Gas-liquid separator

A technology of gas-liquid separator and separation chamber, which is applied in the field of gas-phase and liquid-phase separators. It can solve the problems of unstable internal swirling airflow, improved separation effect of mixed gas-liquid flow, and large space volume, and achieves a compact structure. , Improve the separation effect and reduce the effect of space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

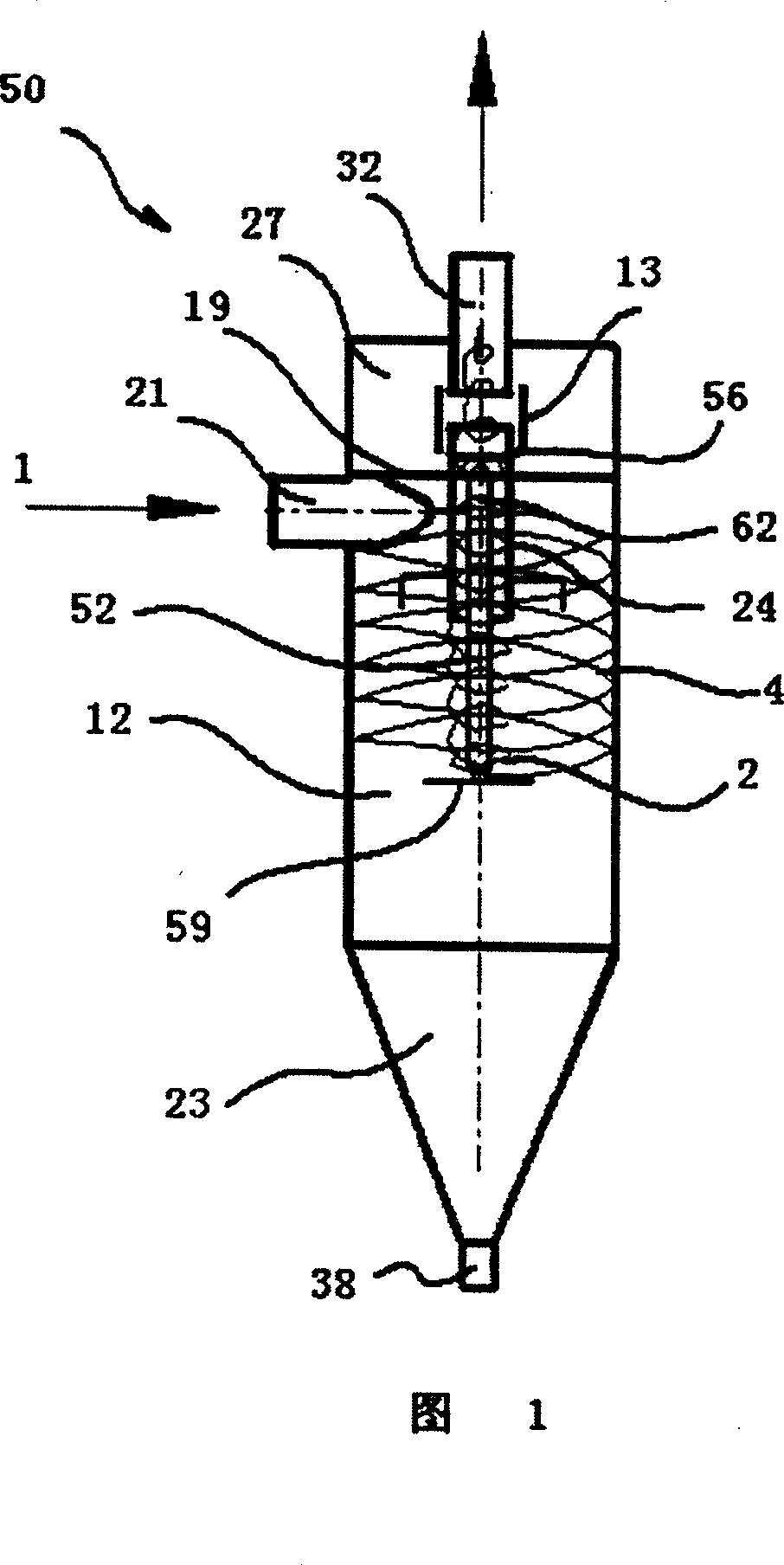

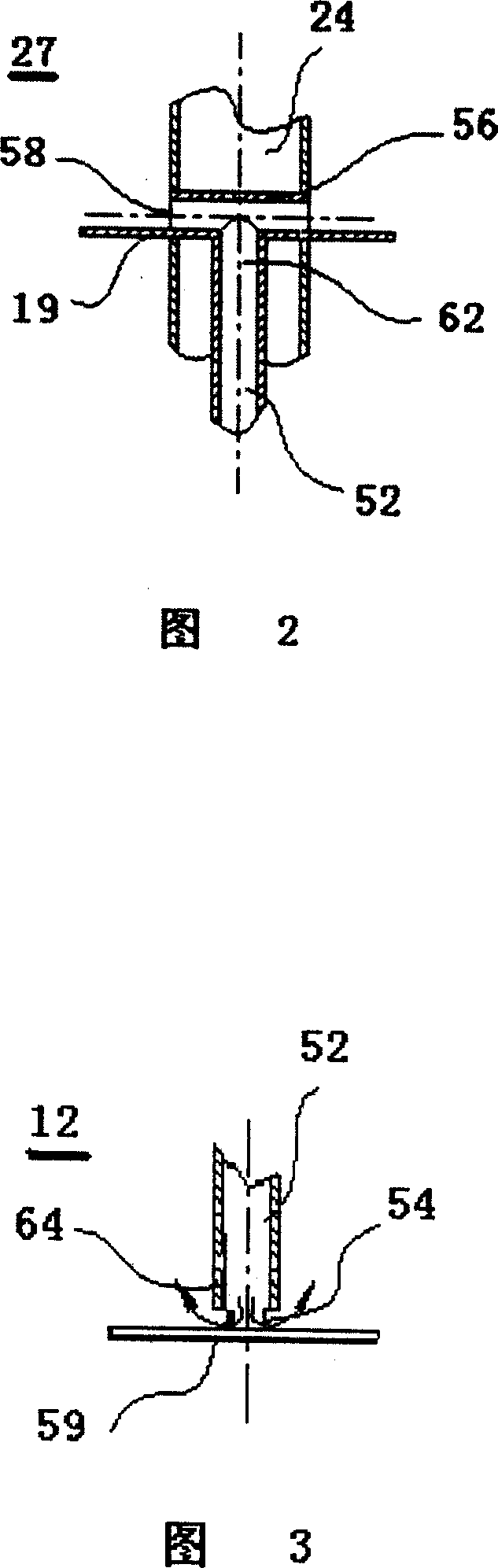

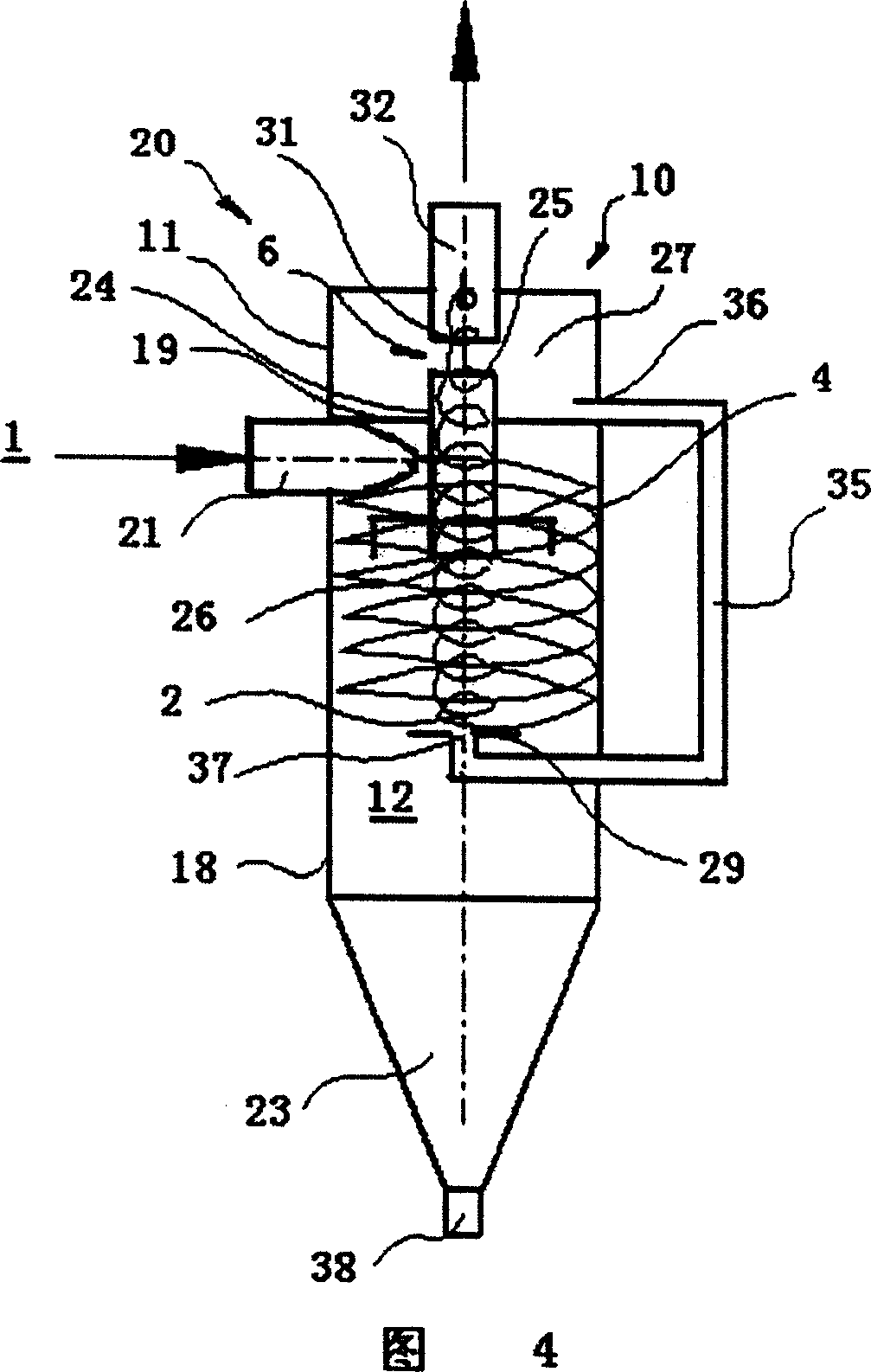

[0015] With reference to accompanying drawing 1, a kind of gas-liquid separator 50 that the present invention provides, it comprises separation chamber 12, is provided with the inlet 21 of mixed gas-liquid flow 1 on separation chamber 12, and one end of separation chamber 12 has separation chamber 27 again, A partition 19 is provided between the separation chamber 12 and the re-separation chamber 27 . The chimneys 24 respectively extend toward both sides of the partition plate 19 . One end 26 of the gas riser 24 is located in the separation chamber 12 , the other end 25 is located in the re-separation chamber 27 and is opposite to the end 31 of the exhaust pipe 32 , and the other end of the separation chamber 12 has a liquid collection chamber 23 . The circulation pipe 52 is located inside the separation chamber 12, and the longitudinal axis of the circulation pipe 52 extends in the same direction as the longitudinal axis of the separation chamber 12. A part of the circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com