Method for selective leaching separation of cobalt, nickel and molybdenum from high grade cobalt-nickel-molybdenum waste material

A high-grade and selective technology, applied in the direction of improving process efficiency, can solve problems such as unreported, and achieve the effect of obvious effect, simple and continuous operation, great social benefit and economic benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

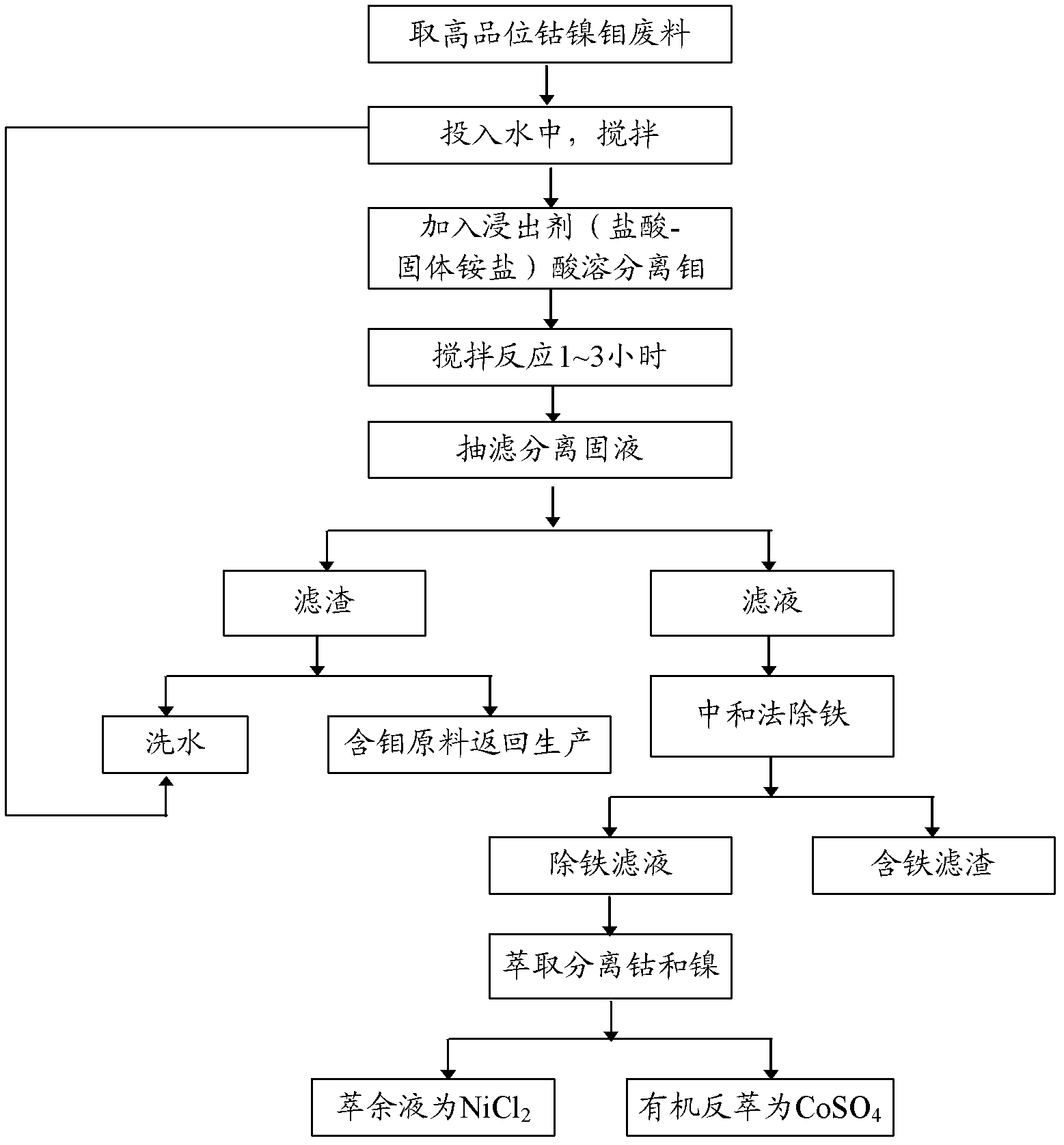

[0033] A method for selectively leaching and separating cobalt, nickel and molybdenum from high-grade cobalt, nickel and molybdenum waste materials, comprising the following steps:

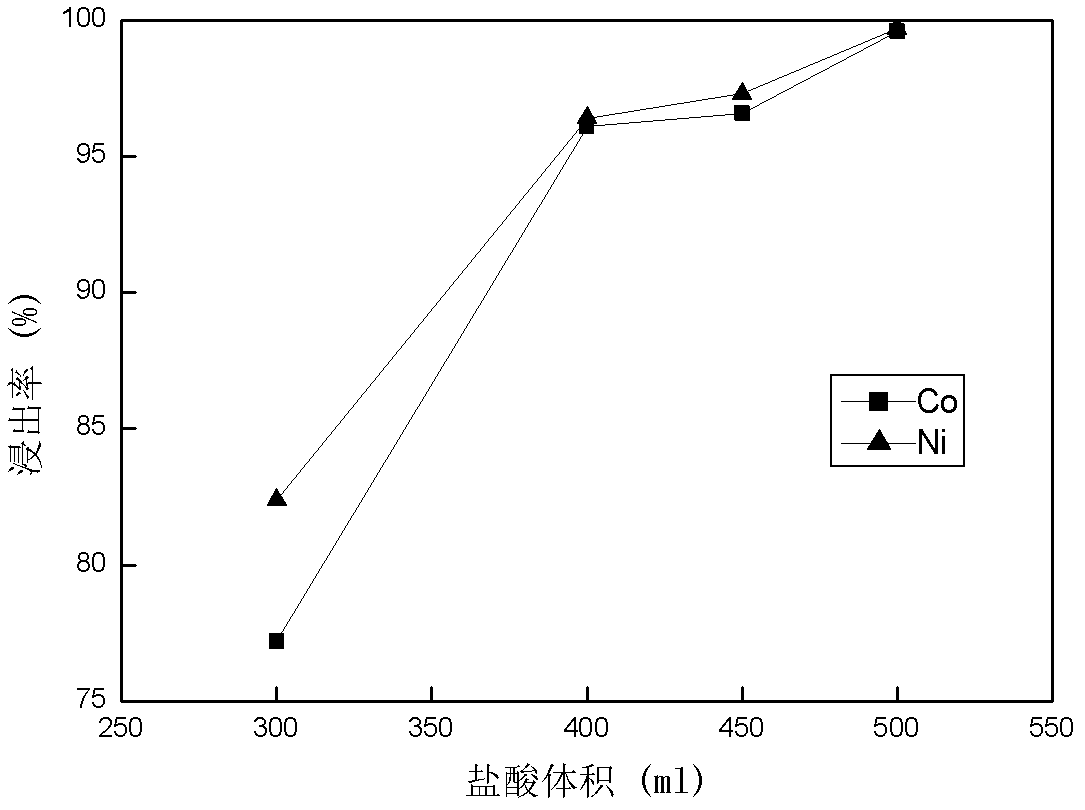

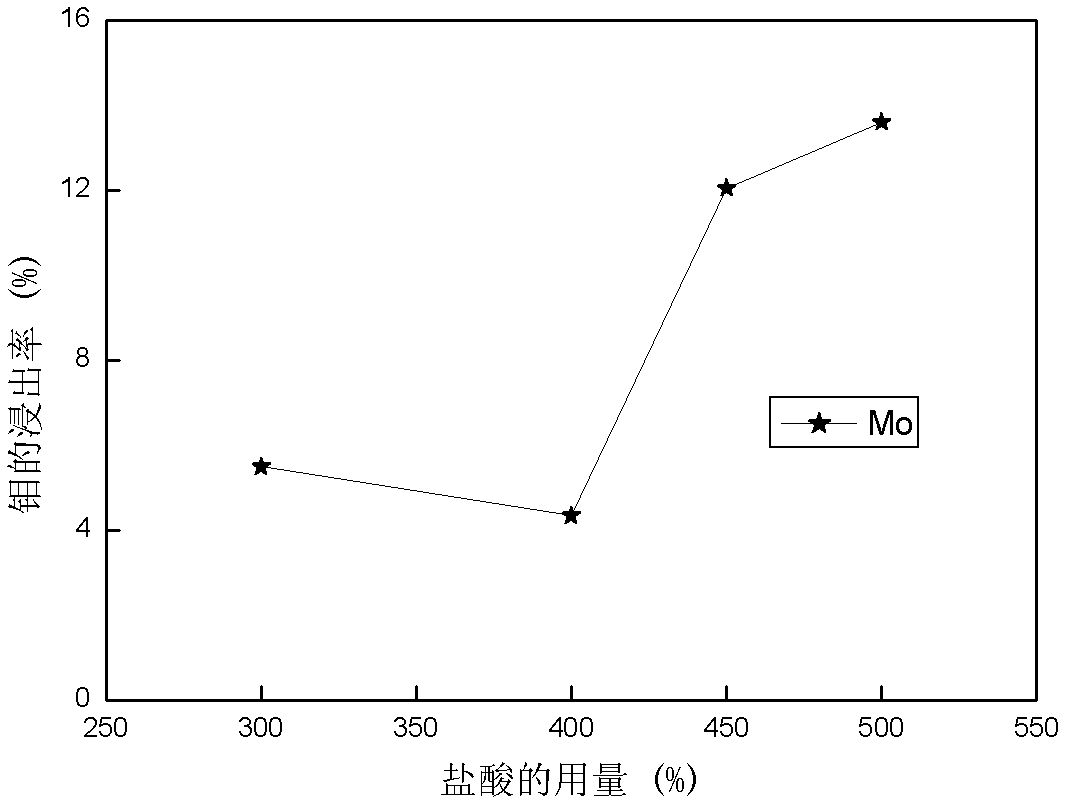

[0034] (1) Separation of molybdenum by acid-soluble method: get 100g of high-grade cobalt-nickel-molybdenum waste (from waste catalysts in the petrochemical industry, the metal content is cobalt: 24.53%, nickel: 19.1% by percentage of the total mass of cobalt-nickel-molybdenum waste , molybdenum: 10.8% and iron: 18.32%), be 1: 10 drop into water by solid-liquid ratio, stir, slowly add the concentrated hydrochloric acid that concentration is 12mol / L and ammonium nitrate carry out acid dissolution, the liquid-solid ratio of hydrochloric acid and ammonium nitrate The ratio was 1.5mL:1g, and the reaction was stirred at 85°C for 2 hours. Suction filtration, separation of solid and liquid, to obtain 820mL cobalt concentration of 26.5g / L, nickel concentration of 22.61g / L, molybdenum concentration of 445....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com