Butterfly valve

A technology of rotating baffles and throttle valves, applied in valve devices, lift valves, valve details, etc., can solve the problems of unsealed seals, uneven use of rubber seals, etc., and achieve the effect of simple assembly and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

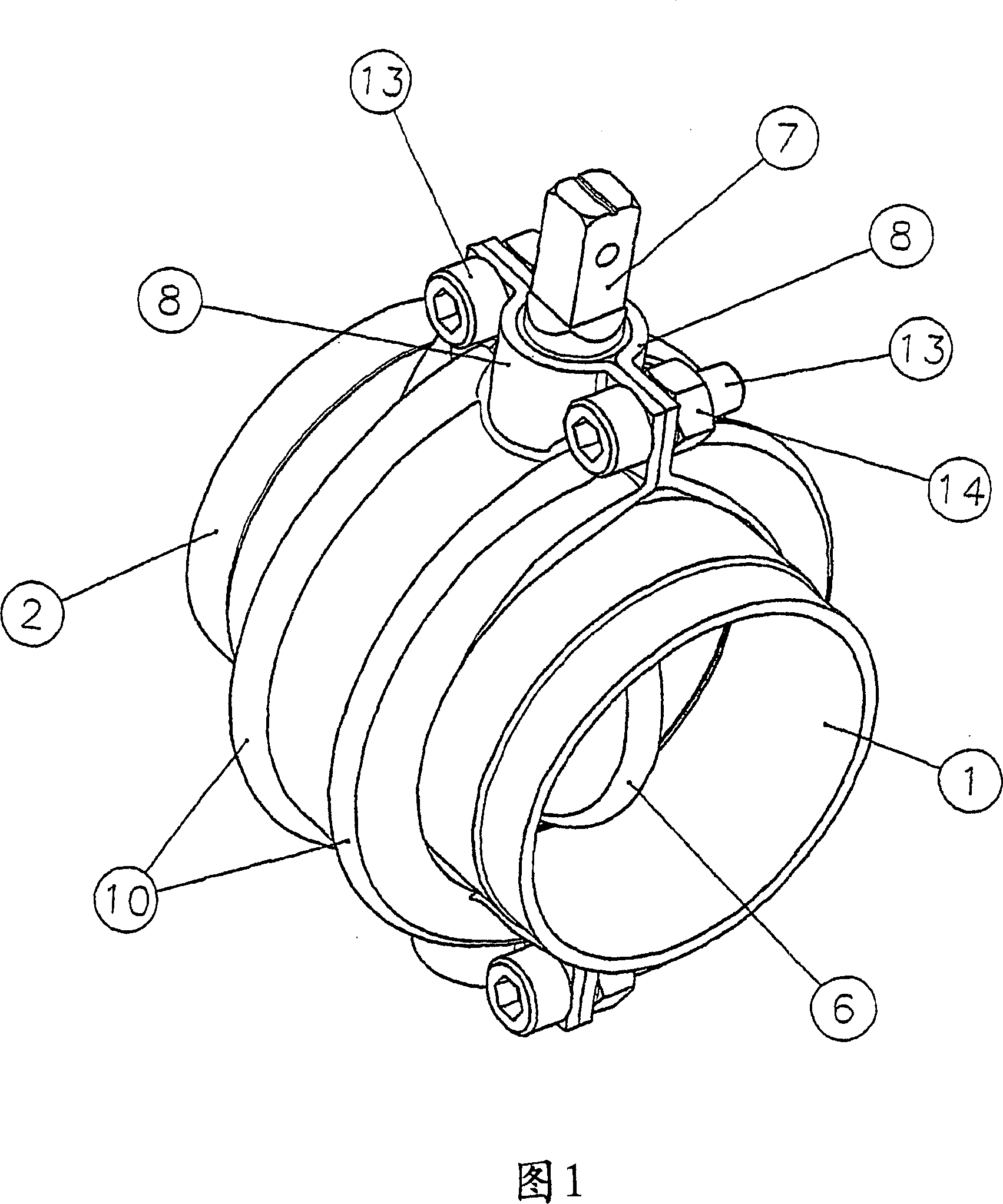

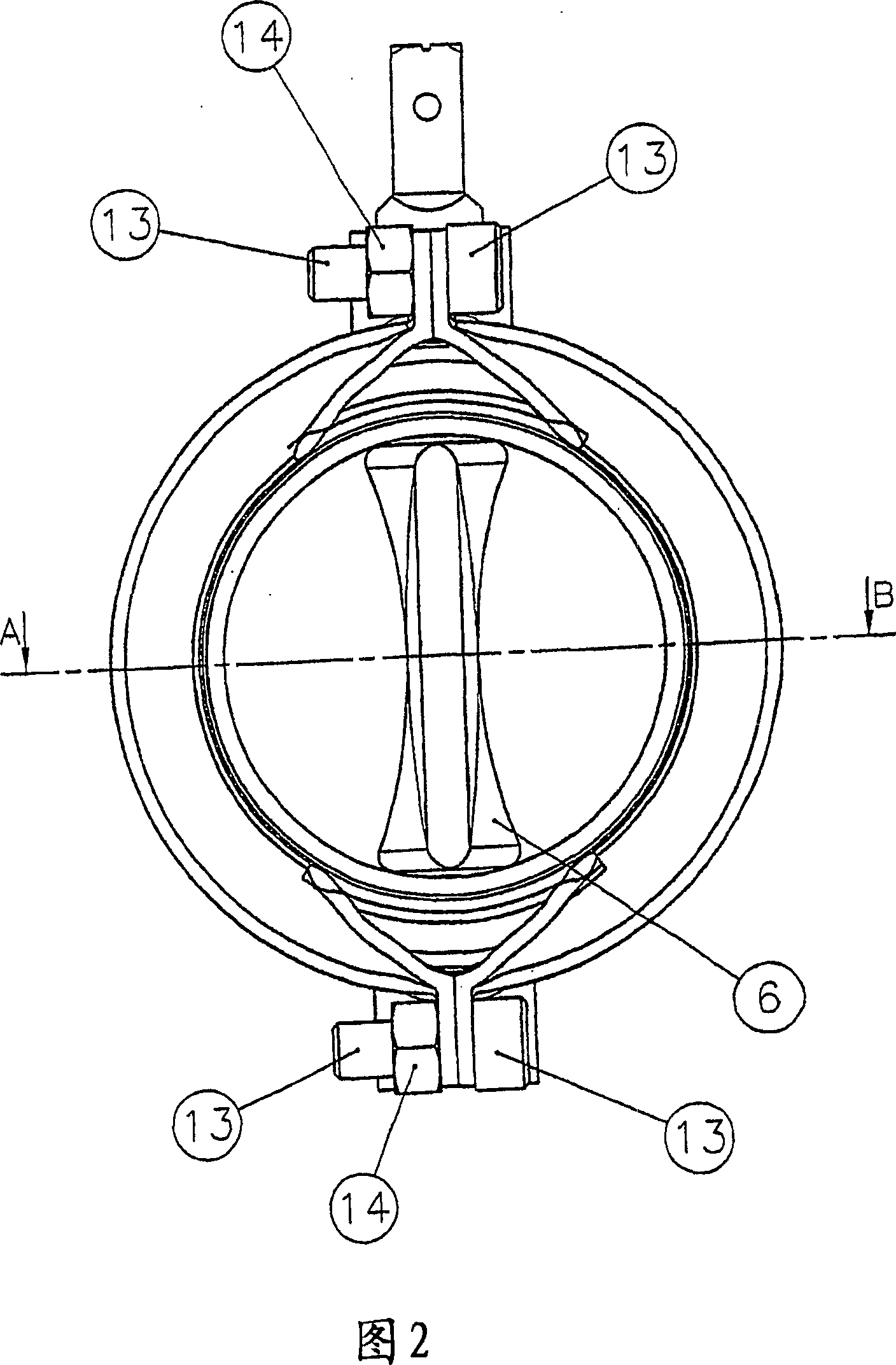

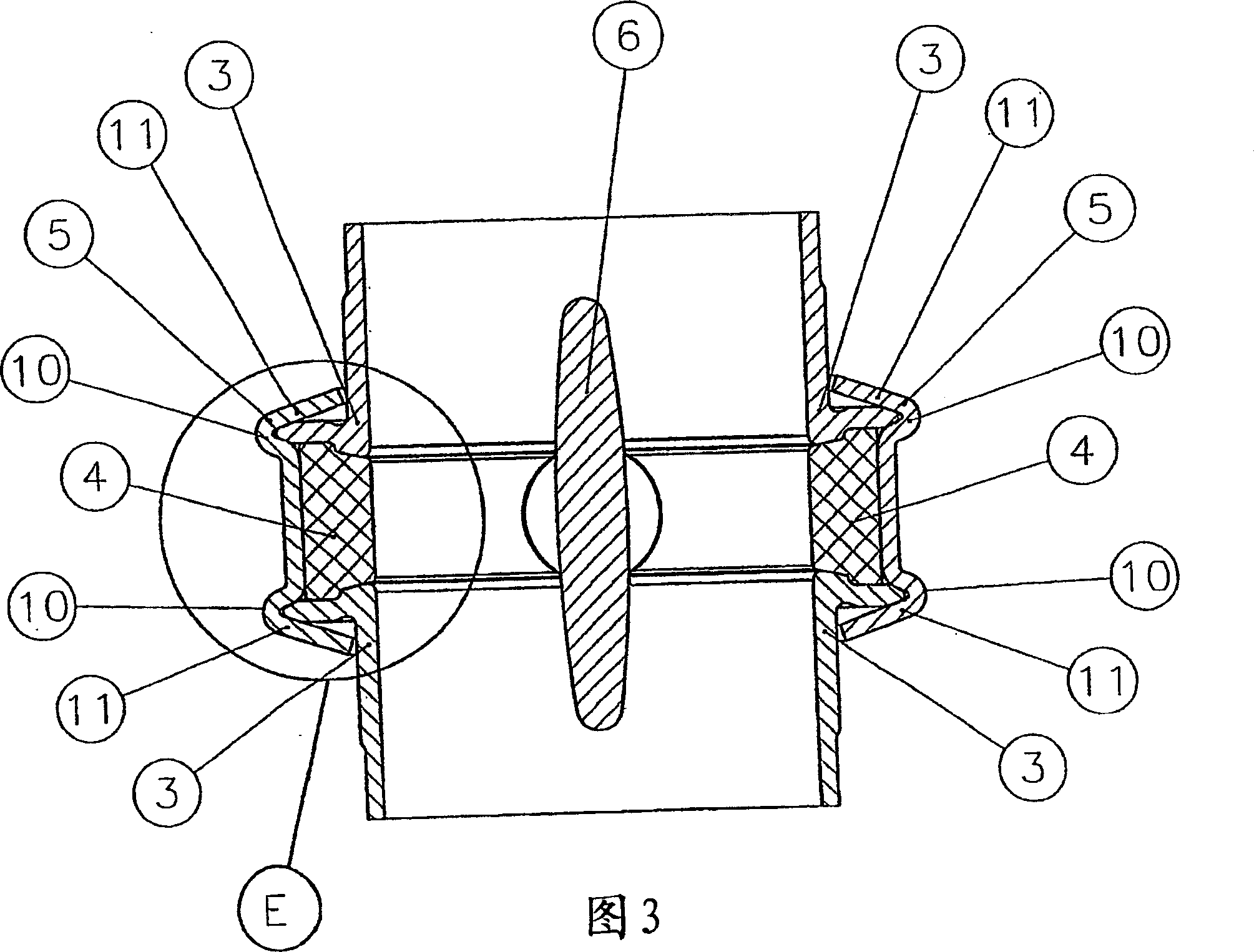

[0025] 1 and 4 show a general view of a rotary flap throttle valve according to the invention, viewed obliquely from above or from the side. As can be seen in the drawing, the valve is formed from a valve inlet part 1 and a valve outlet part 2 . The valve inlet part 1 and the valve outlet part 2 are each provided with a flange 3 , the outer surfaces 15 of which are pressed axially onto the rubber seal 4 via the clamping halves 5 . The rubber seal 4 rests on the valve disk 6 . The valve disk 6 is mounted rotatably via a valve disk rod 7 on a bushing 9 which is inserted into an annular receptacle 8 of the clamping half 5 .

[0026] As can be seen from FIGS. 3 and 1 , the clamping halves 5 are each formed with two annular recesses 10 concentric with the mounting seat of the flange 3 . The recess 10 is beveled at an edge 11 . The flange 3 has a conical taper 12 outwardly. The flange 3 is rigidly connected to the clamping half 5 at its inner and outer contact surfaces 16a and 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap