Fluorescent oil film gray scale and thickness modeling method based on neural network

A neural network, BP neural network technology, applied in the field of neural network-based fluorescent oil film grayscale and thickness modeling, can solve the problem of increasing the cost of experiments, greatly affecting the measurement accuracy, and establishing a relationship model between the grayscale and thickness of non-fluorescent oil film, etc. Problems, saving cost and time, convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

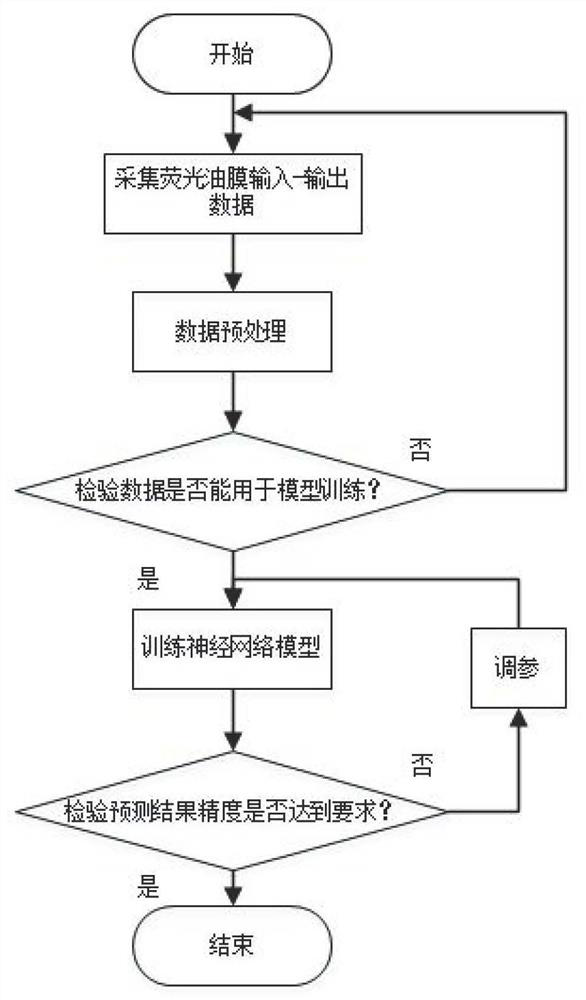

[0050] A neural network-based method for establishing a fluorescent oil film grayscale and thickness model, which is mainly divided into three modules: data acquisition and processing, training BP (back propagation) neural network model, and accuracy inspection. The overall scheme adopts the following technical scheme to realize :

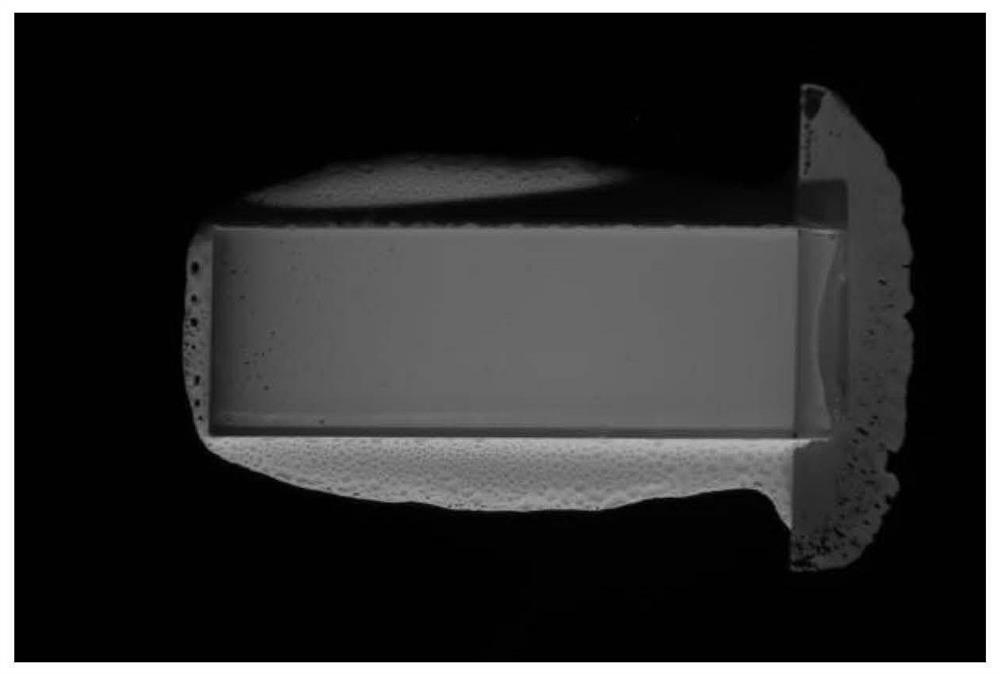

[0051] (1) The data acquisition module collects the grayscale and thickness data of the fluorescent oil film through a reliable data acquisition method. Part of the data is mainly used for the training of the BP (back propagation) neural network, and the other part is used for the accuracy test of the prediction result. Specific steps are as follows:

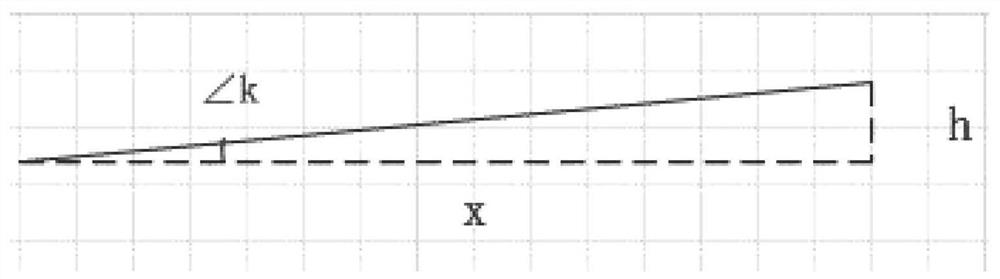

[0052] 1) Use two glass slides with a light transmittance of 95% and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com