Laying off mechanism of bentonite waterproof compound felt processing machine

A composite felt and bentonite technology, used in felting equipment, textiles and papermaking, lamination devices, etc., to prevent dust, avoid excessive friction, and reduce resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

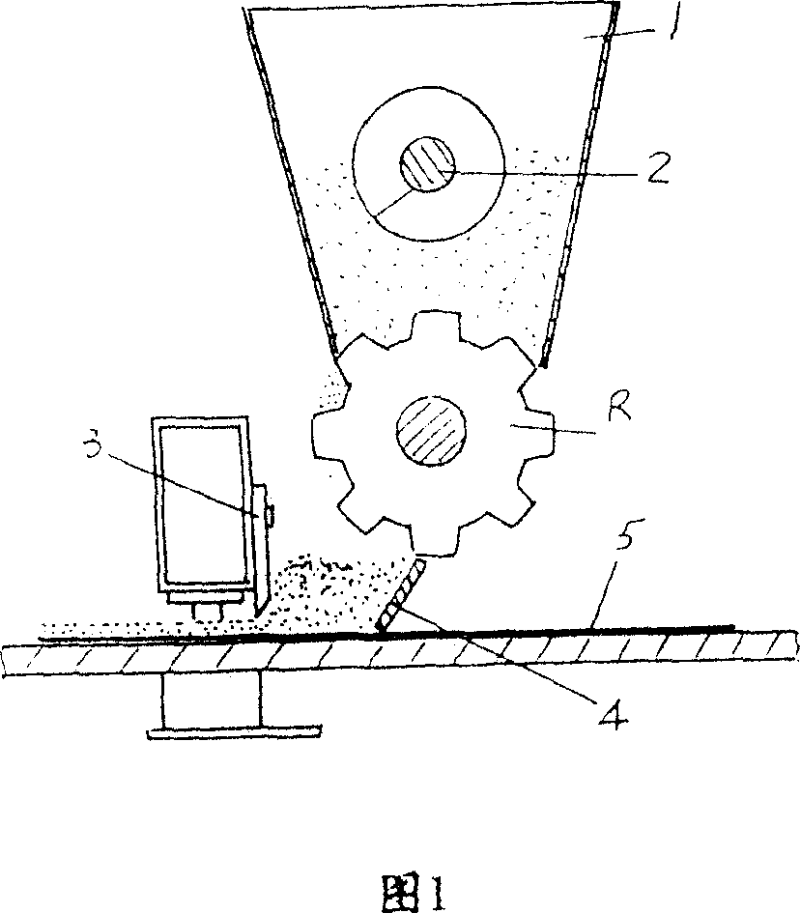

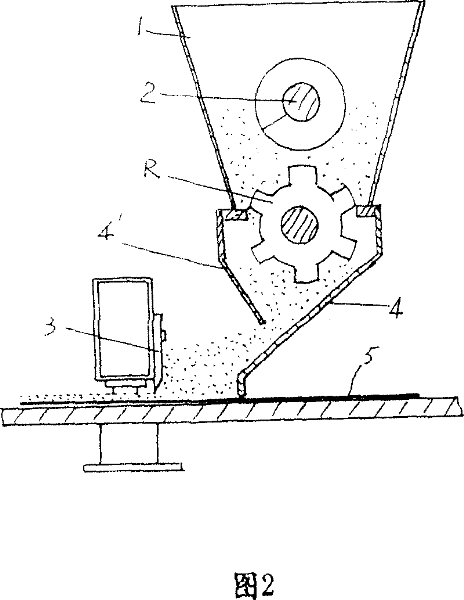

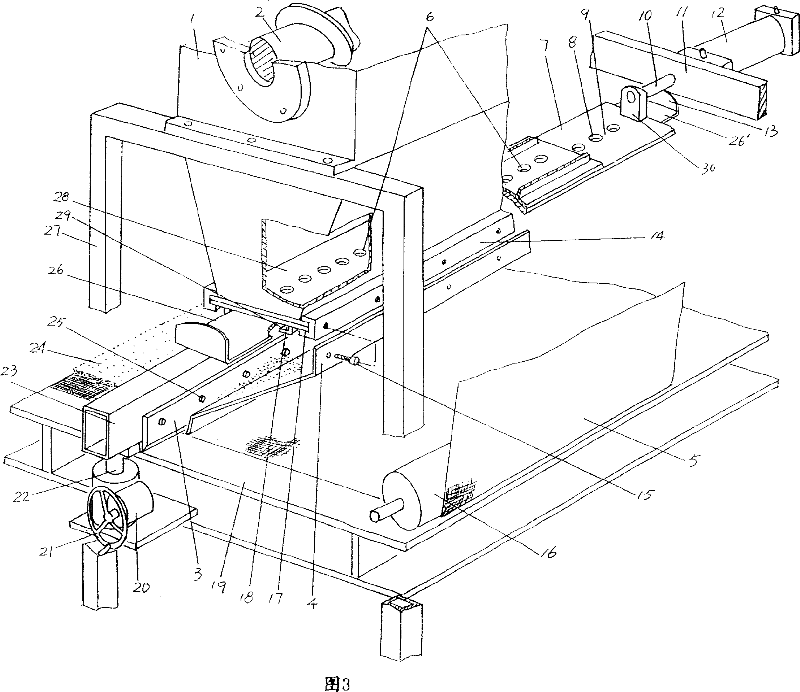

[0017] Please refer to FIG. 3, the hopper 1 is fixed on the frame 27 of the bentonite processing machine, the stirring cage shaft 2 and both ends are pivoted on the bucket wall of the hopper 1, and the stirring cage shaft 2 has a stirring cage or a stirring blade (Fig. (not shown in the figure) is located in the hopper 1, that is, the middle part of the stirring cage shaft 2 is located in the hopper 1. The blade 3 is bolted on the blade beam 23 by bolts 25 in the same way as the prior art, and the two ends of the blade beam 23 are respectively supported on the blade beam adjustment device, and the blade beam adjustment device includes an adjustment screw. Column 22, screw adjustment seat 20, adjustment hand wheel 21, the top of the adjustment stud 22 is fixedly connected with the cross beam 23 of the blade plate, and the lower part is in the screw adjustment seat 20, which is matched with the screw adjustment seat 2, and the screw adjustment The seat 20 is fixed on the frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com