Combined structure of motor axle tube

A motor shaft and structure technology is applied in the field of combined structure of motor shaft tubes, which can solve the problems of low assembly reliability of bearings 4, easy entry of dust, and excessively large gaps of shaft tubes 11.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

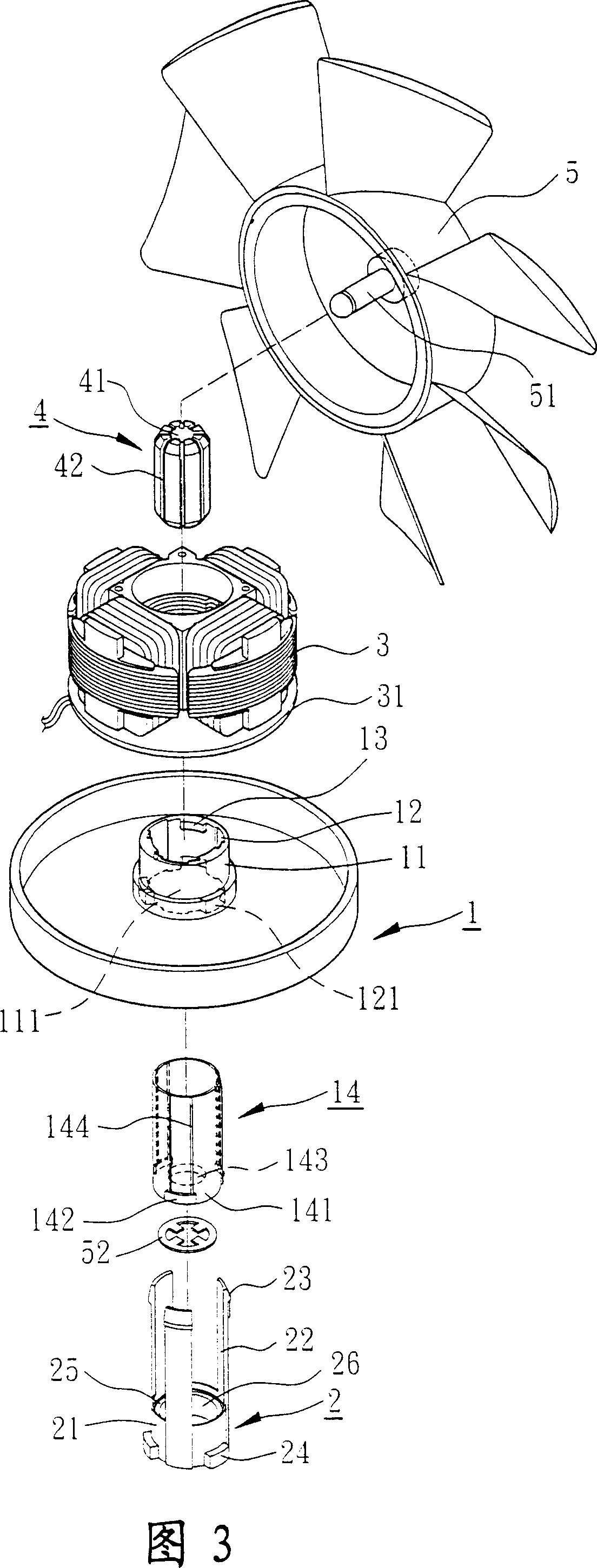

[0040] In order to make the technical problems, features, and advantages of the present invention more clearly understood, preferred embodiments of the present invention will be exemplified below in detail with accompanying drawings.

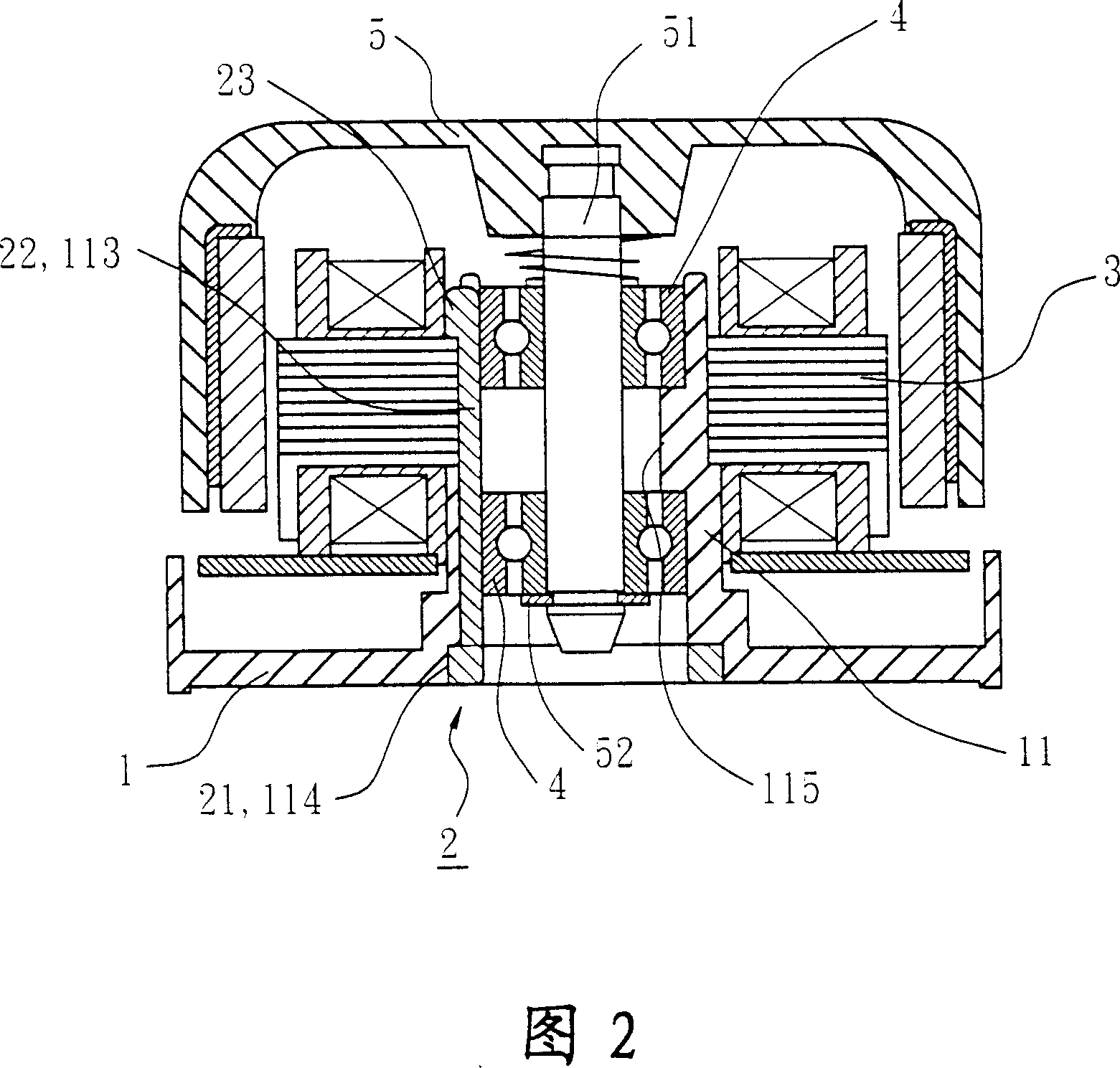

[0041] Fig. 3 discloses an exploded perspective view of the combined structure of the motor shaft tube of the present invention; Fig. 4 reveals a partial sectional view of the combined structure of the motor shaft tube of the present invention; Fig. 5 discloses a partial combined sectional view of the combined structure of the motor shaft tube of the present invention; Fig. 6 reveals A partial combined top view of the combined structure of the motor shaft tube of the present invention; and FIG. 7 shows a combined cross-sectional view of the combined structure of the motor shaft tube of the present invention.

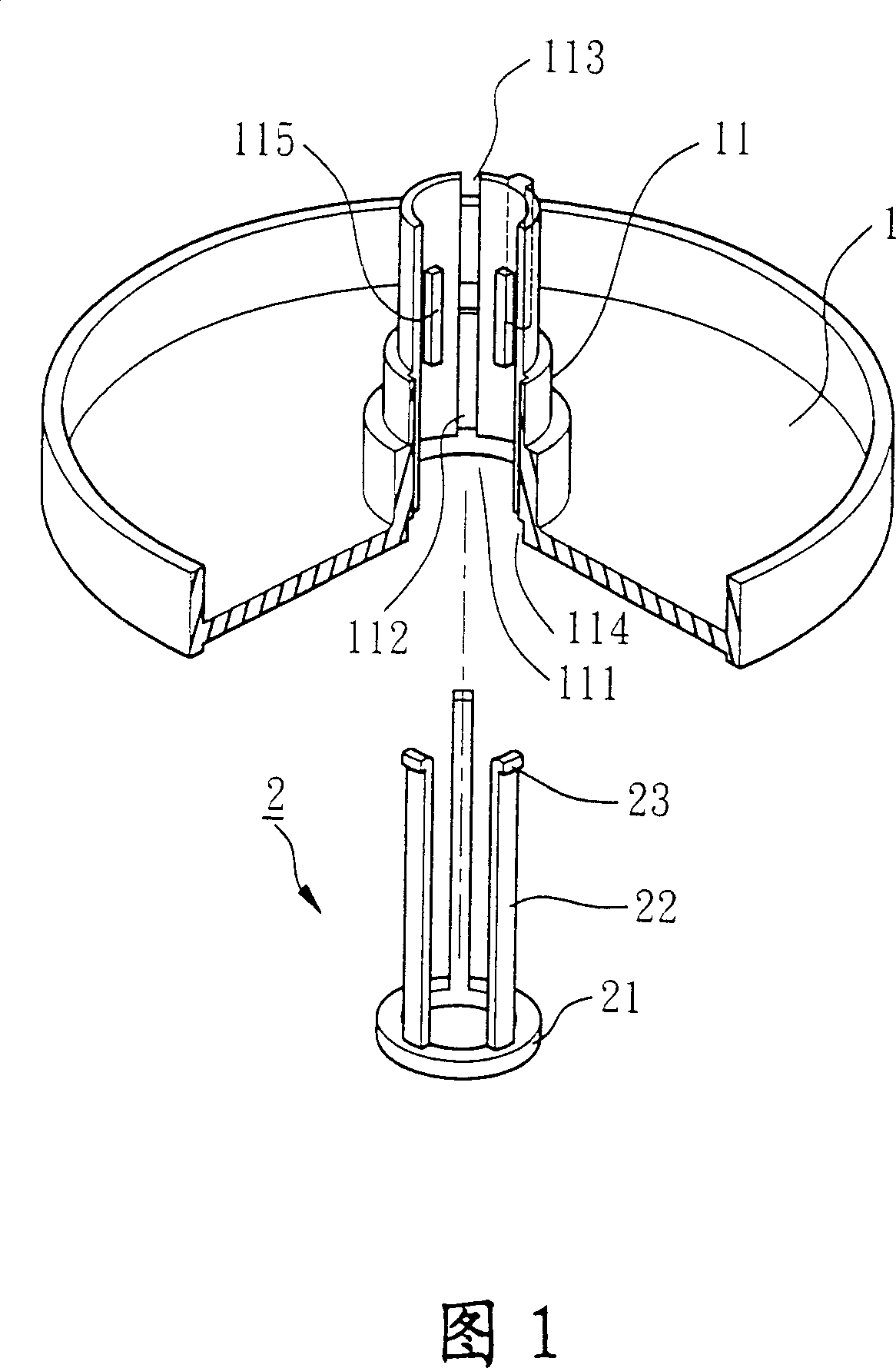

[0042] Some components of the combined structure of the motor shaft tube of the present invention are the same as those of the known combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com