Tonneau cover tension adjuster apparatus

a technology of tension adjuster and tonneau cover, which is applied in the direction of roofs, vehicle components, load transportation vehicles, etc., can solve the problems of tonneau covers that may stretch over time, poor aesthetics, and water puddling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

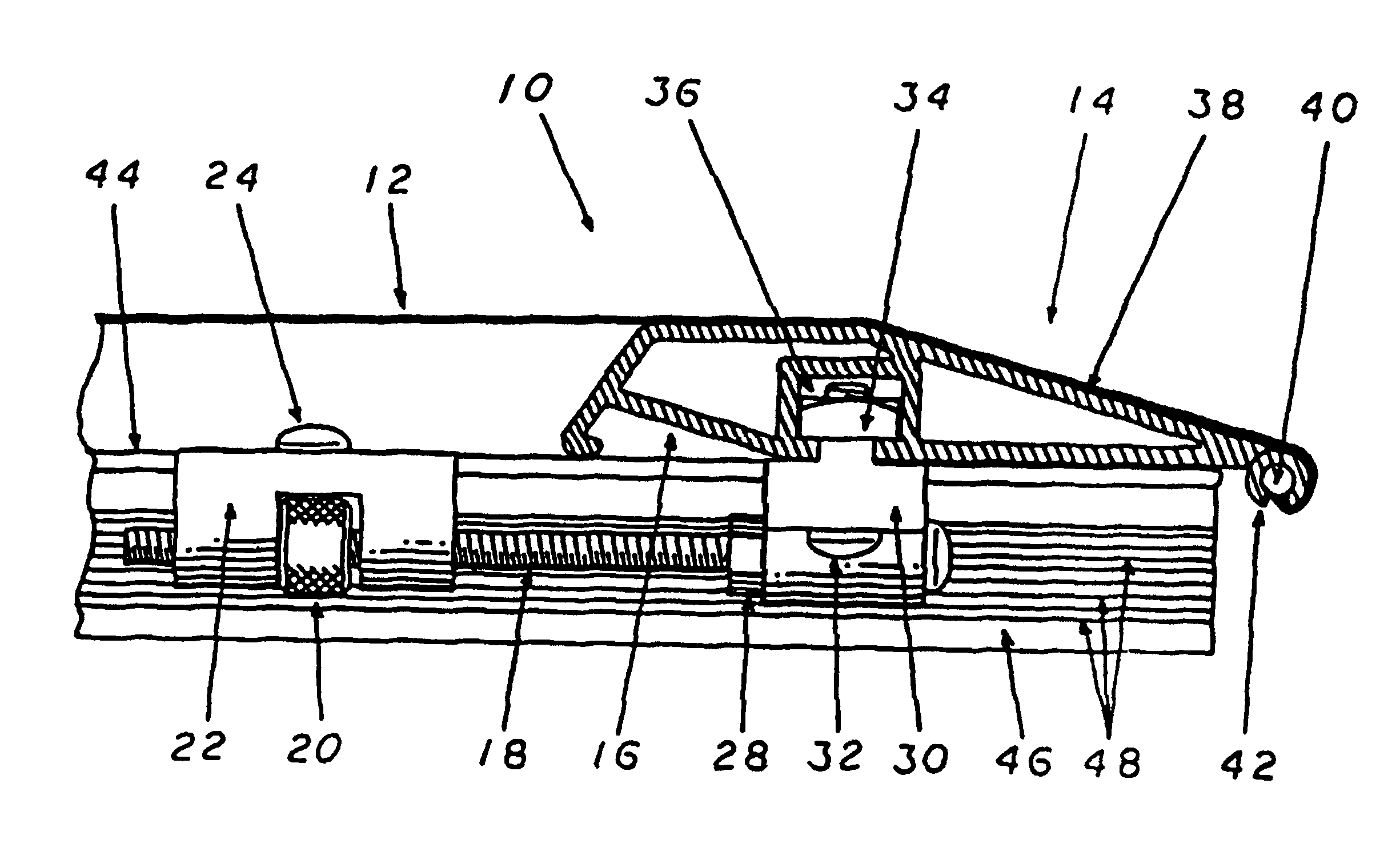

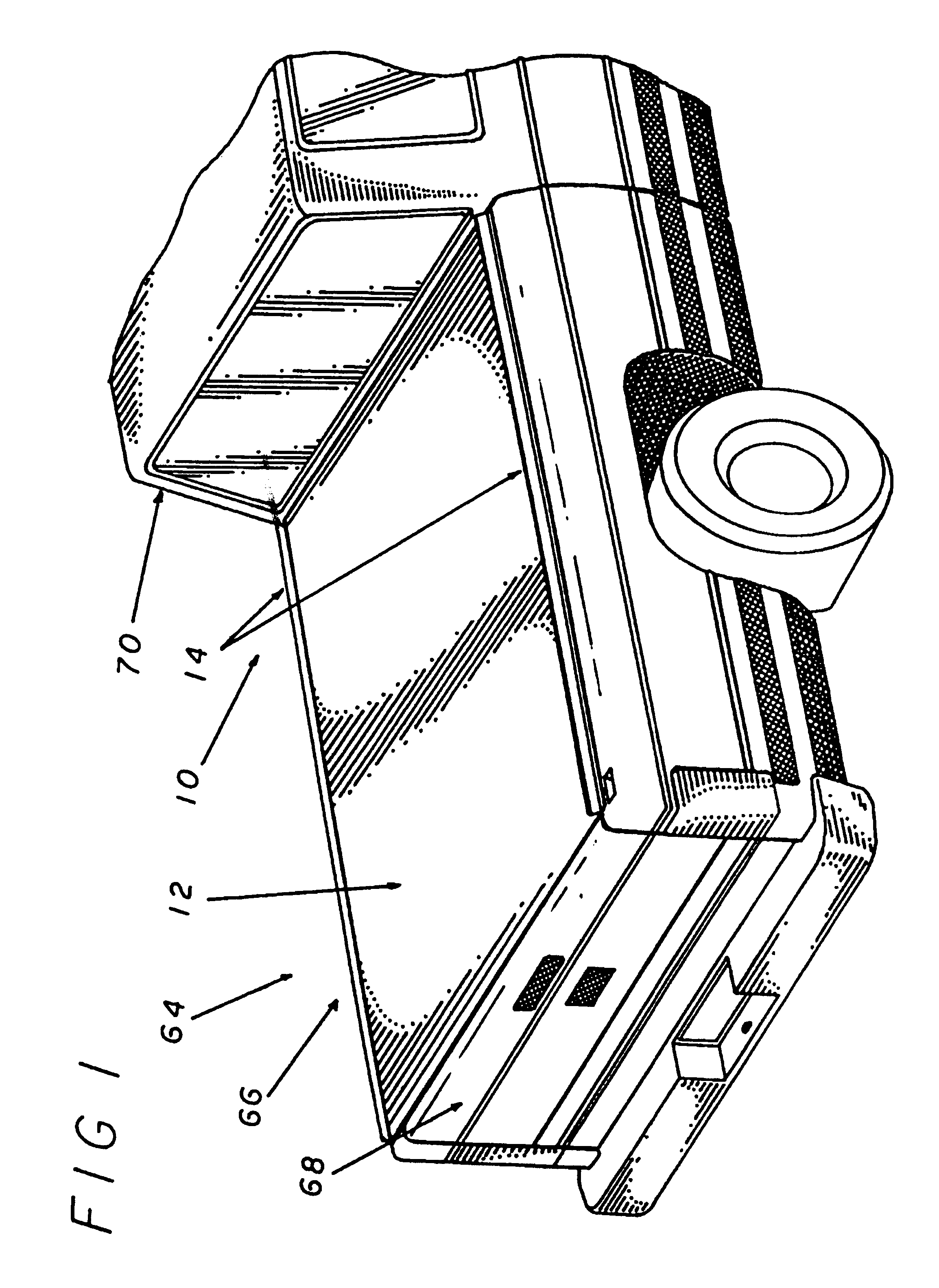

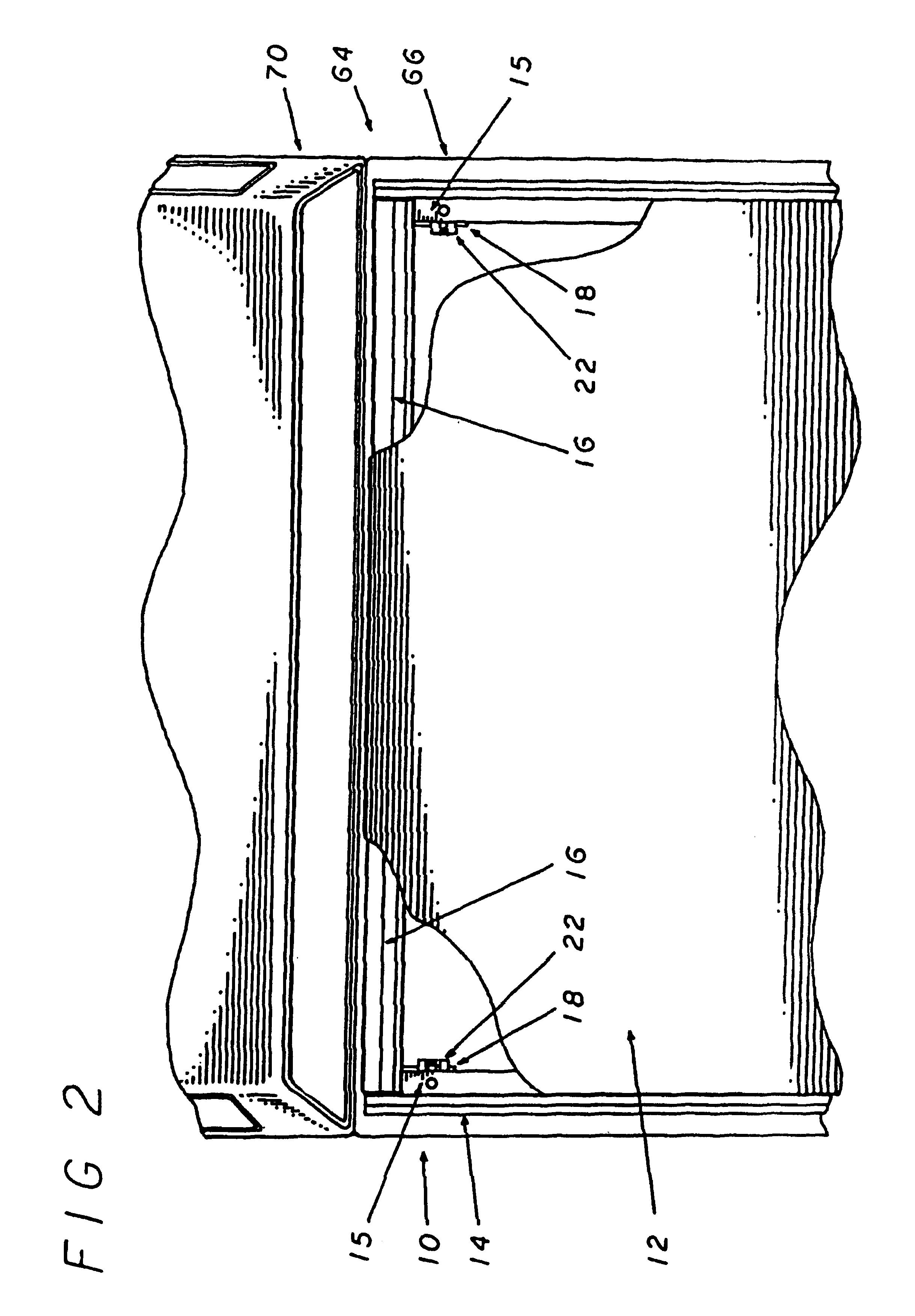

[0020]Referring now to the drawings, and more specifically to FIGS. 1 and 2, the tonneau cover tension adjuster apparatus 10 is made up of a tonneau cover 12 which fits over and covers the opening of a pickup truck box 66 of a typical pickup truck 64. The tonneau cover 12 extends from just behind the pickup cab 70 back to the tail gate 68 located at the most rearward portion of the truck box 66. This is accomplished by the use of a pair of apparatus side rails 14 which are attached to and run down the entire length of the upper outside edges of the truck box 66. The side rails 14 form the outside frame of the tonneau cover 12 and are the base upon which the cover tensioning rail 16 is attached. The side rails 14 also contain at their forward ends, a pair of graduated measuring scales 15 which give the user a point of reference to ensure that each side of the tensioning rail 16 places the same degree of tension on the tonneau cover 12.

[0021]The tensioning rail 16 provides the forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com