Small-size hydraulic buffer for elevator

A hydraulic buffer and hydraulic buffer technology, applied in the field of buffer devices, can solve the problems of unsatisfactory buffer process performance, limited buffer mass range, inability to reduce height, etc., achieving light weight, saving building installation space, and small inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

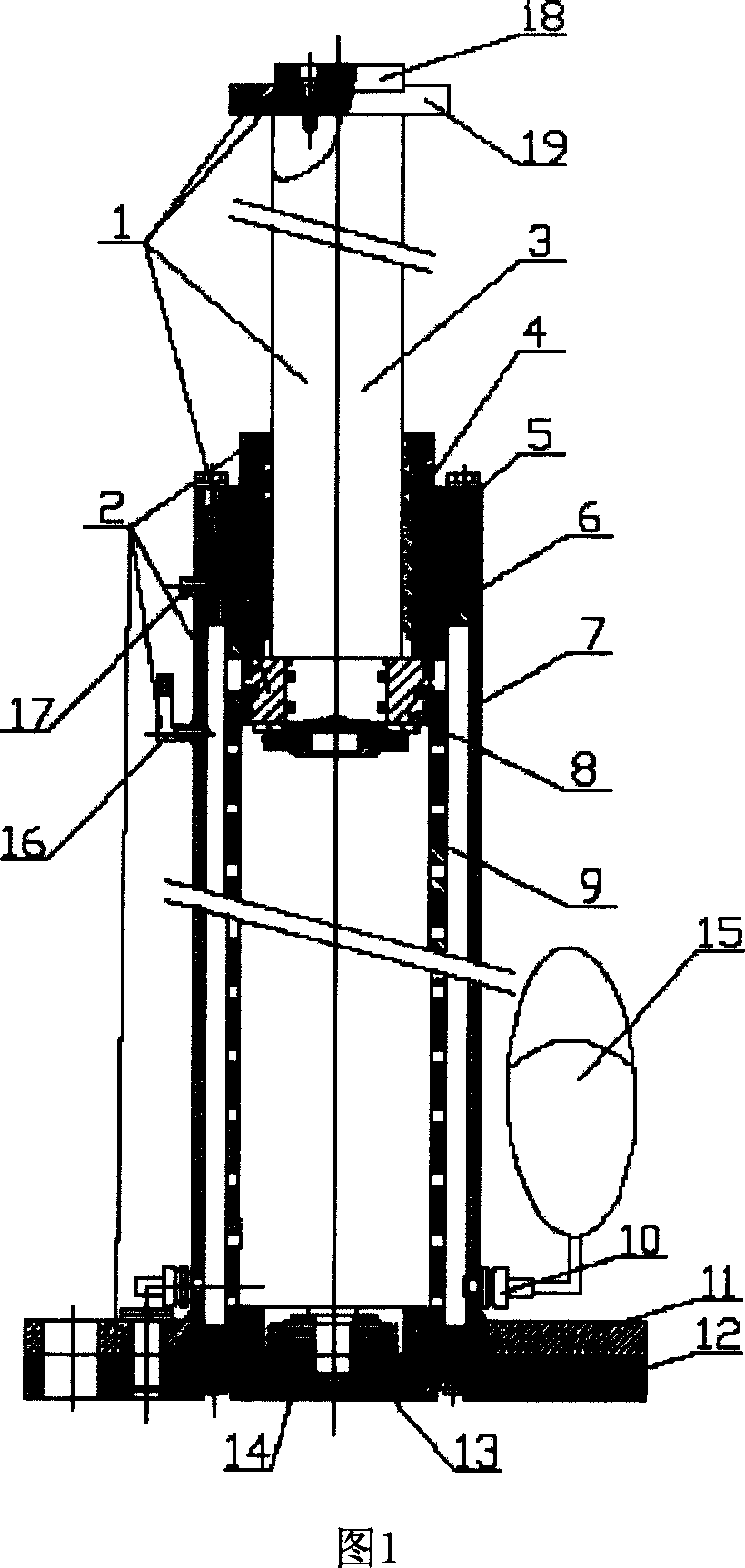

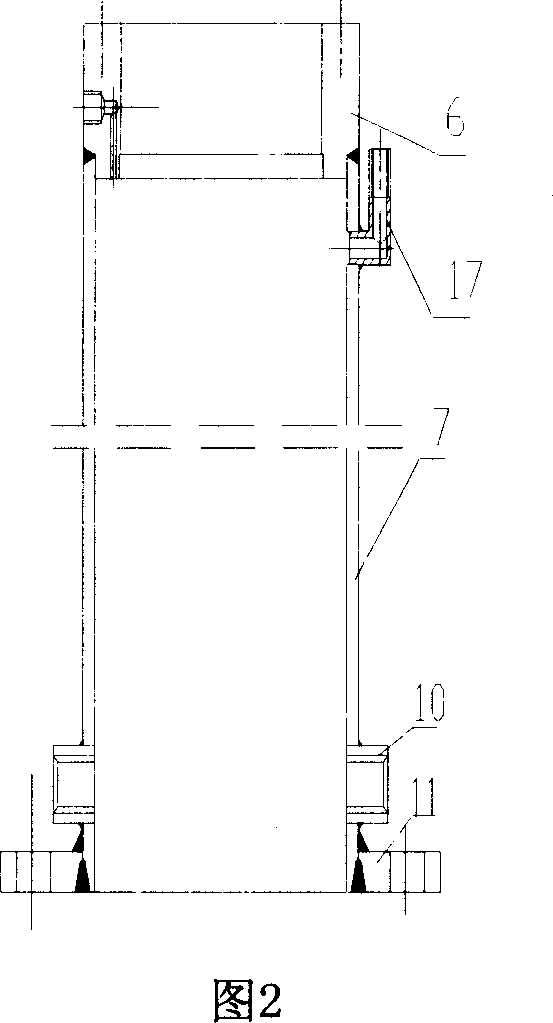

[0016] As shown in Figures 1 and 2, the present invention includes: a piston assembly 1, an outer cylinder body assembly 2, a cylinder head 4, an inner cylinder body 9, a lower base 12, an inner cylinder base 13, a disc spring 14 and an accumulator 15. The connection relationship is as follows: the accumulator 15 is connected with the outer cylinder assembly 2, the inner cylinder 9 is sealed with the piston assembly 1 to form a closed inner cavity through the positioning seal of the inner cylinder base 13 and the fixation of the lower base 12, and the cylinder head 4 Fixed on the outer cylinder body assembly 2, the Belleville spring 14 is fixed on the inner cylinder base 13.

[0017] The outer cylinder assembly 2 is made up of an outer cylinder head 6, an outer cylinder 7, an upper base 11, and a nozzle 16. The outer cylinder 7 is welded on the upper base 11, the outer cylinder head 6 is welded on the outer cylinder 7, and the oil nozzle 16 is welded on the outer cylinder 7 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com