Linkage displacement bidirectional rebar hoop bending machine

A two-way steel bar and hoop bending machine technology, which is applied in the field of construction equipment, can solve problems such as positioning structure coordination and complex hydraulic control systems, and achieve the effects of continuous operation, high degree of automation, and simplified hydraulic control circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

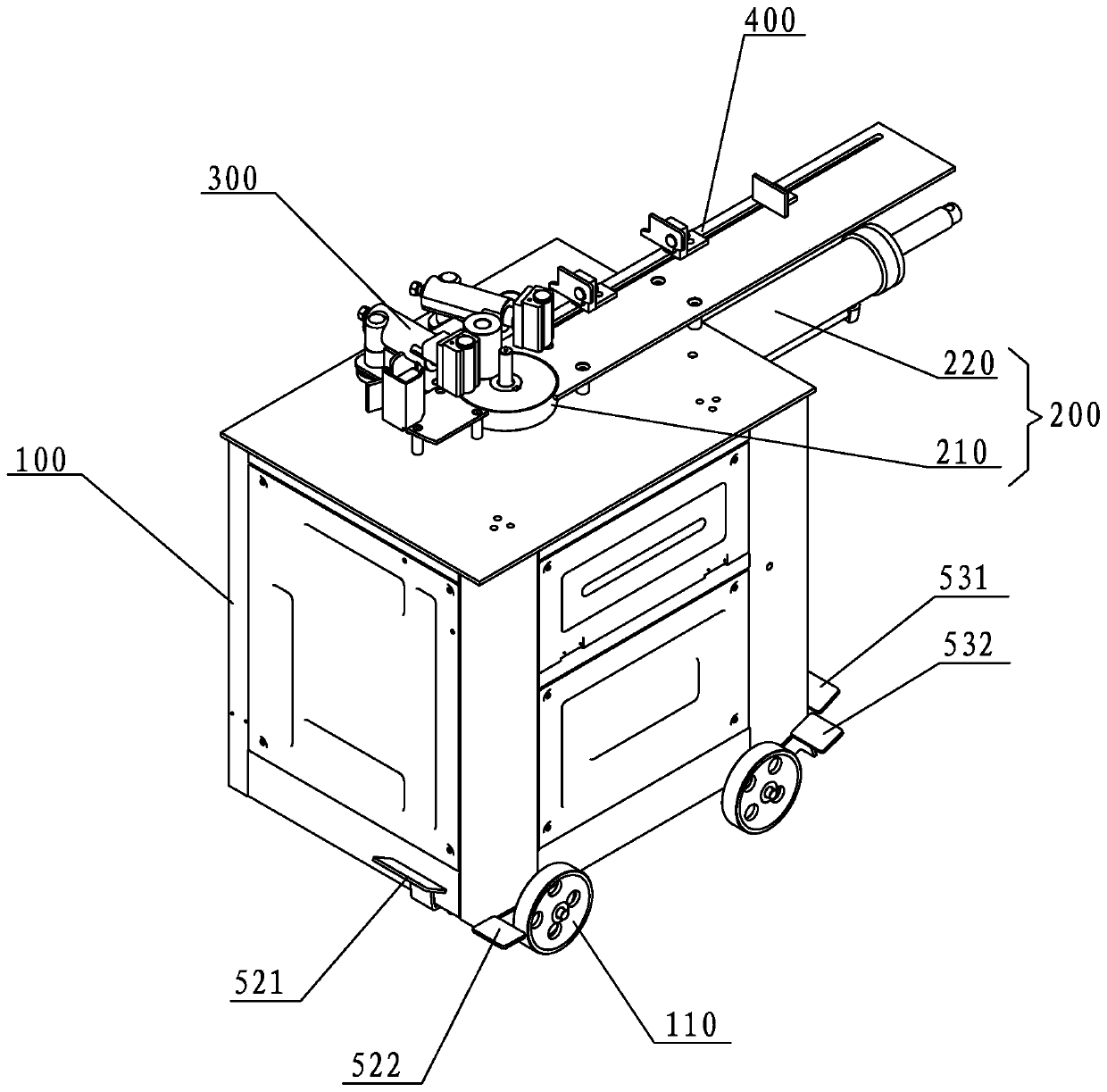

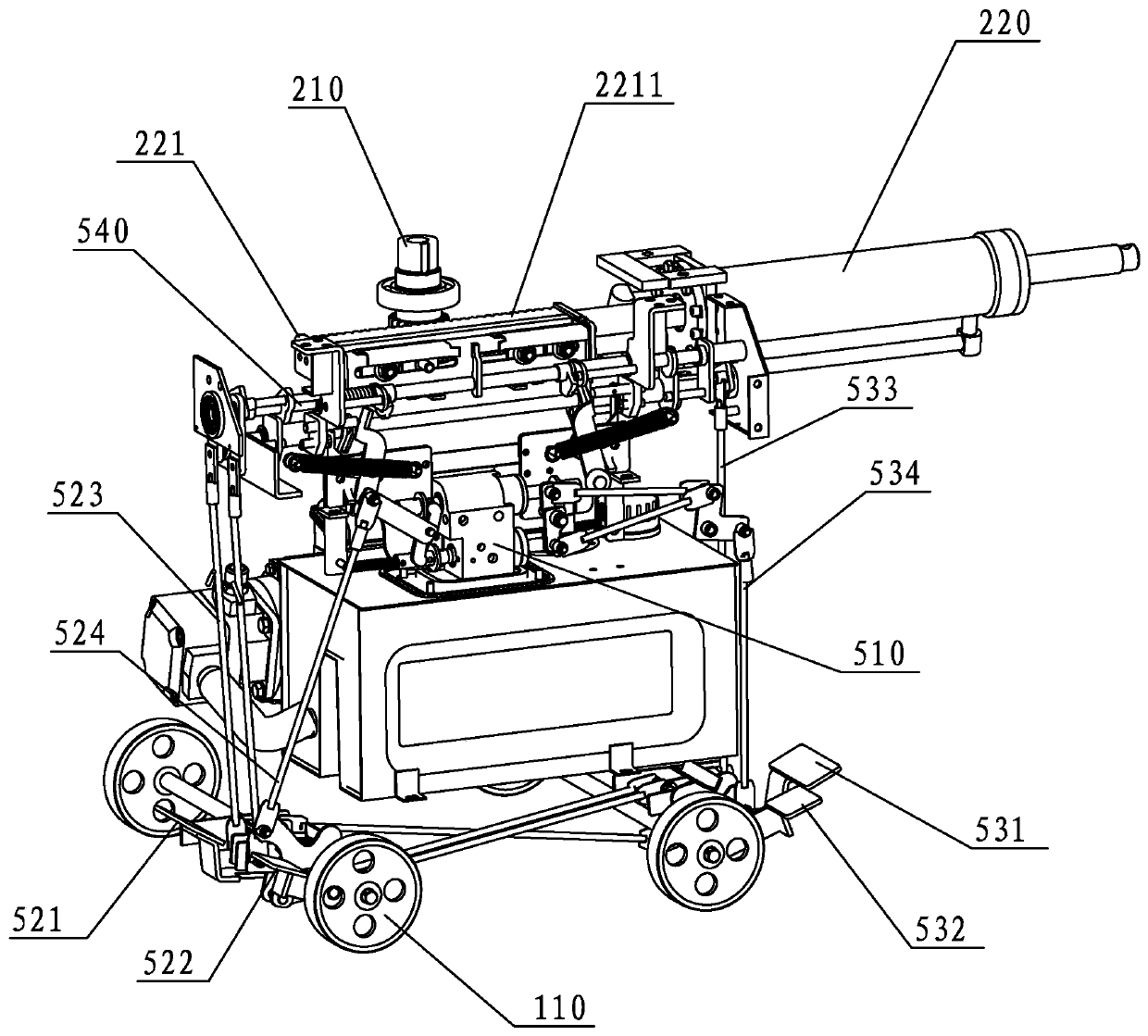

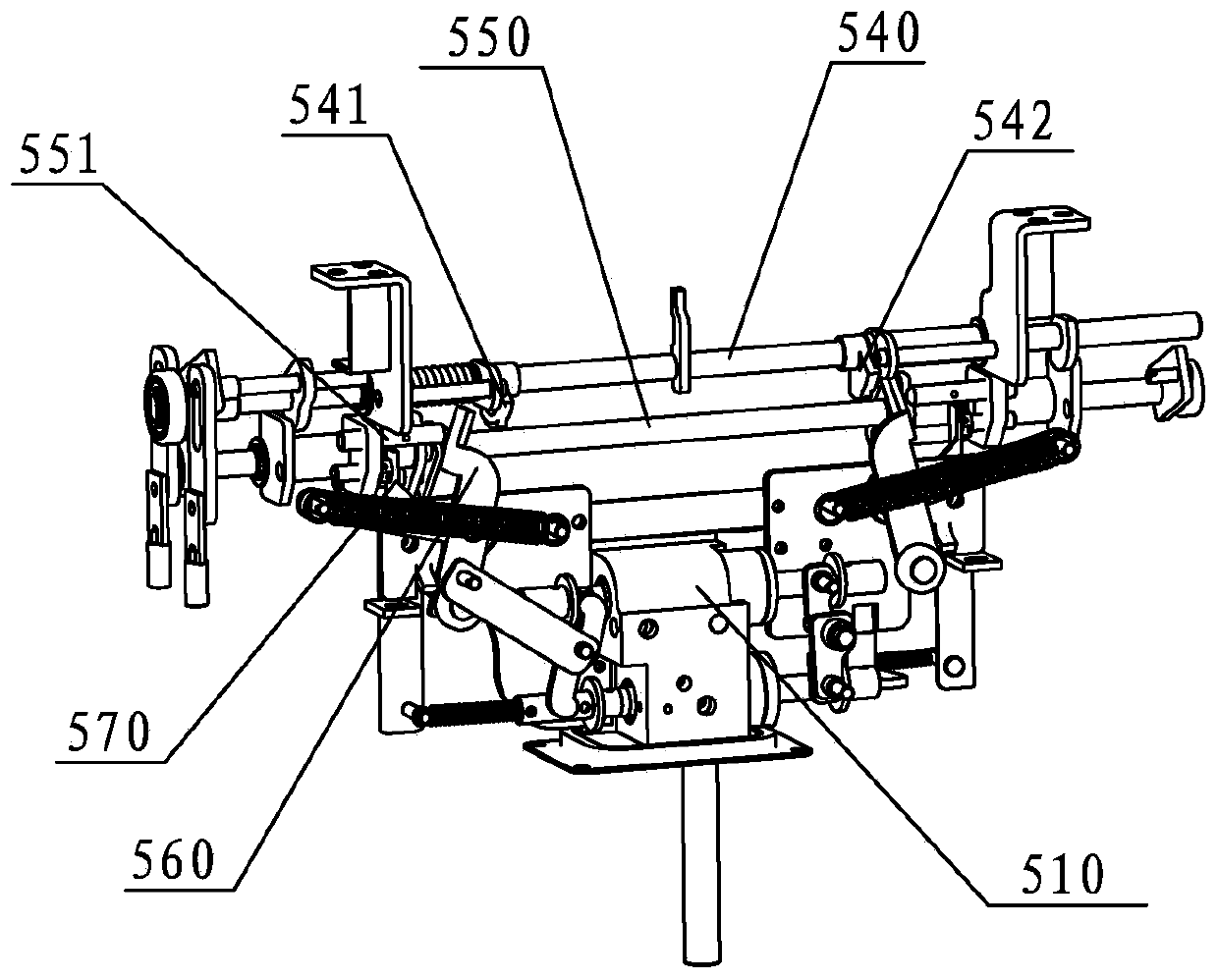

[0047] refer to Figure 1 to Figure 11 , a preferred embodiment provided by the present invention, linkage displacement two-way steel bar hoop bending machine, includes a frame 100, the frame 100 is provided with an oil tank, a two-way bending mechanism 200, and the two-way bending mechanism 200 includes a bending The turntable 210 and the power member 220, the power member 220 is preferably a hydraulic cylinder with a forward stroke and a reverse stroke. The bending turntable 210 is rotatably arranged on the frame 100, and the bending turntable 210 is provided with a center pin and a bending pin, and the bending pin rotates around the center pin. Preferably, the center pin can The telescoping is set on the bending turntable 210 . A drive gear is also arranged below the bending turntable 210 . The piston rod of the power part 220 is connected with a travel bracket 221, and the travel bracket 221 is provided with a drive rack 2211 that engages with the drive gear and drives t...

Embodiment 2

[0056] refer to Figure 12 , Figure 13 , the present invention also provides a second implementation of the linkage displacement pin plate 300 . In the first embodiment, the linked displacement pin plate 300 is displaced through rotation, so as to approach or move away from the bending turntable 210 . In this embodiment, the frame 100 is provided with a bar-shaped guide groove 350, and the forward pin stop plate 310 and the reverse pin stop plate 320 are installed on the guide slot 350 and can translate along the guide slot 350. . Such as Figure 12 As shown, when the steel bar is bent in the forward direction, the forward stopper plate 310 moves close to the bending turntable 210, and the reverse stopper plate 320 moves away from the bending turntable 210; otherwise, the forward stopper plate 310 moves away from the bending turntable 210, reverse The stop pin plate 320 is close to the bending turntable 210, such as Figure 13 shown. Preferably, the forward pin stop pla...

Embodiment 3

[0058] The present invention also provides a third embodiment of the linkage displacement stop plate. The forward pin stop plate and the reverse pin pin plate can also be arranged on the frame in a lifting manner. When the bending turntable bends the steel bar forward, the forward pin stop plate rises to match the center pin shaft and the bending pin shaft pair. When the steel bar is positioned, the reverse baffle plate descends, and when the bending turntable reversely bends the steel bar, the reverse baffle plate rises to coordinate with the central pin shaft and the bending pin shaft to position the reinforcement, and the forward baffle plate descends. Except that the movement mode of the linkage displacement baffle plate is different, other mechanisms of the linkage displacement two-way steel bar bending machine provided by this embodiment are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com