Electromotor of possessing structure for rotational balancing rotor

A rotational balance and motor technology, applied in the field of motors, can solve problems such as affecting the rotational efficiency of the inner rotor and interfering with the alternating excitation efficiency of the outer stator group, and achieve the effects of improving rotational stability, maintaining rotational balance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

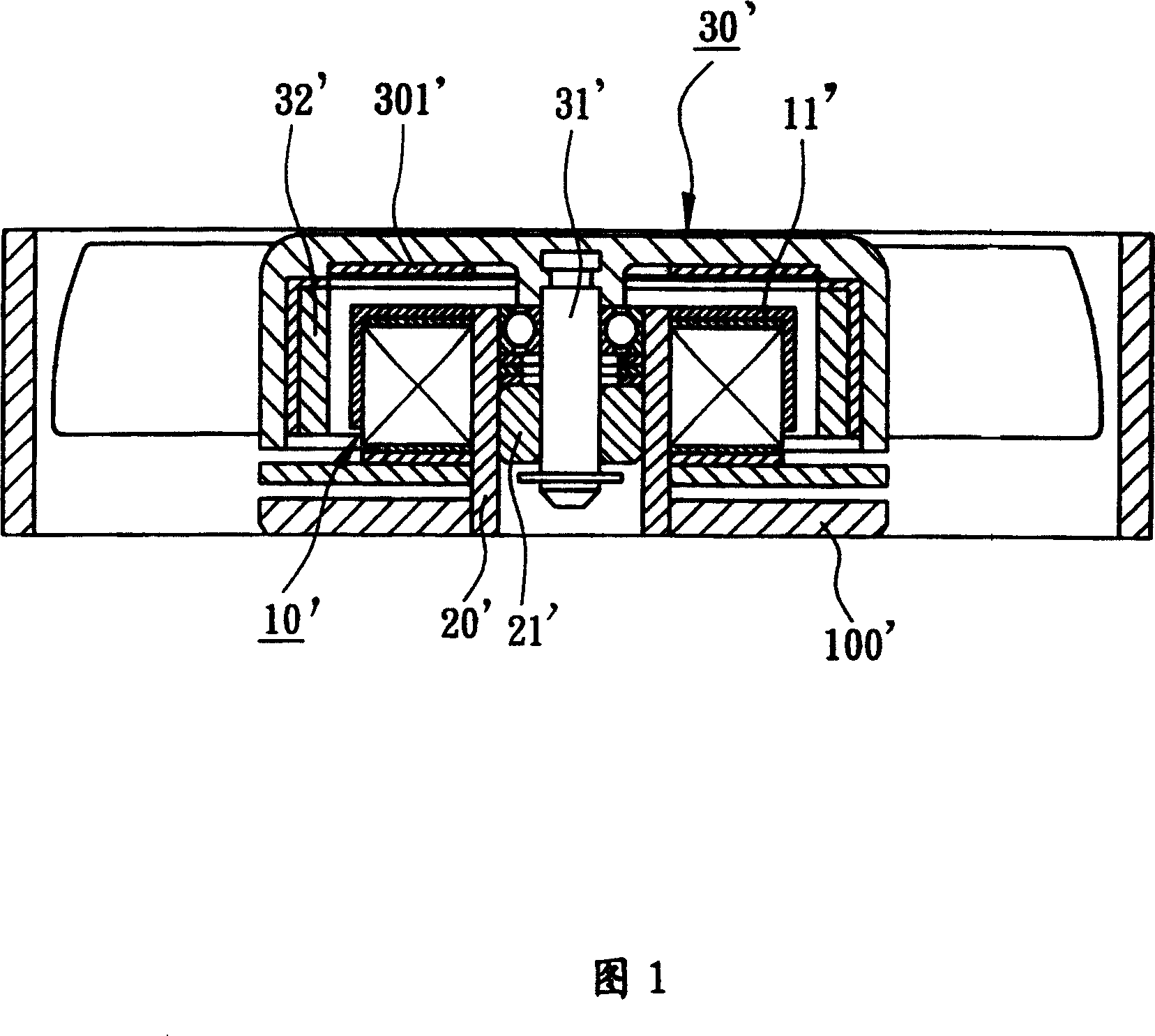

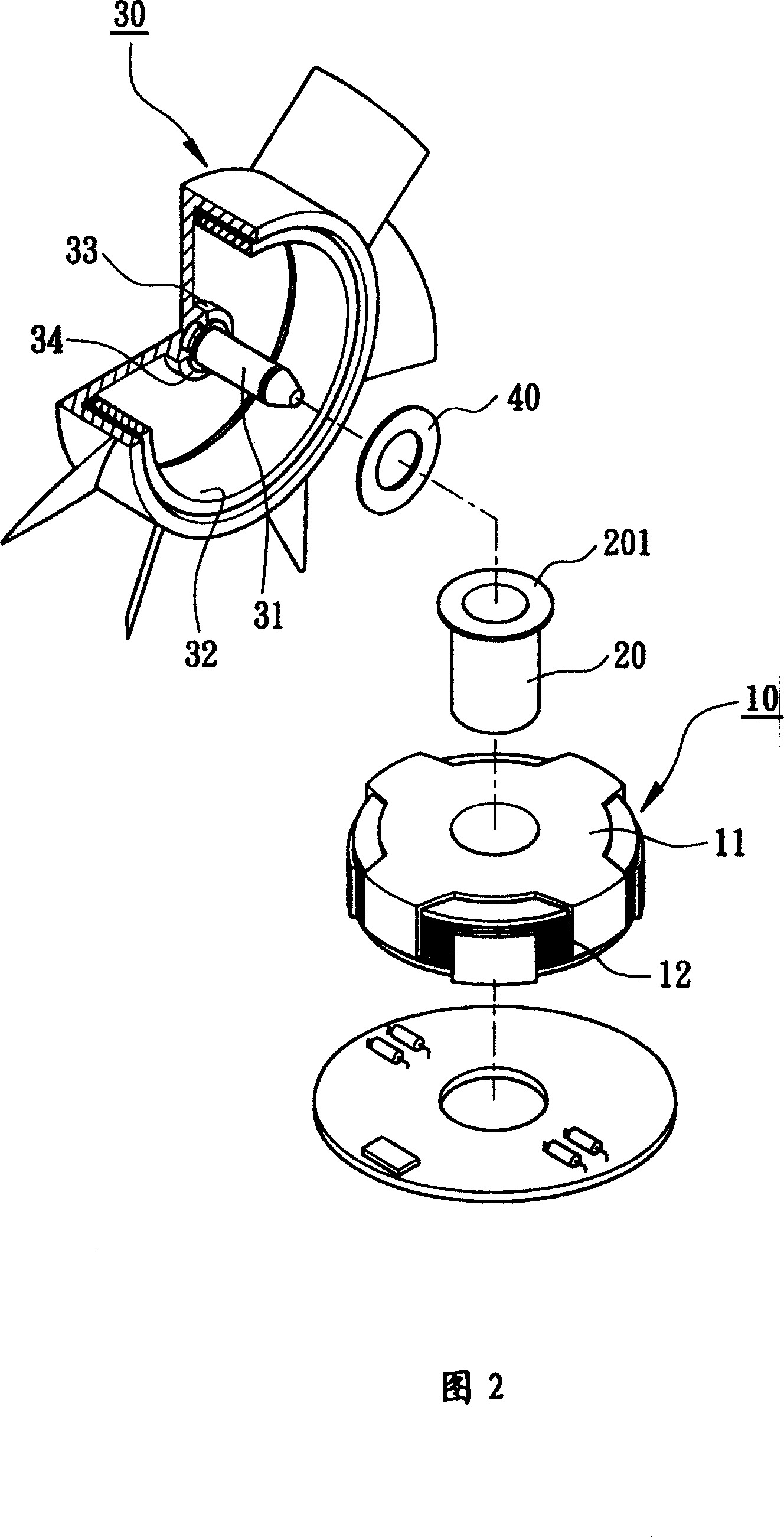

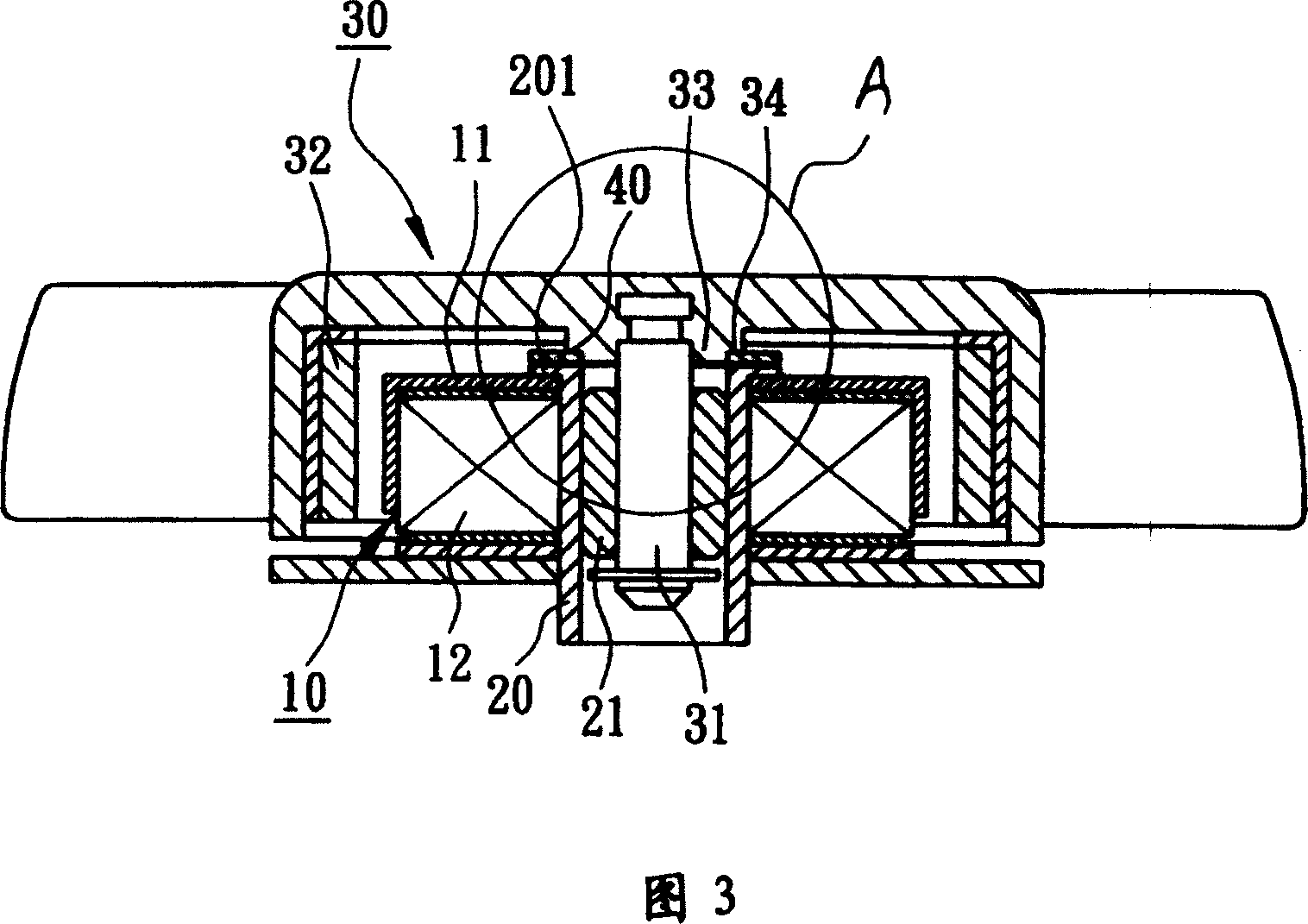

[0036] As shown in FIG. 2 , FIG. 3 and FIG. 4 , the present invention includes a stator 10 , a magnetic sensing part 201 , a rotor 30 and a balance magnet 40 .

[0037] The stator 10 is provided with at least one pole piece 11 , at least one coil 12 that induces the pole piece 11 to generate alternating excitation when alternately energized, and a shaft tube 20 passing through the center axis hole of the stator 10 . The shaft tube 20 is made of a magnetically sensitive material, and a radial flange is disposed on the top of the shaft tube 20 to form the magnetically sensitive portion 201 . The shaft tube 20 fastens and fixes the stator 10 by means of radial flanges, so as to facilitate fixing the stator 10 in a proper position, such as in a housing of a cooling fan.

[0038] The rotor 30 is provided with a shaft 31 , a ring magnet 32 and a shaft seat 33 . The shaft seat 33 protrudes from the center of the lower surface of the rotor 30 , and the shaft seat 33 can form a shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com