Pipe connector

A technology for pipe joints and connecting parts, applied in the field of pipe joints, can solve the problems of time-consuming, complicated operation, troublesome and other problems, and achieve the effects of ensuring insertability, improving waterproof performance, and simple continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, an embodiment of the present invention will be described with reference to the drawings.

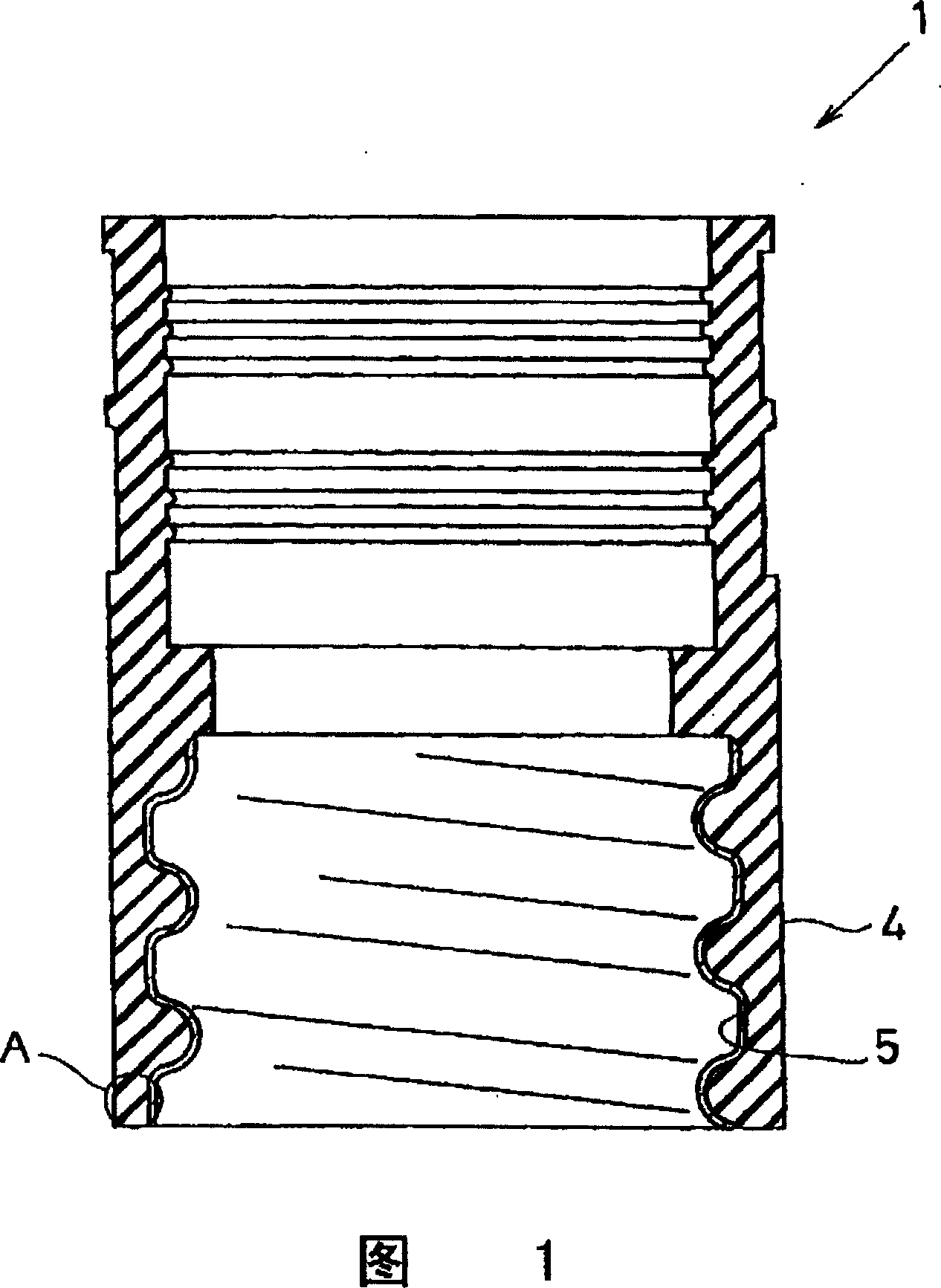

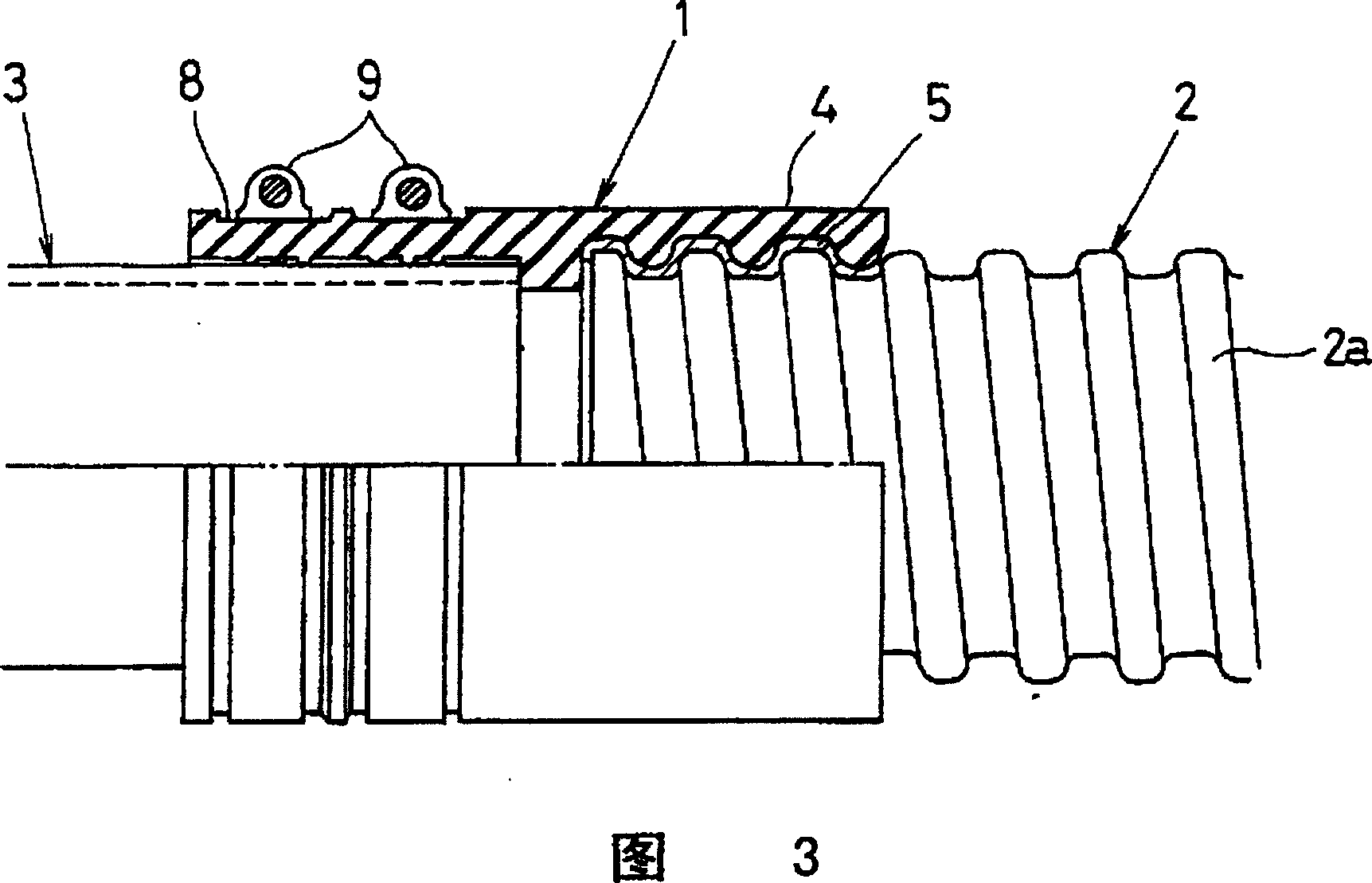

[0022] Fig. 1 is a cross-sectional view of a pipe joint 1, which is used to connect as a pipe body provided with a spiral protrusion 2

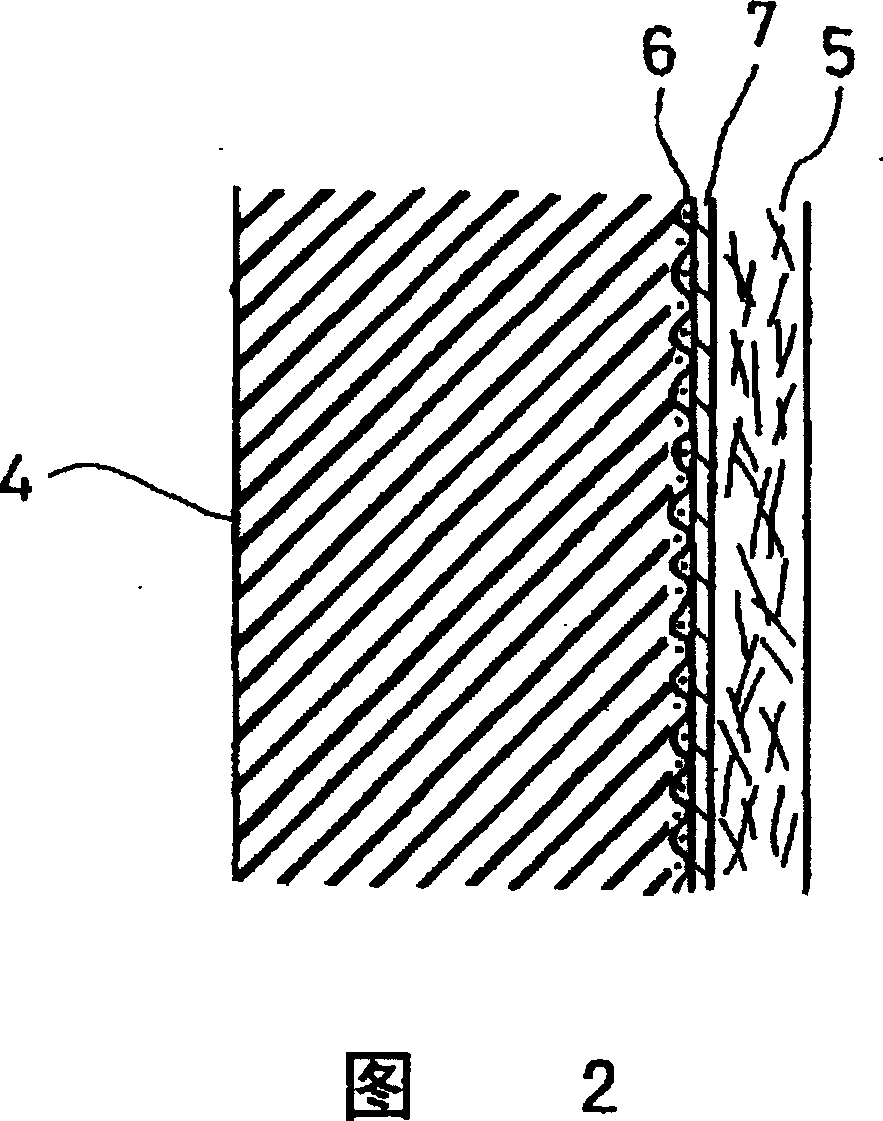

[0023] The synthetic resin corrugated tube 2 of a and the synthetic resin tube 3 without protrusions are made of rubber. However, it may be formed with synthetic rubber or natural rubber, or rubber in which synthetic rubber and natural rubber are mixed together. Further, on the inner surface of the connecting portion 4 for connecting the synthetic resin corrugated tube 2, an inflatable body 5 that swells by absorbing water is integrally formed.

[0024] The expansion body 5 is composed of a non-woven fabric, a mixture of a superabsorbent resin and a thermoplastic resin. Since the forming temperature is relatively high, fibers with good heat resistance such as polyethylene terephthalate (PET) should be used for the above-mentioned nonwoven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com