Combination structure of motor axle tube

A motor shaft and shaft tube technology, which is applied in the field of combined structure of motor shaft tubes, can solve problems such as insufficient assembly reliability, shortened motor service life, and reduced service life, so as to maintain rotor rotation balance and rotation stability, and increase bearing capacity. The effect of improving service life and assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

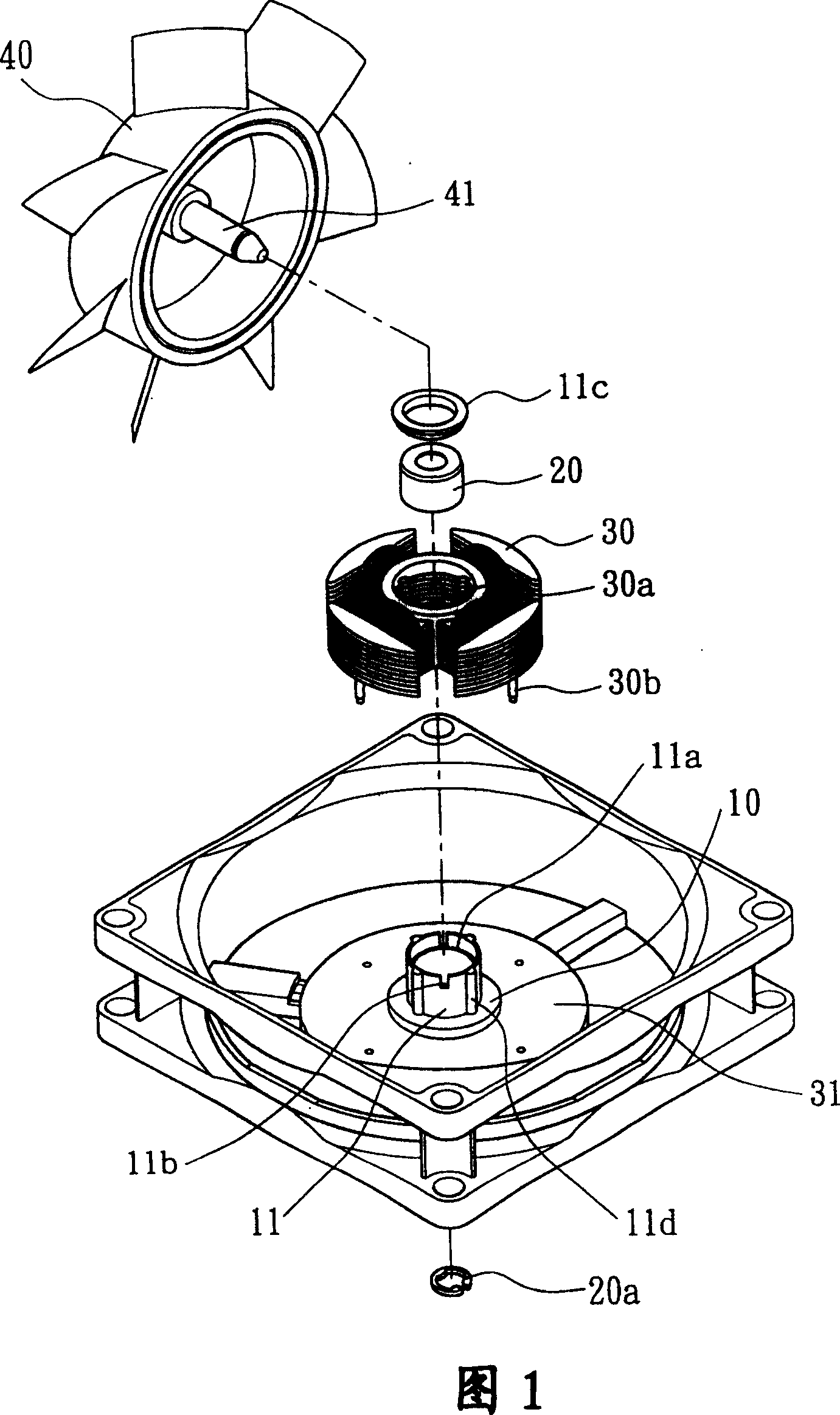

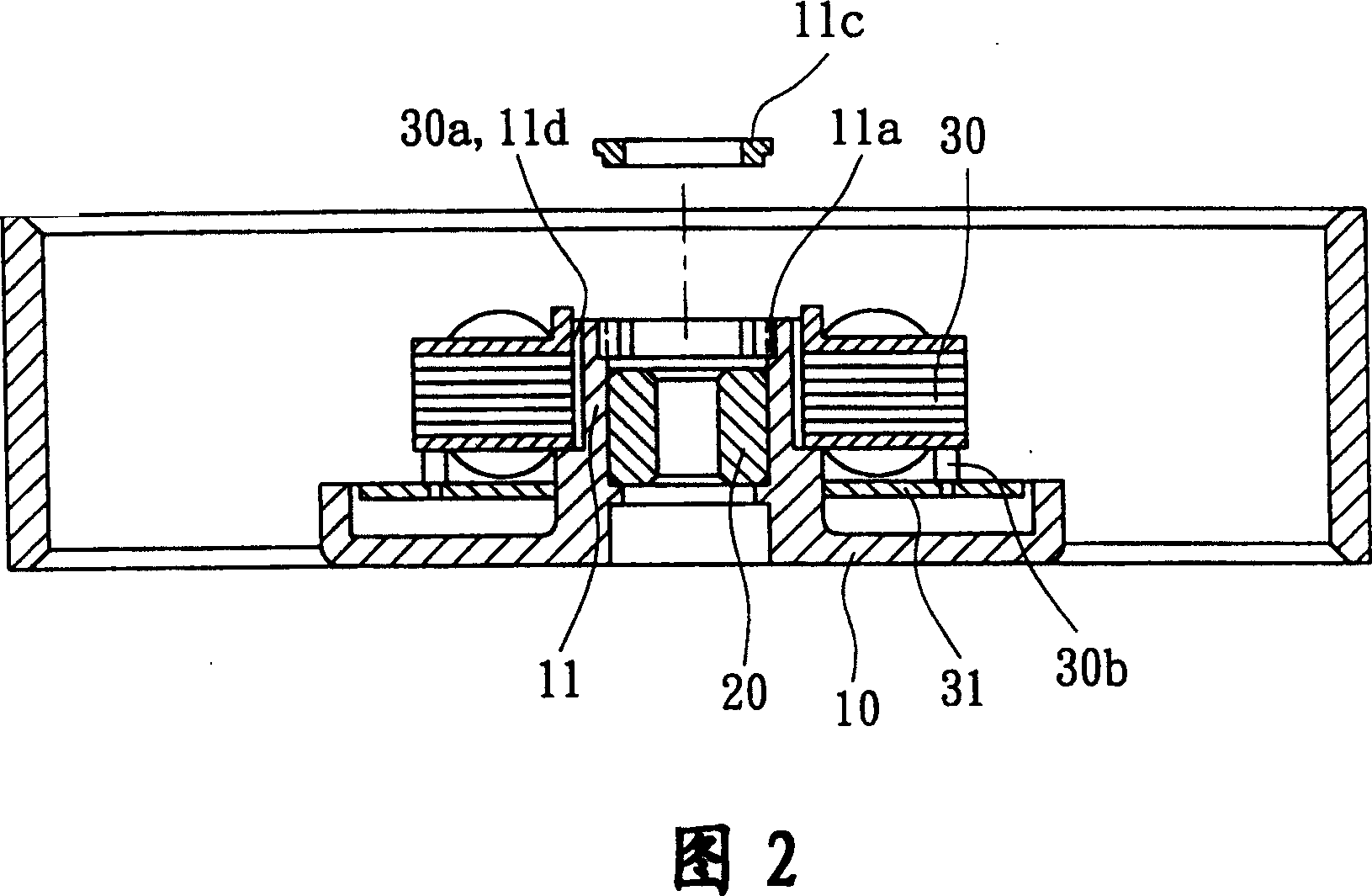

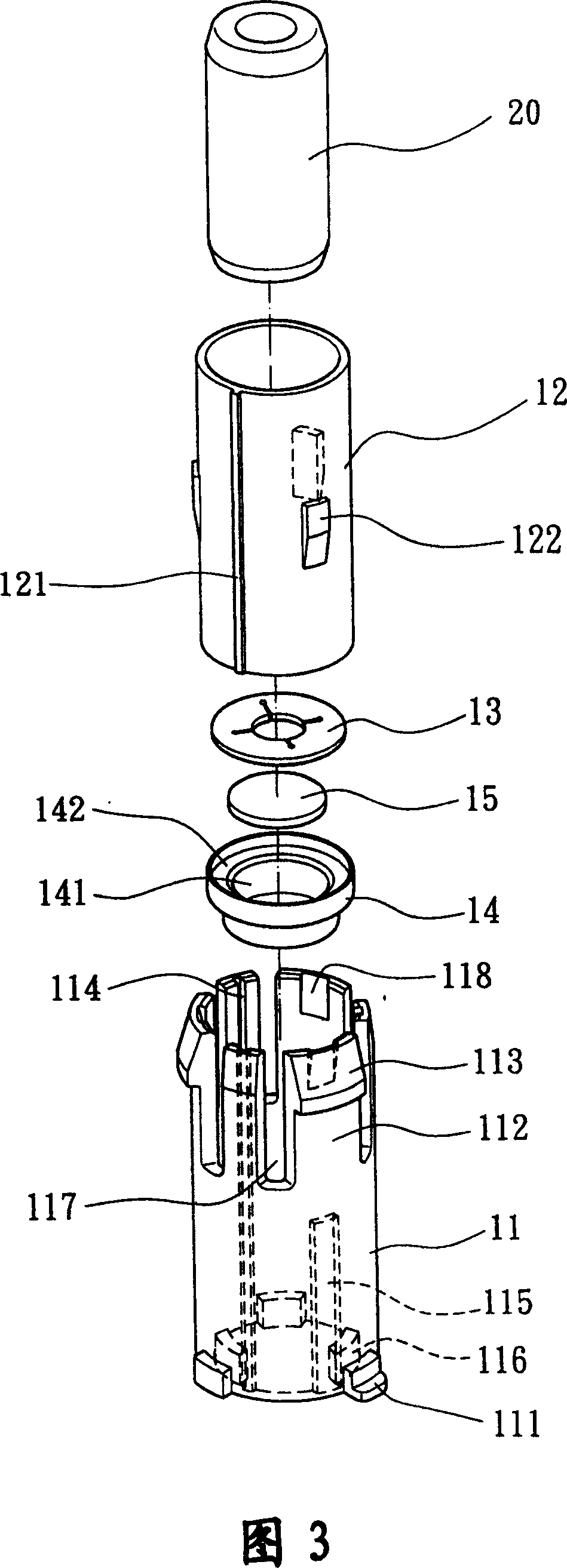

[0058] In order to make the above and other objects, features, and advantages of the present invention more clearly understood, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description:

[0059] Fig. 3 discloses an exploded perspective view of the combined structure of the motor shaft tube of the first embodiment of the present invention; Fig. 4 discloses an assembled perspective view of the combined structure of the motor shaft tube of the first embodiment of the present invention; Fig. 5 discloses the present invention along the line 5 of Fig. 4 - Combination sectional view of line 5; FIG. 6 discloses a combined sectional view of the combined structure of the motor shaft tube of the first embodiment of the present invention; FIG. 7 discloses an exploded perspective view of the combined structure of the motor shaft tube of the second embodiment of the present invention; FIG. 8 disclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com