A kind of ethylene glycol bis (propionitrile) ether continuous purification method and device

A technology of ethylene glycol bisulfite purification method, which is applied in chemical instruments and methods, carboxylic acid nitrile purification/separation, separation methods and other directions, can solve the problems of poor product quality stability, difficult control of reaction conditions, and increased separation difficulty, etc. To achieve better separation effect, continuous production operation, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

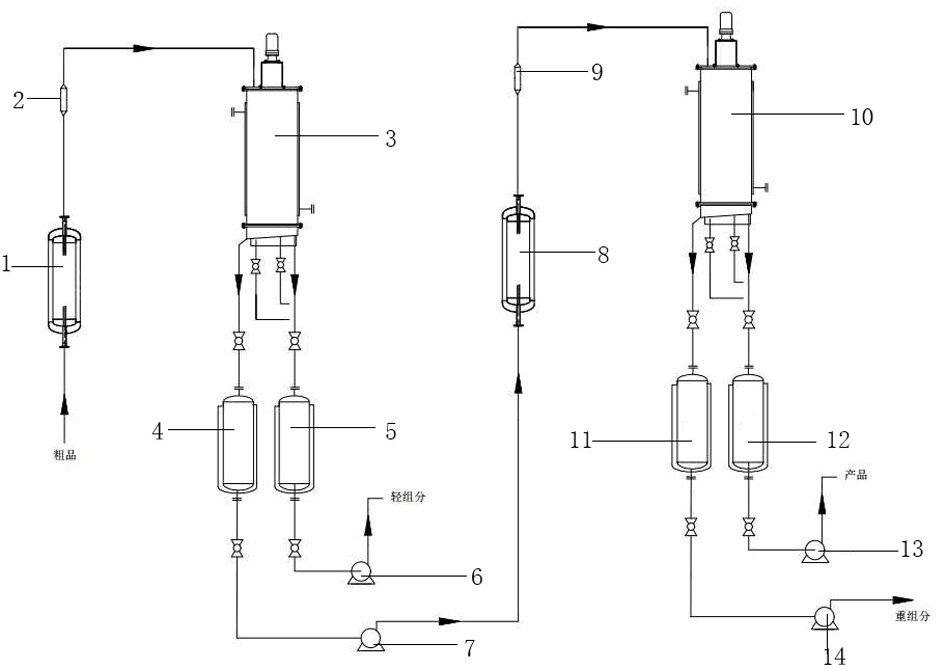

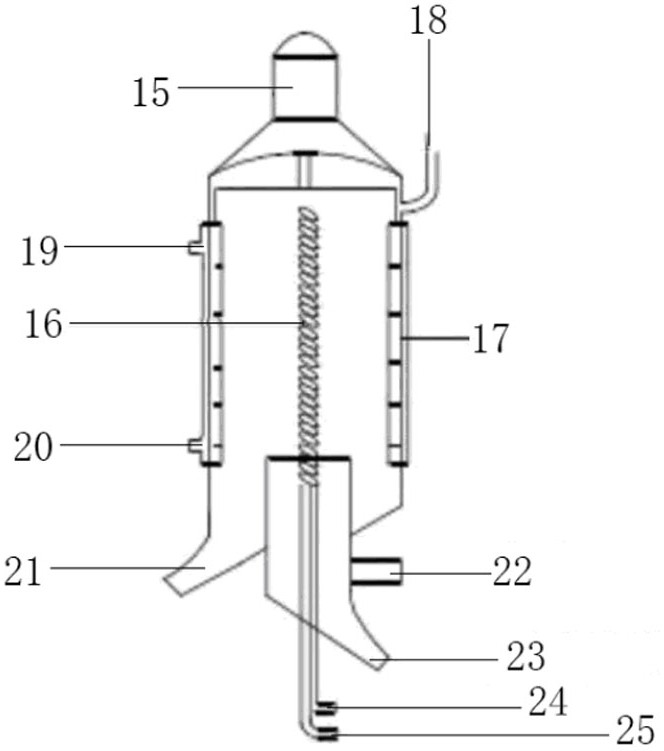

[0021] like Figure 1-2 As shown, the embodiment of the present invention provides a continuous purification method for ethylene glycol bis(propionitrile) ether, comprising the following steps:

[0022] S1. Device construction: Install preheater one 1, temperature sensor one 2, evaporator one 3, buffer tank one 4, buffer tank two 5, pump one 6, pump two 7, preheater two 8 at the designated position , temperature sensor two 9, evaporator two 10, buffer tank three 11, buffer tank four 12, pump three 13 and pump four 14, and complete the connection between the devices;

[0023] S2. System debugging: set the temperature and pressure for preheater one 1, temperature sensor one 2, evaporator one 3, buffer tank one 4, buffer tank two 5, pump one 6 and pump two 7; Set the temperature and pressure of the device two 8, the temperature sensor two 9, the evaporator two 10, the buffer tank three 11, the buffer tank four 12, the pump three 13 and the pump four 14;

[0024] S3, light compo...

Embodiment 2

[0032] like Figure 1-2 As shown, the embodiment of the present invention provides a continuous purification method of ethylene glycol bis(propionitrile) ether, comprising the following steps, using ethylene glycol and acrylonitrile as raw materials to carry out a catalytic reaction to obtain 500 g of a crude product with a purity of 94.5%, for subsequent use, in Install preheater one 1, temperature sensor one 2, evaporator one 3, buffer tank one 4, buffer tank two 5, pump one 6, pump two 7, preheater two 8, temperature sensor two 9, After the evaporator two 10, the buffer tank three 11, the buffer tank four 12, the pump three 13 and the pump four 14, and the connection between each device is completed, the system pressure of the debugging and delighting process is 10KPa, and the temperature is 200 ℃, the system pressure of the de-heavy component process is 1KPa, and the temperature is 190℃. After the system reaches the set value of each parameter, the crude product is transpo...

Embodiment 3

[0034] like Figure 1-2 As shown, the embodiment of the present invention provides a continuous purification method for ethylene glycol bis(propionitrile) ether, which includes the following steps, using ethylene glycol and acrylonitrile as raw materials to carry out catalytic reaction to obtain 500 g of a crude product with a purity of 94.3%, for use, in Install preheater one 1, temperature sensor one 2, evaporator one 3, buffer tank one 4, buffer tank two 5, pump one 6, pump two 7, preheater two 8, temperature sensor two 9, After the evaporator two 10, the buffer tank three 11, the buffer tank four 12, the pump three 13 and the pump four 14, and the connection between each device is completed, the system pressure of the debugging and light component removal process is 5KPa, and the temperature is 170 ℃, the system pressure of the de-heavy component process is 500Pa, and the temperature is 180℃. After the system reaches the set value of each parameter, the crude product is tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com