Motor structure

A structure and motor technology, applied in the field of motor balance structure, can solve the problems of reducing the actual balance effect of the magnetic induction part, difficult to precisely align and assemble the magnetic induction part, reducing the magnetic attraction balance force, etc., so as to ensure the rotation efficiency and the actual balance. Efficiency, maintaining rotational balance and rotational stability, simplifying the effect of the balance structure process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above and other objects, features and advantages of the present invention more clearly understood, preferred embodiments of the present invention will be exemplified below and described in detail in conjunction with the accompanying drawings.

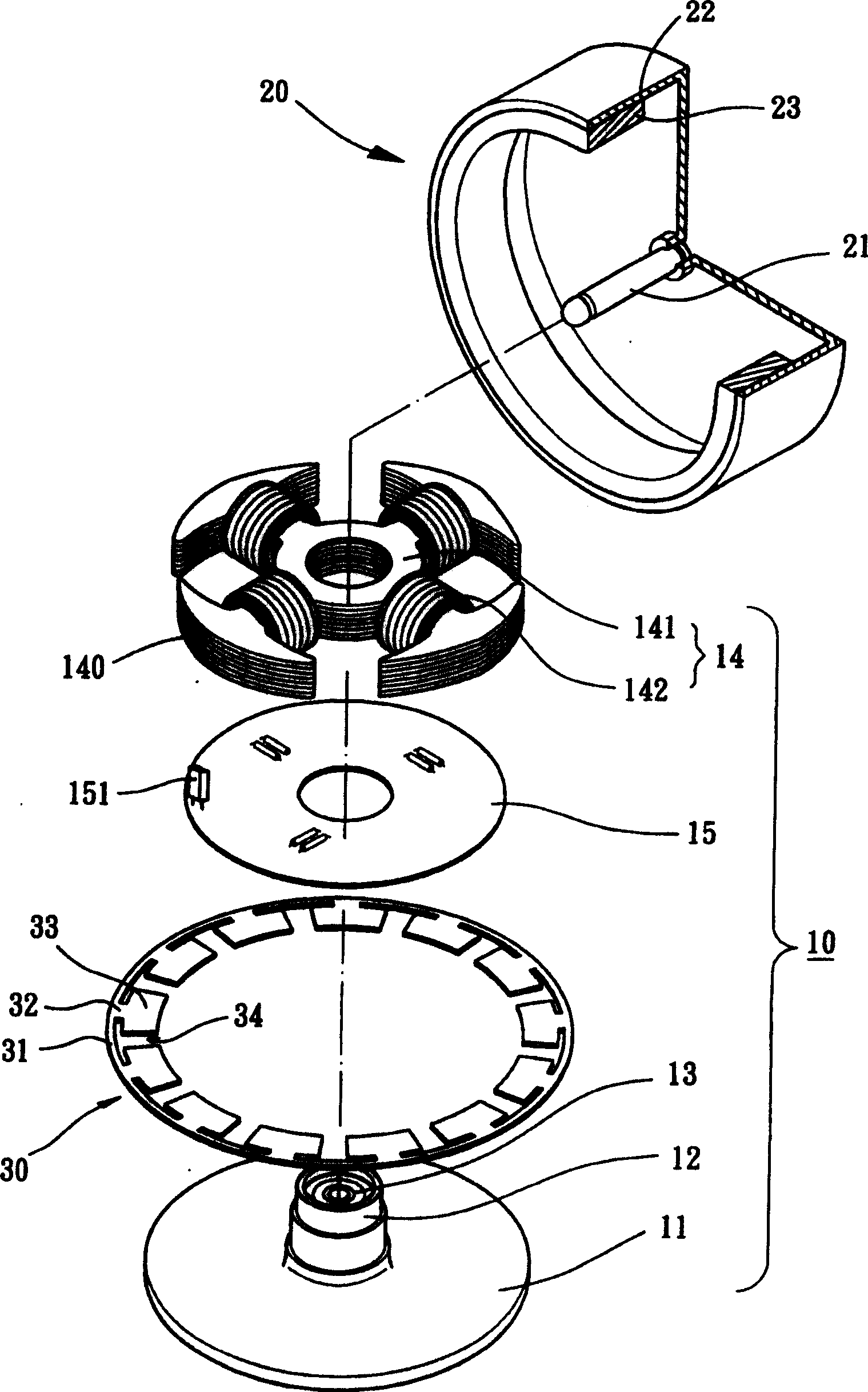

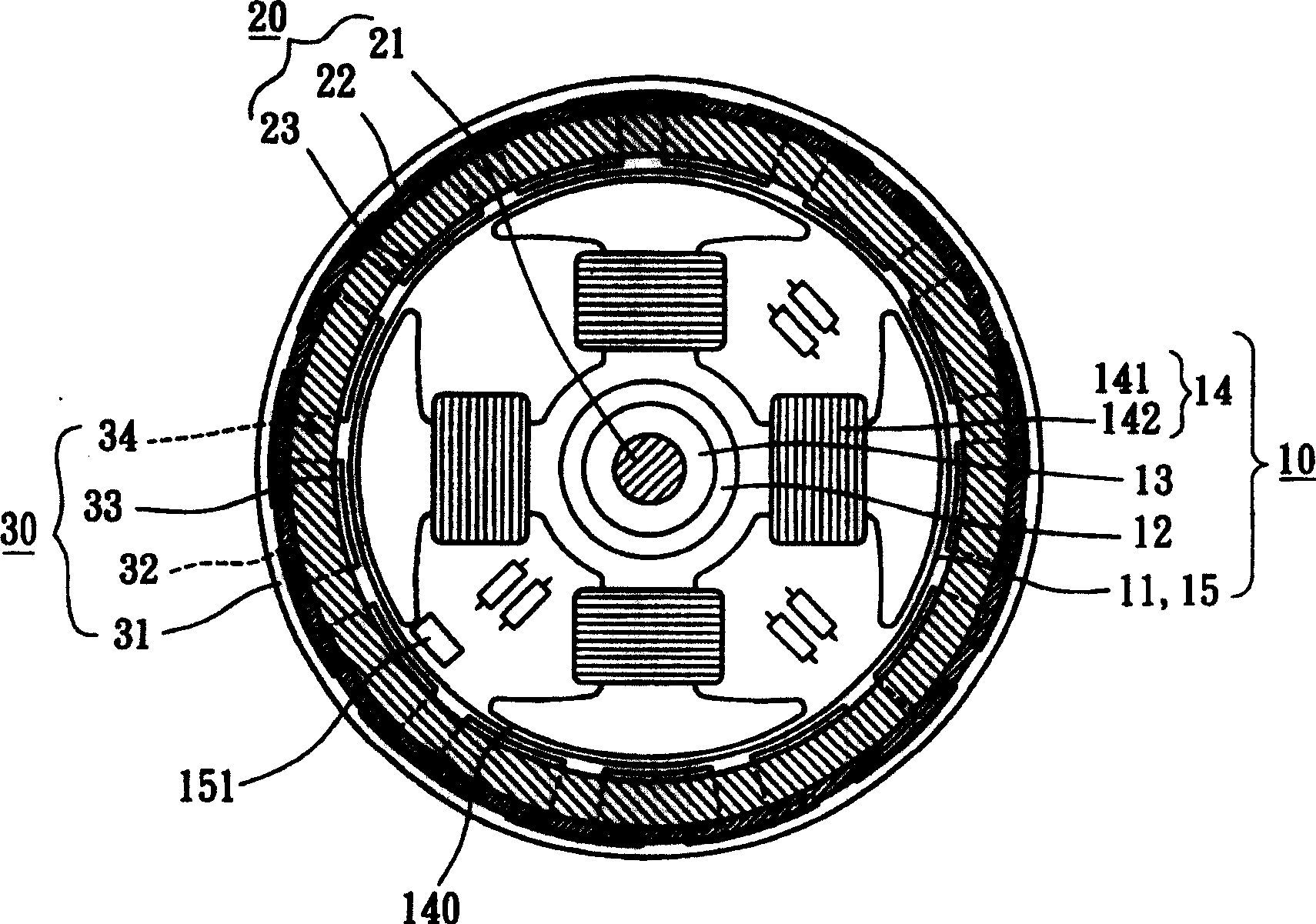

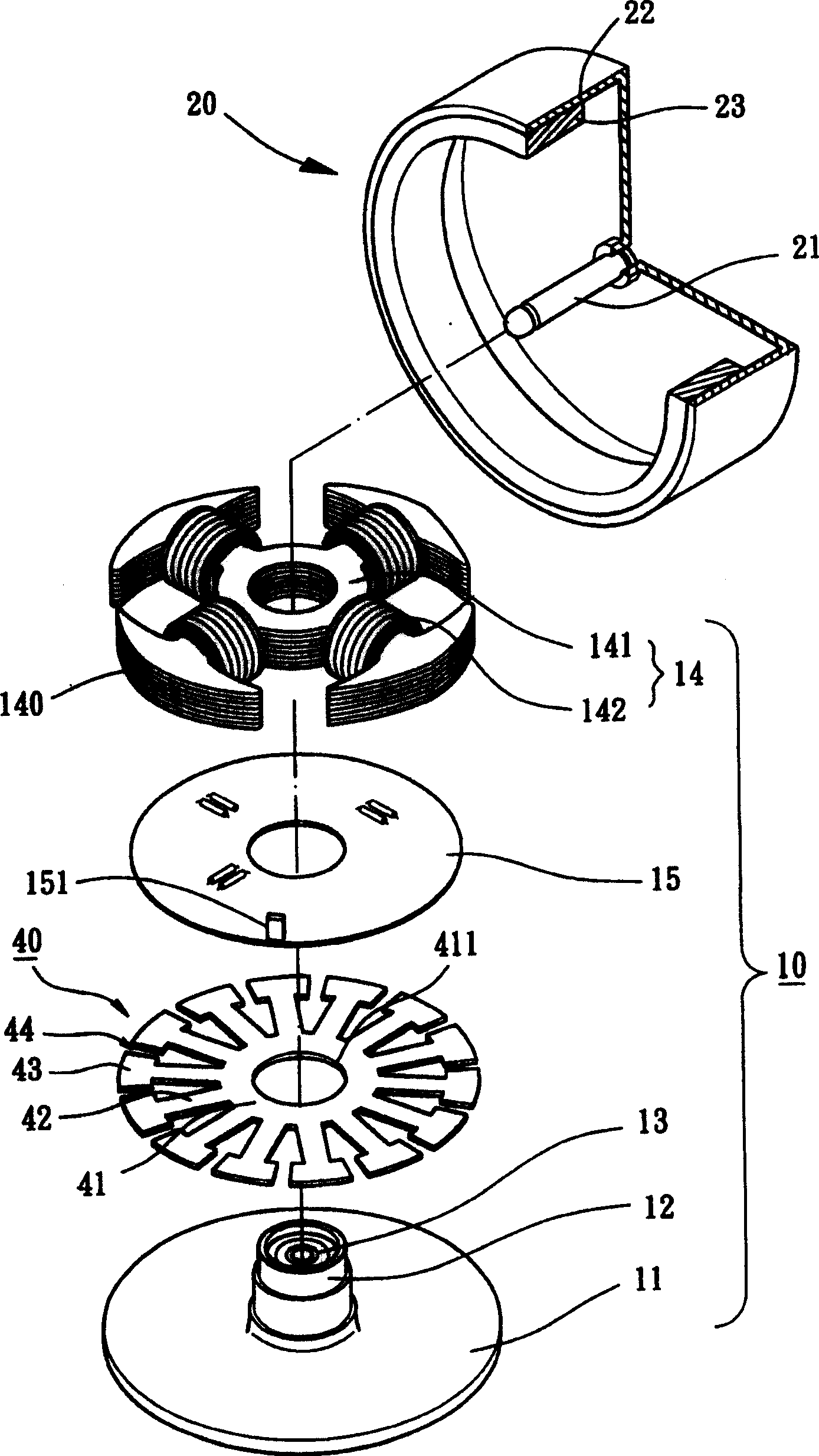

[0043] Please refer to figure 1 As shown, the motor structure of the first embodiment of the present invention includes a fixed part 10, a rotor 20 and a magnetic induction balance piece 30, which can be applied to high-tech motor fields such as cooling fans or optical drive spindle motors, especially small and wireless motors. brushed DC motor field.

[0044] Please refer to figure 1 and figure 2 As shown, the fixing part 10 of the first embodiment of the present invention is provided with a base 11 , a shaft tube 12 , a bearing 13 , a stator assembly 14 and a circuit board 15 . The base 11 is a housing (not shown) that can be combined with a motor. The shaft tube 12 can be selected to be manufactured s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com