Tandem compressors with discharge valve on connecting lines

a technology of connecting line and discharge valve, which is applied in the direction of positive displacement liquid engine, lighting and heating apparatus, heating types, etc., can solve the problems of substantial leakage loss, reduced system performance, and insufficient fluid tightness of check valves to prevent leakage, etc., and achieve the effect of eliminating leakage losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

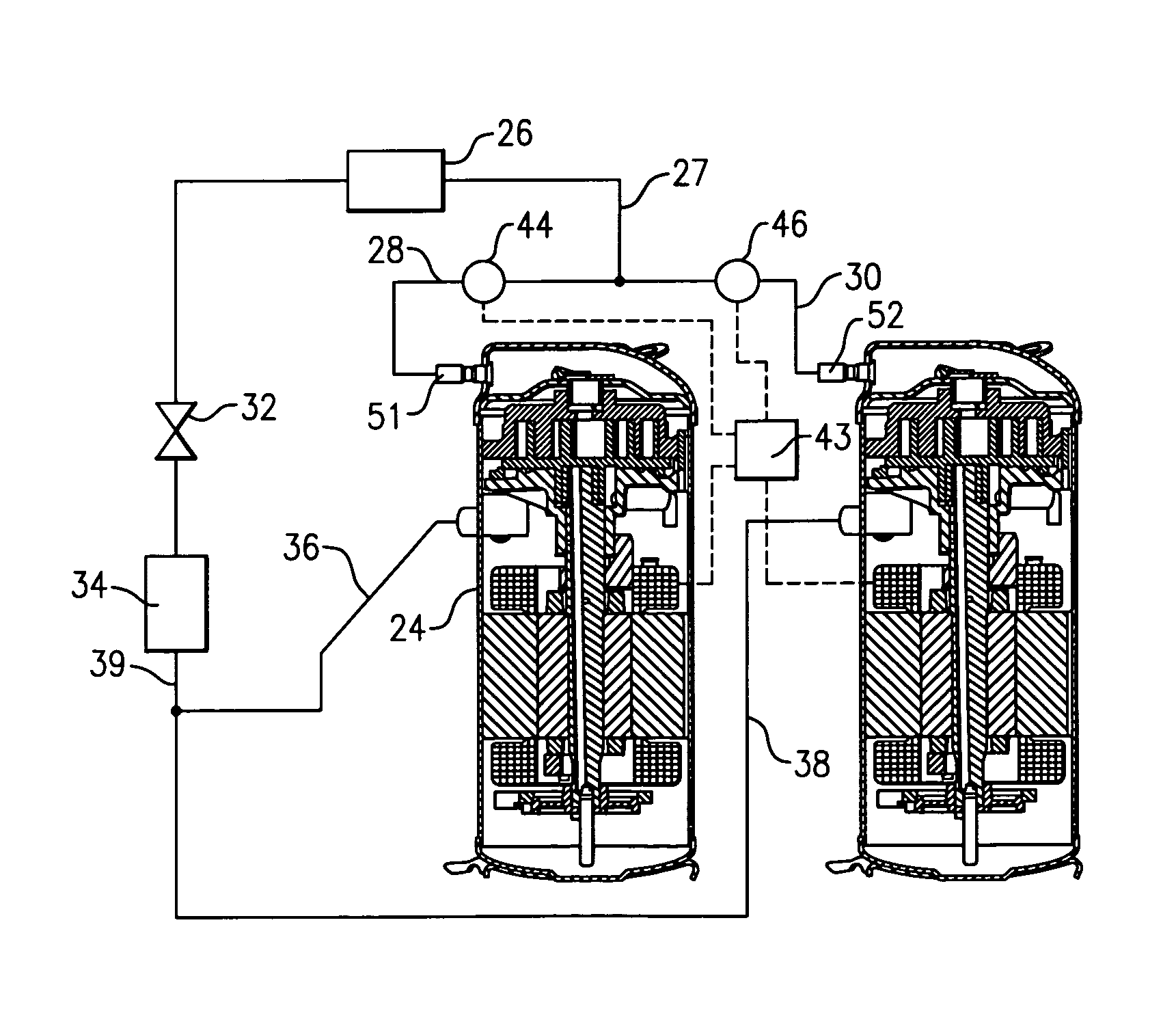

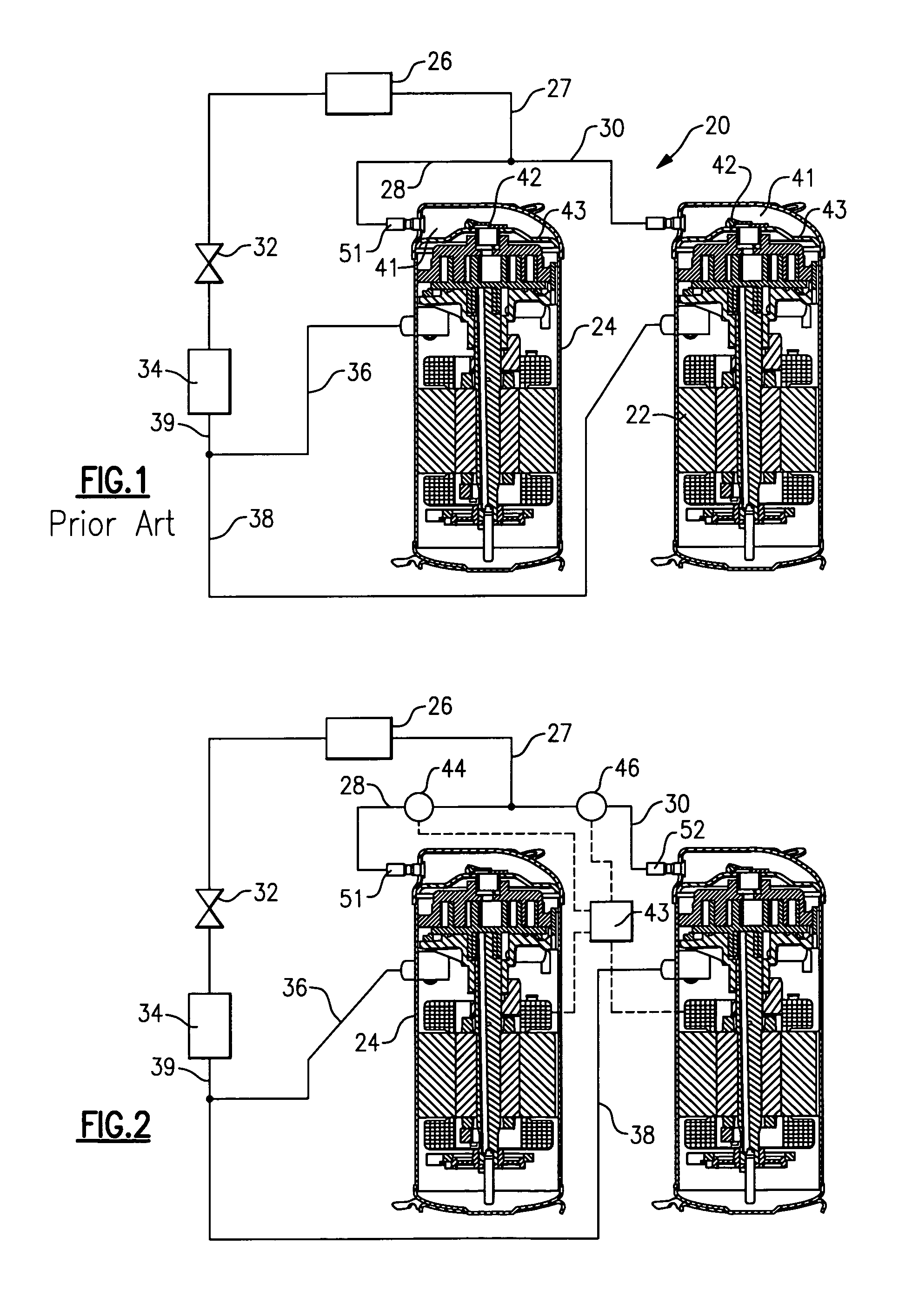

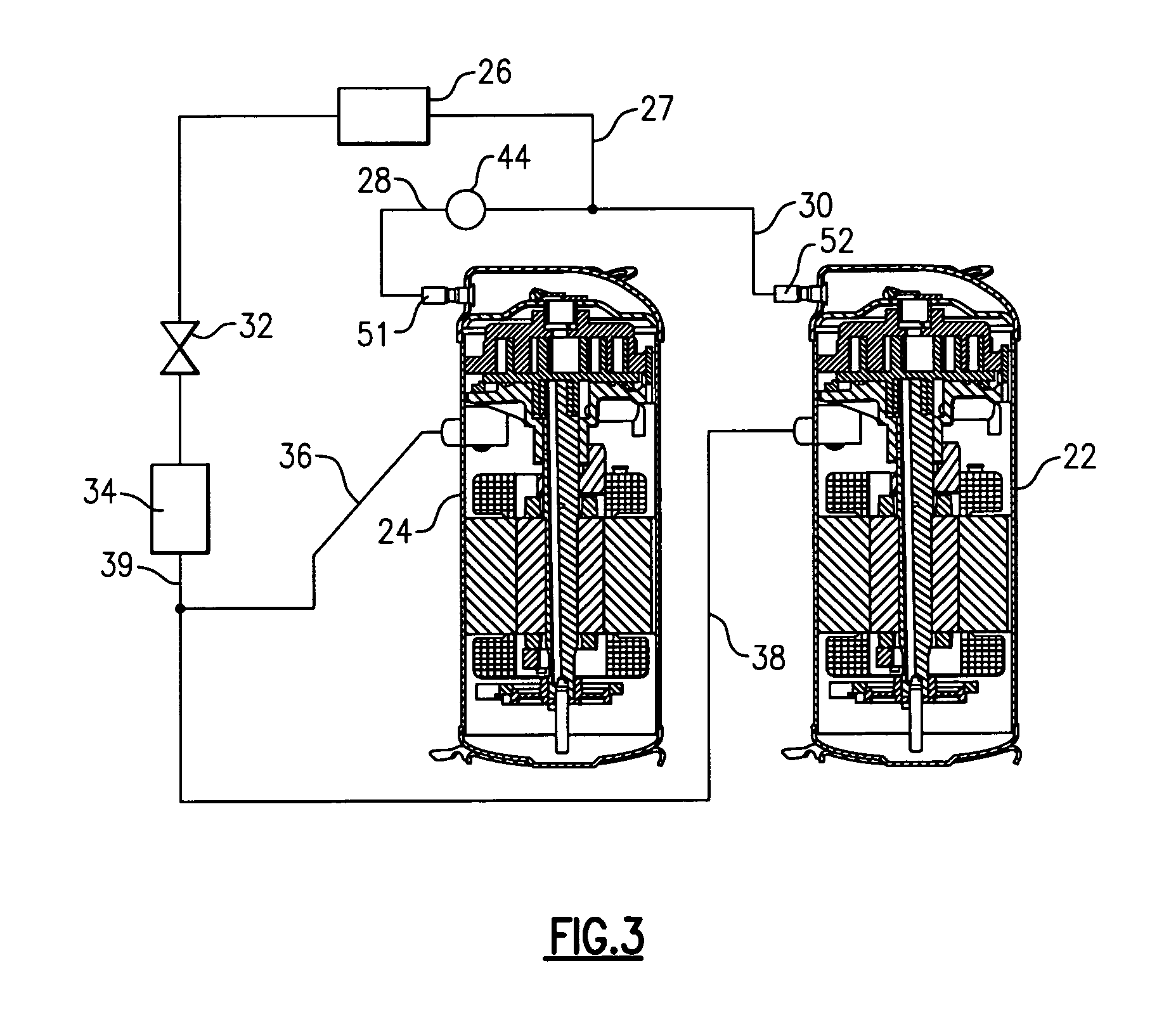

[0011]FIG. 1 shows a prior art refrigerant system 20 incorporating a pair of tandem compressors 22 and 24. As shown, the compressors 22 and 24 are preferably scroll compressors.

[0012]The compressors are provided with discharge ports (tubes) 51 and 52 that form a part of respective flow connecting discharge lines 28 and 30 leading to a central connecting discharge line 27 that communicates compressed refrigerant to condenser 26. From the condenser 26, refrigerant passes to an expansion device 32, and to an evaporator 34. From the evaporator 34, the refrigerant returns through common suction line 39 that branches off to individual suction lines 36 and 38 to the interior shell of each compressor.

[0013]As is known, an upper part 41 of the compressor is at a discharge pressure. A check valve 42 is typically placed such as in a separator plate 43 within the scroll compressor.

[0014]In the prior art, a control for the tandem compressors may shutdown one of compressors 22 and 24 when a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com