Heat carrier and method for the production thereof

A technology of heat conduction and flat tubes, applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchanger types, etc., can solve problems such as difficult processing or forming, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

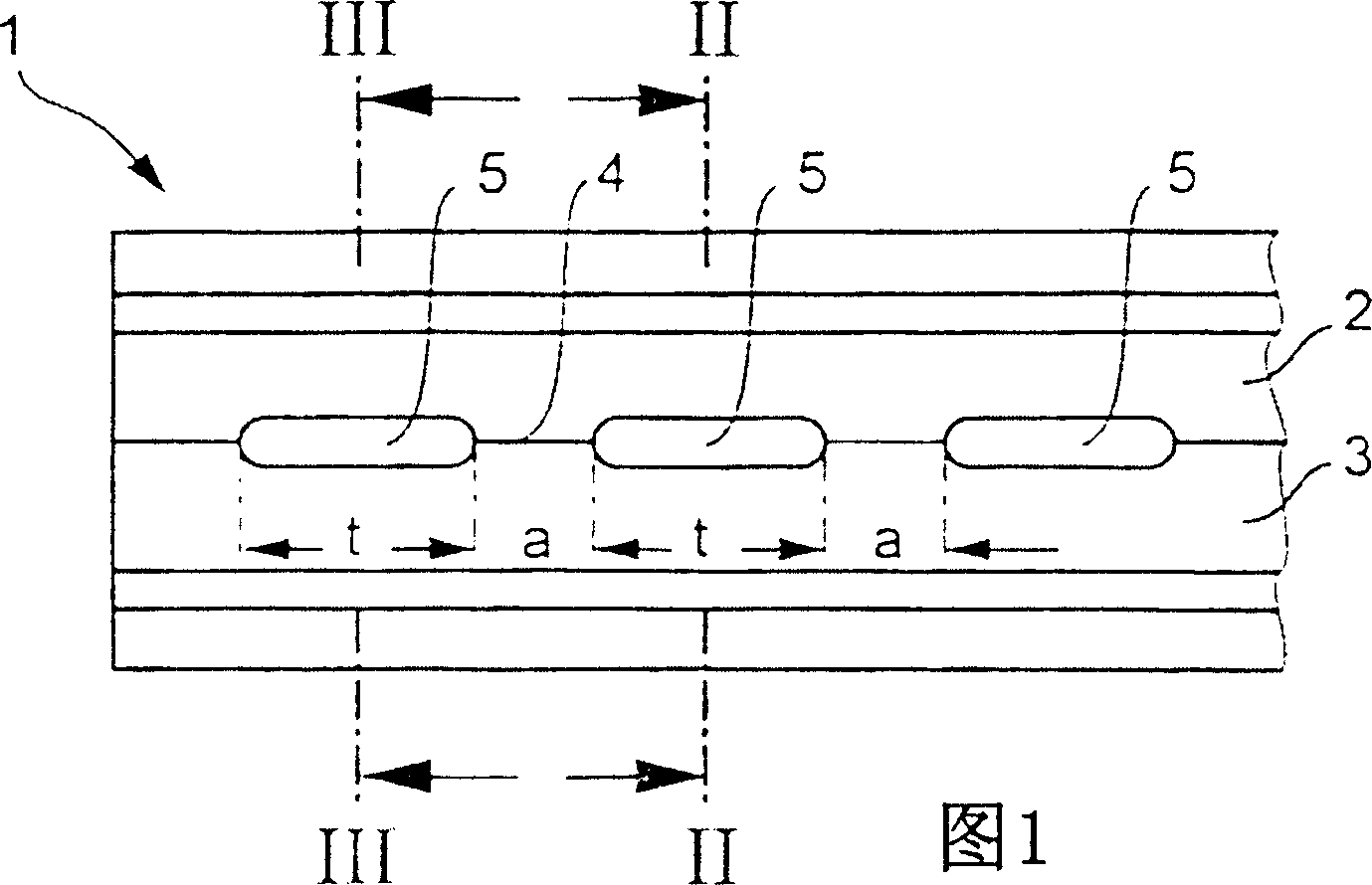

[0018] Fig. 1 is a bottom view of a collector pipe used on a heat exchanger in an automotive CO2-air conditioning system (not shown). The collecting pipe (part) shown in the figure is a notched hollow profile whose edge strips 2 , 3 meet each other at a common seam or parting seam 4 . The seam or parting seam 4 extends in the longitudinal direction, and slot-shaped receiving holes 5 are arranged in this region, the length of which is t, and the distance between the holes is a.

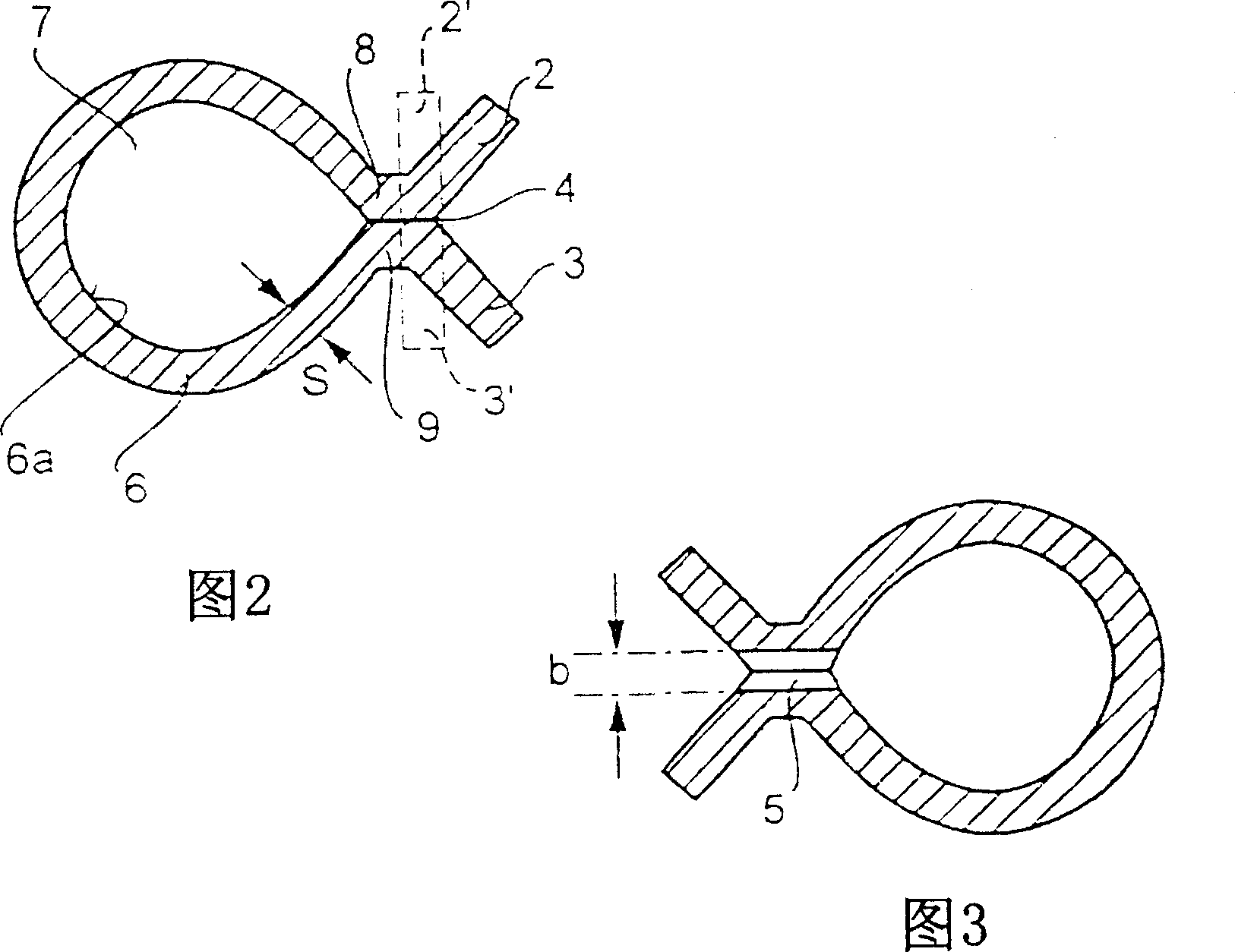

[0019] FIG. 2 shows a section through the collecting pipe 1 , ie along the line II-II in FIG. 1 , that is to say in the region of the seam 4 . The collecting pipe 1 is produced by bending a steel strip 6 of thickness s into a hollow profile 7 , the two projecting sides 8 , 9 of which abut one another and form the joint 4 . The steel strip 6 or the hollow profile 7 continues past the edges 8 , 9 into V-shaped raised edge strips 2 , 3 . Shown in dotted lines are edge strips 2', 3' extending at right an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com