Device and method for compression moulding of plastic articles

A molding and equipment technology, which is applied in the field of parison molding, can solve problems such as equipment performance limitations, and achieve the effect of accelerating the molding cycle and reducing the closing and opening strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

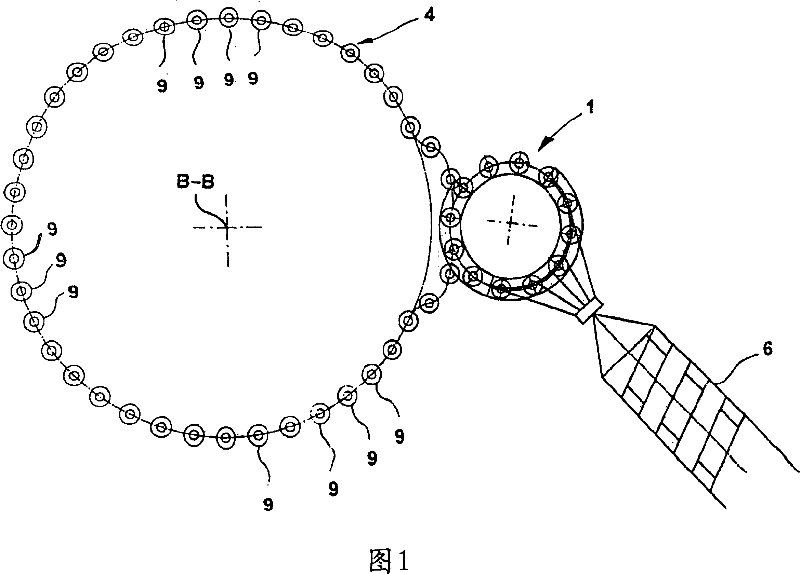

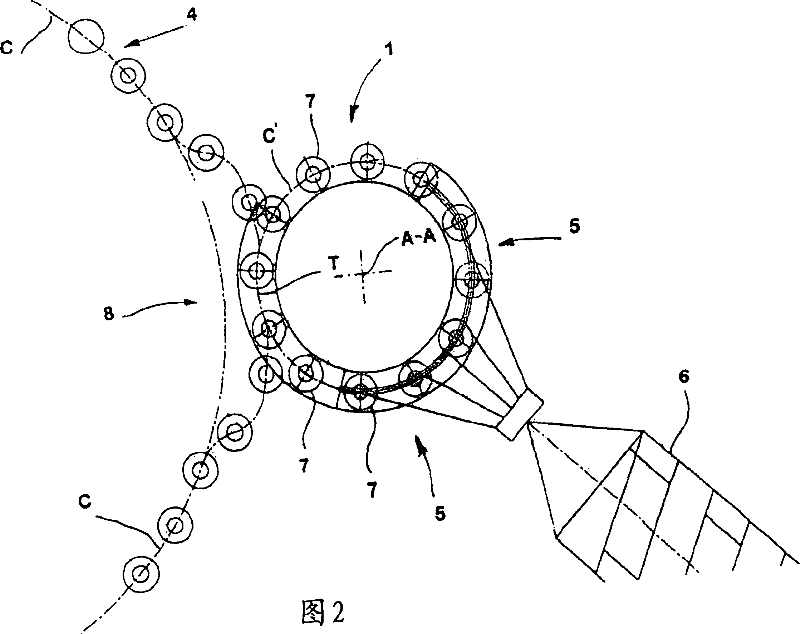

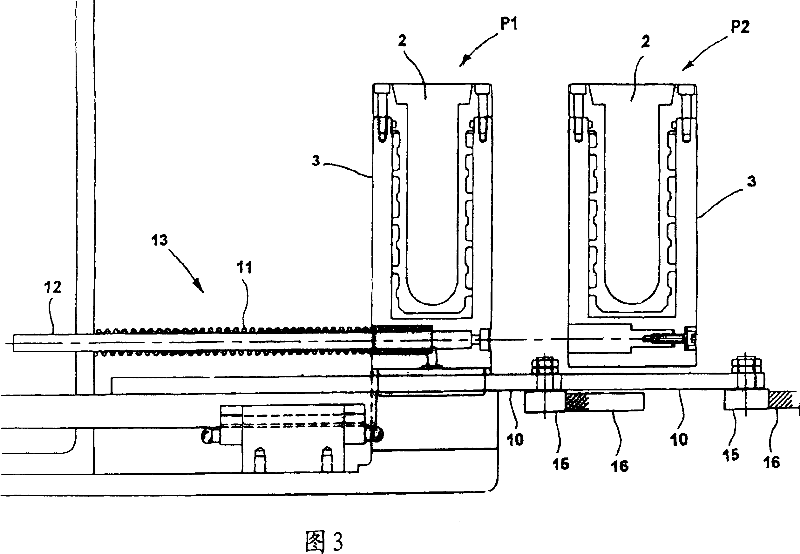

[0031] 1 to 4 schematically show a preferred example of a plant for the production of molded plastic objects using the compression molding method of the present invention, said plant comprising a filling station 1 , a compression station 4 . The filling station 1 is able to pour a predetermined quantity of plastic material to be molded into the mold cavity 2 of the female mold half 3 . The filling equipment of Figures 1 and 2 comprises a rotating carousel (or filling carousel), which rotates in zone 5 around a vertical axis A-A, continuously quantifying the plastic material extruded from mastication screw 6 picked up into variable-volume cavities 7, for example arranged near the outer edge of the filling carousel, and carried to the discharge area 8, where the plastic material is poured into the female half cavity 2 (FIG. 3) of the mold 3, causing them to flow out through an opening (not shown) in each dosing cavity 7. In the example shown, the openings of the different varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com