Device for electronically contacting an electrically conductive part of a high-frequency system

A technology of conductive parts and electrical contact, applied in the direction of two-part connection device, parts of the connection device, contact parts, etc., can solve the problems of corrosion, brass stress corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

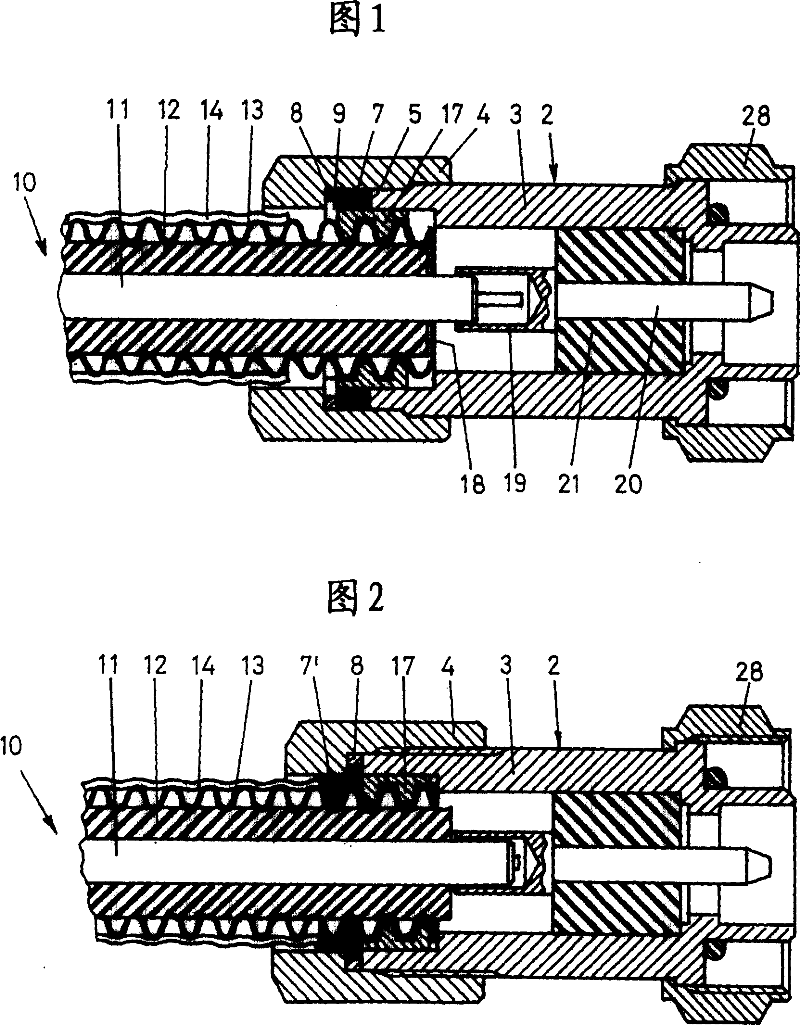

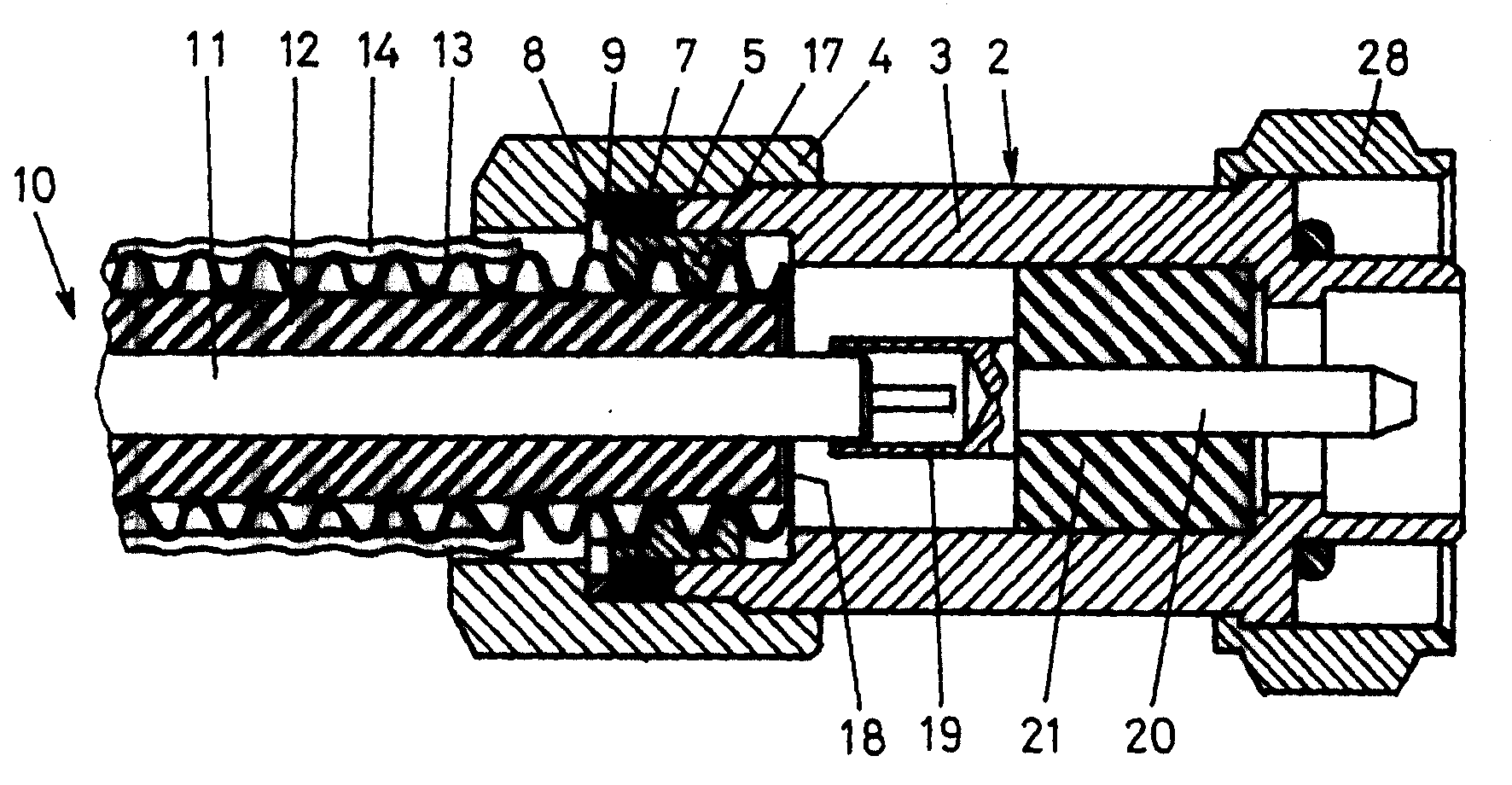

[0009] According to FIGS. 1 and 2 , the high-frequency component is a coaxial plug 2 which has a housing 3 on which a coaxial cable 10 is detachably fastened by means of nuts 4 . The coaxial cable 10 has, in known manner, an inner conductor 11 , an insulator 12 , a corrugated tube sheath 13 as outer conductor, and an outer jacket 14 . The inner conductor 11 is connected via the connecting sleeve 9 to a plug pin 20 which is surrounded by an insulator 21 . The coaxial plug 2 is screwed by a further nut 28 to a plug part (not shown here).

[0010] In FIG. 1 , the nut 4 has not been completely screwed onto the housing 3 . During the further screwing of the nut 4 into the position shown in FIG. 2 , a seal 7 , for example made of synthetic rubber, partially enters an annular space 9 so that a threaded ring screwed onto the bellows sheath 13 17 is isolated and sealed from the outside world. As shown in the figure, the front end of the bellows sheath 13 is deformed during screwing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap