-relief structure as shown at 6 fabricated in a high quality fused silica flat transparent to the KrF excimer laser radiation. The shape of the periodic surface-relief pattern of the phase mask preferably approximates a square wave in profile, as shown at 6. The amplitude of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap