Production process of wire drawing hard alloy die with gradient varying performance

A cemented carbide and production method technology, applied in the direction of wire drawing dies, etc., can solve the problems of low carburizing treatment efficiency, long carburizing treatment time, low reaction activity, etc. The effect of low production cost and energy consumption

Inactive Publication Date: 2007-10-10

ZIGONG CEMENTED CARBIDE CORP +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The solution of the present invention is to address the defects of the background technology such as long carburizing treatment time, simple carburizing agent composition, low reactivity, and low carburizing treatment efficiency, and use Al-containing 2 o 3 , graphite particles and carbonate or / and bicarbonate mixed powder as carburizing agent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0029] Present embodiment adopts the calcium bicarbonate 45wt% that purity is technical grade, and purity is 99.5% Al 2 o 3 40wt% and 15wt% of graphite particles with 99.9% C content and 15wt% mixed powder with an average particle size of 1.0mm were used as carburizing agent;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

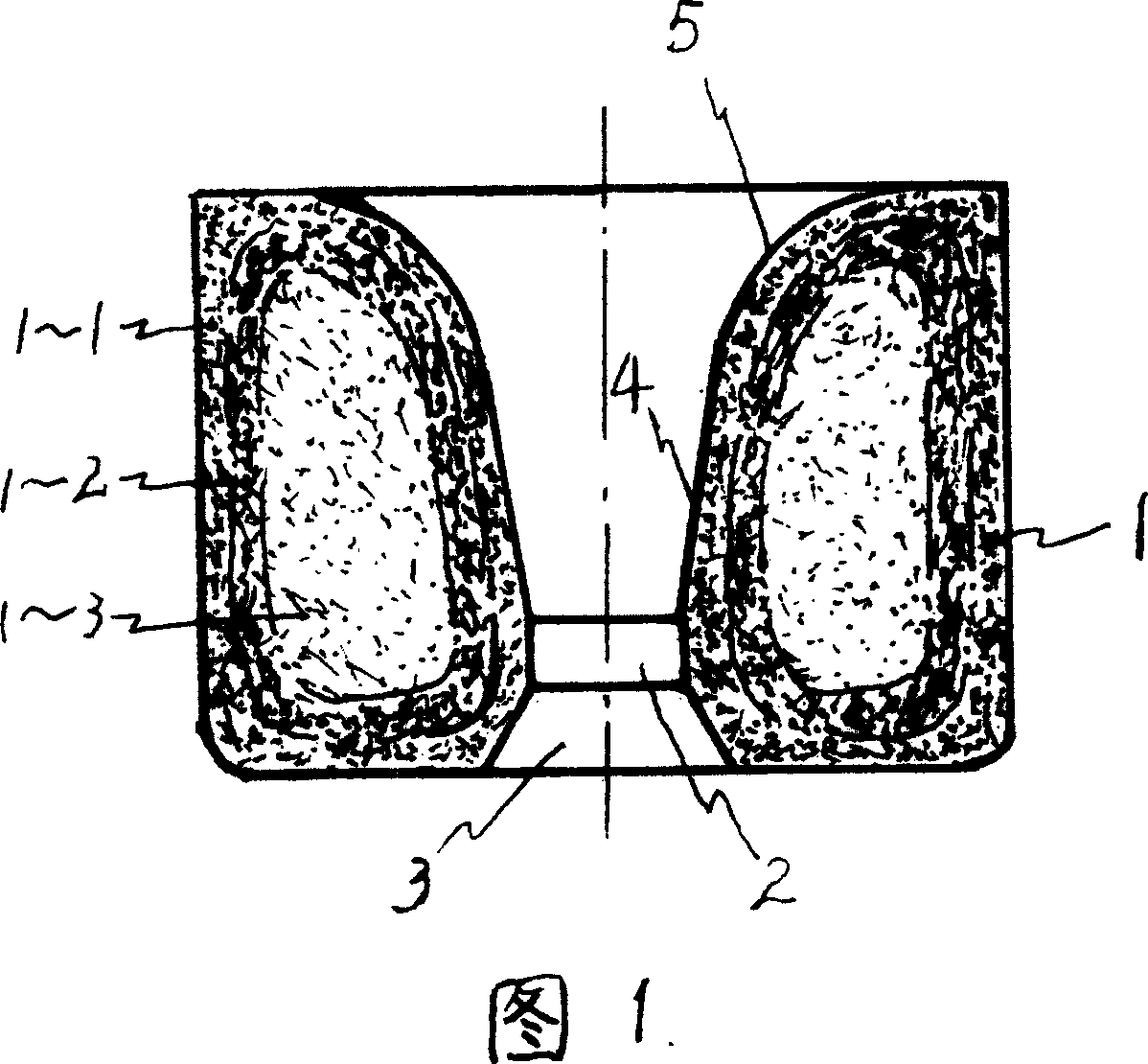

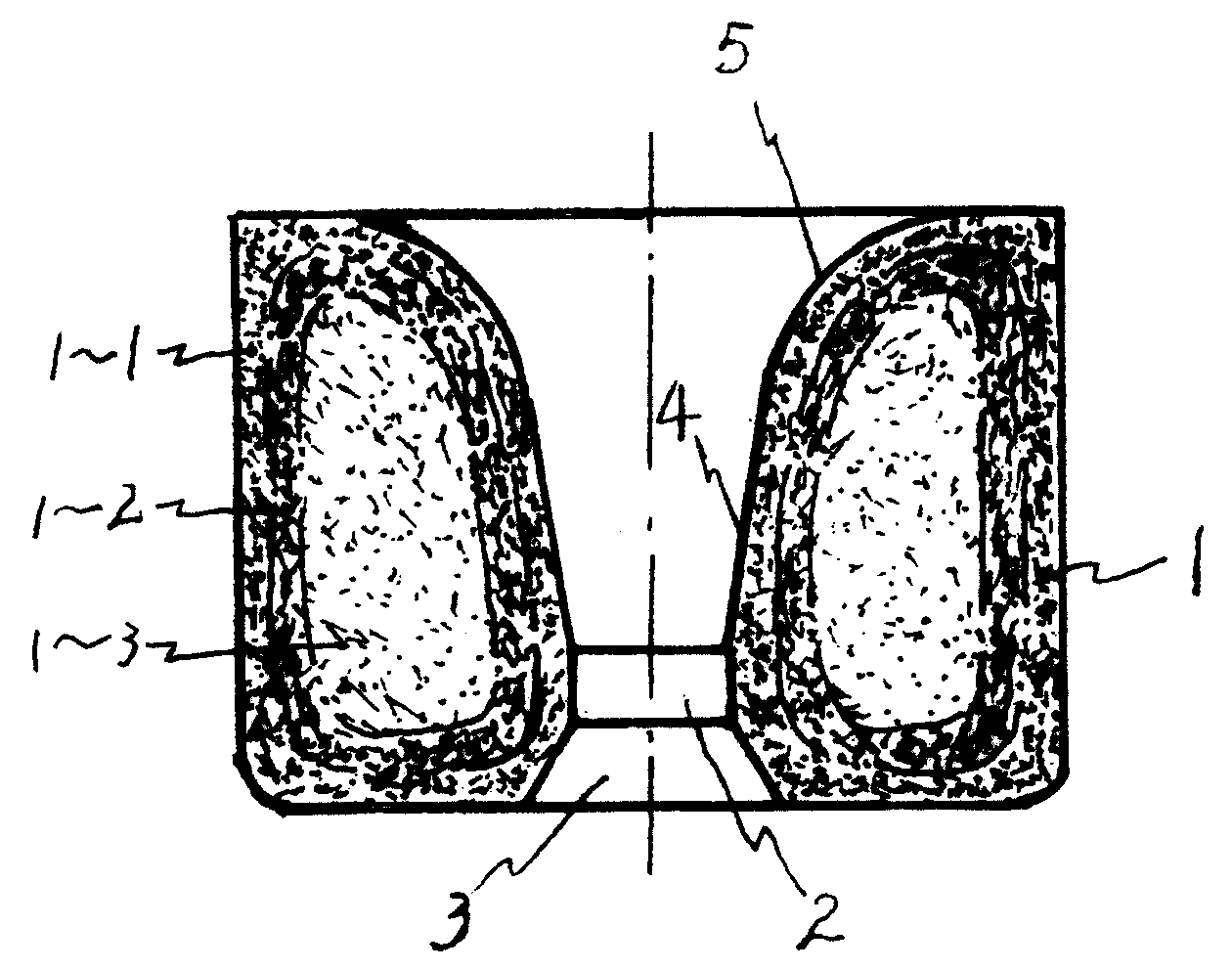

The production process of wire drawing hard alloy die includes compounding material, molding to form, pre-sintering and dewaxing, sintering and carbonization. During the carbonization, the mixture of Al2O3, graphite grain and carbonate and / or bicarbonate in certain proportion is used as carbonizing agent, the carbonate and / or bicarbonate is high temperature decomposed into CO2, CO2 is further reacted with graphite grain into active CO gas capable of entering into liquid phase and reacting to produce WC, and the inward immigration of CO speeds the formation of the gradient structure inside the alloy. The said carbonization procedure has relatively low temperature, short period and relatively thick surface layer without eta phase, and the alloy has obvious gradient adhering phase structure, high comprehensive mechanical performance, high average bending strength and high average hardness.

Description

technical field [0001] The invention belongs to a production method of a cemented carbide wire drawing die in the field of wire drawing die production, in particular to a production method of a cemented carbide wire drawing die in which the mechanical properties of the die body are distributed in a gradient from outside to inside. Background technique [0002] The internal and external mechanical properties and metallographic structure of traditional cemented carbide molds (that is, standard cemented carbide molds) are consistent. This type of mold often has a contradiction between high hardness, wear resistance and toughness that is difficult to reconcile, namely When reducing the content of cobalt (Co) in the alloy to increase its hardness and wear resistance, the toughness of the alloy body will decrease accordingly, otherwise it will affect its hardness and wear resistance. In addition, for cemented carbide wire drawing dies with consistent metallographic and mechanical ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F3/12C23C8/64B21C3/02

Inventor 刘咏张林秋羊建高李芳

Owner ZIGONG CEMENTED CARBIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com