Small cross steel tapping control method for continous steel billet neating furnace

A technology of medium-thin slab continuous casting and steel slab heating, which is applied in heat treatment process control, lighting and heating equipment, furnaces, etc. It can solve the problems of not too many steel blocks, product quality fluctuations, and large fluctuations. The effect of accurate value and improved thickness accuracy

Inactive Publication Date: 2008-01-23

ANGANG STEEL CO LTD

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1. The production coordination is not good, and the output is affected. Because one furnace is out of steel and the other is waiting (big cross billet out of steel), the slab leading to another furnace is heated in the furnace for too long, which greatly exceeds the specified in-furnace time, and the temperature of the steel slab at the end of the slab itself does not meet the requirements, resulting in reduced output and increased energy consumption. The number of steel blocks should not be too many, otherwise it will affect the tapping of another furnace

[0004] 2. Unstable billet temperature leads to unstable product temperature. The general rule is that the temperature of the first billet is the lowest, the temperature of the second block increases, and the temperature of the third block is the highest, and then gradually decreases. The impact is that the thickness accuracy of single furnace products is controlled. Unstable and large fluctuations. On the other hand, the temperature of the billets in the two furnaces is inconsistent, which also affects the product precision control, and the product quality fluctuates greatly.

[0005] 3. It is not easy to carry out automatic control production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

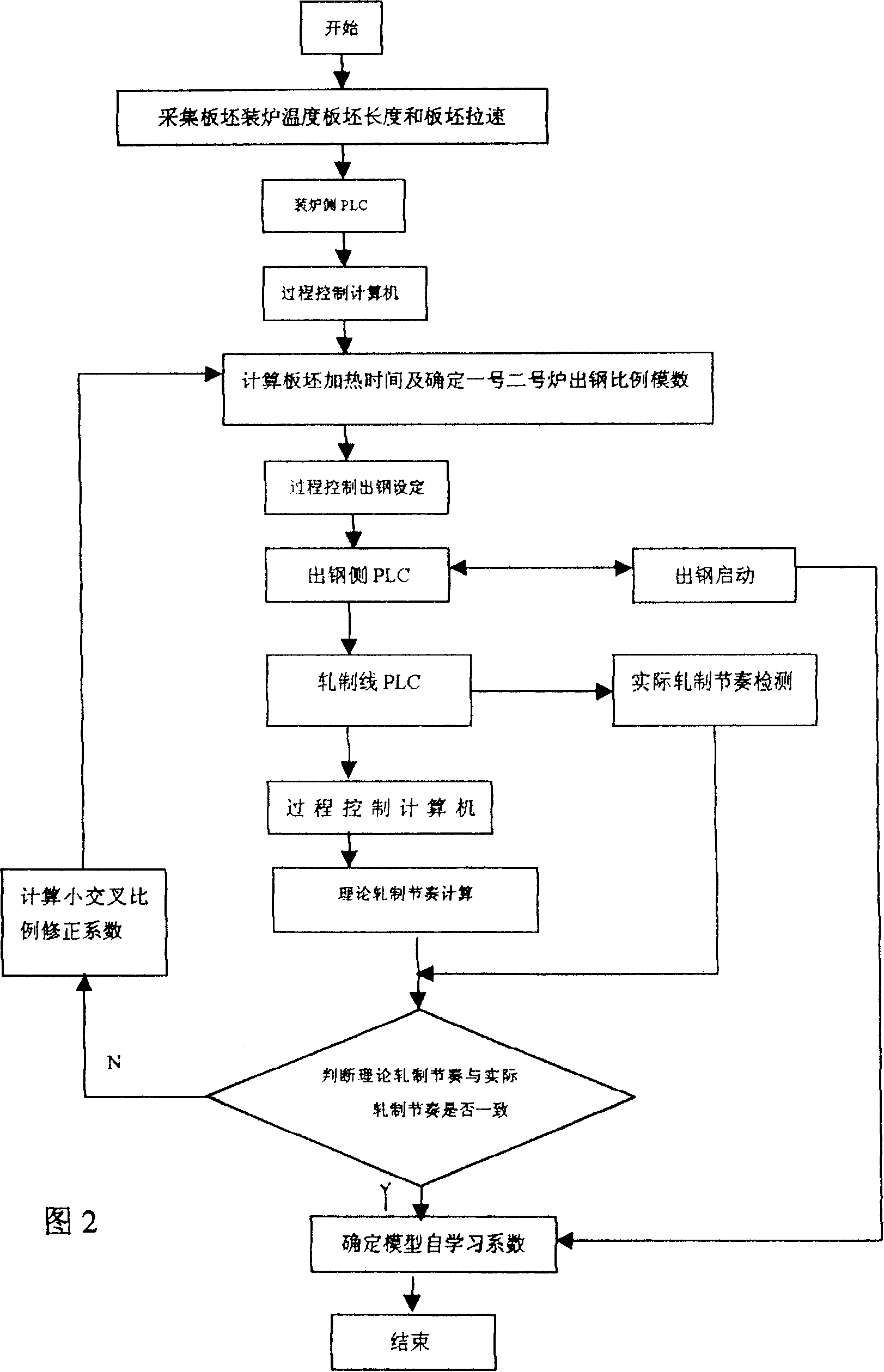

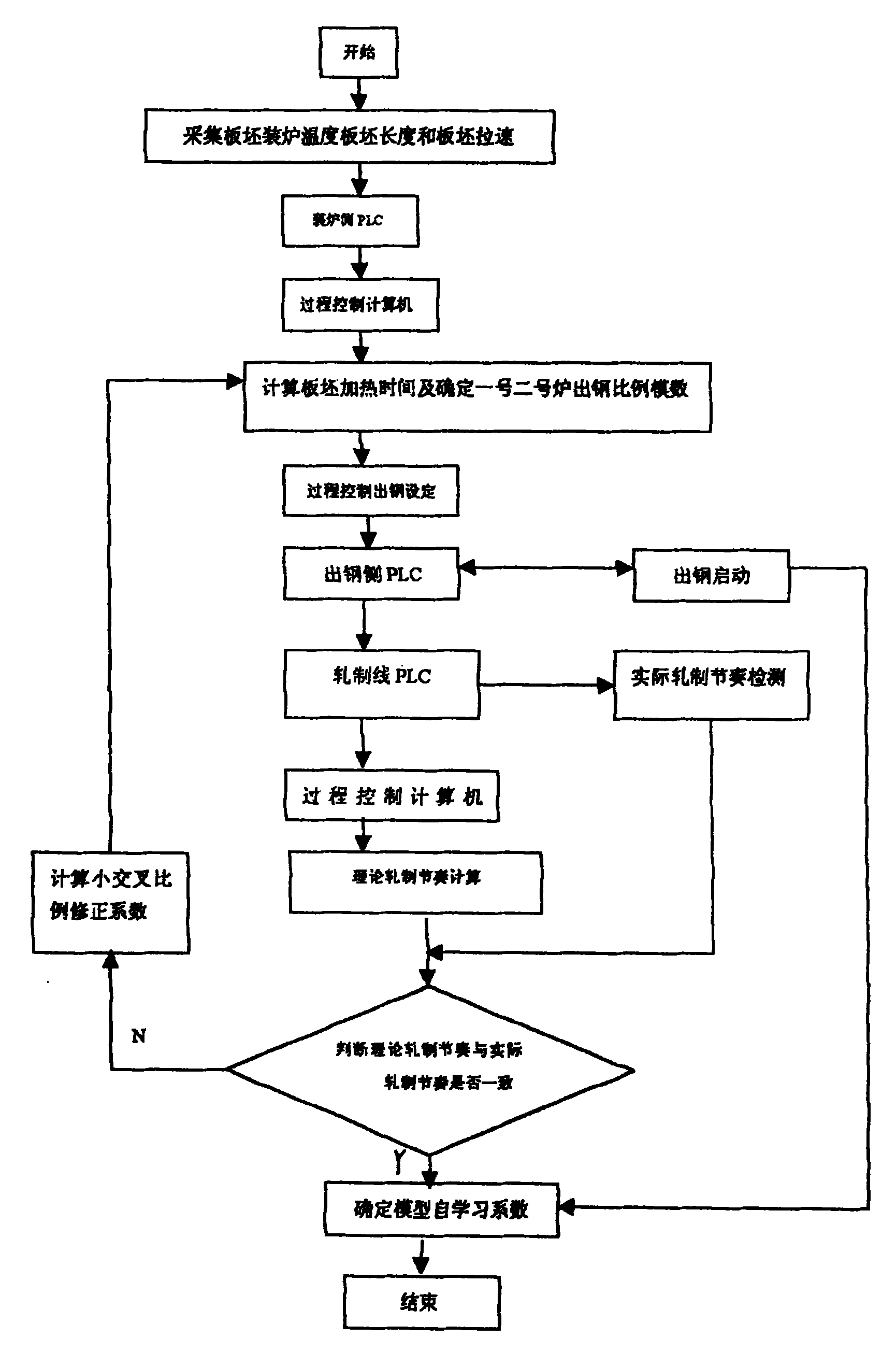

[0032] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

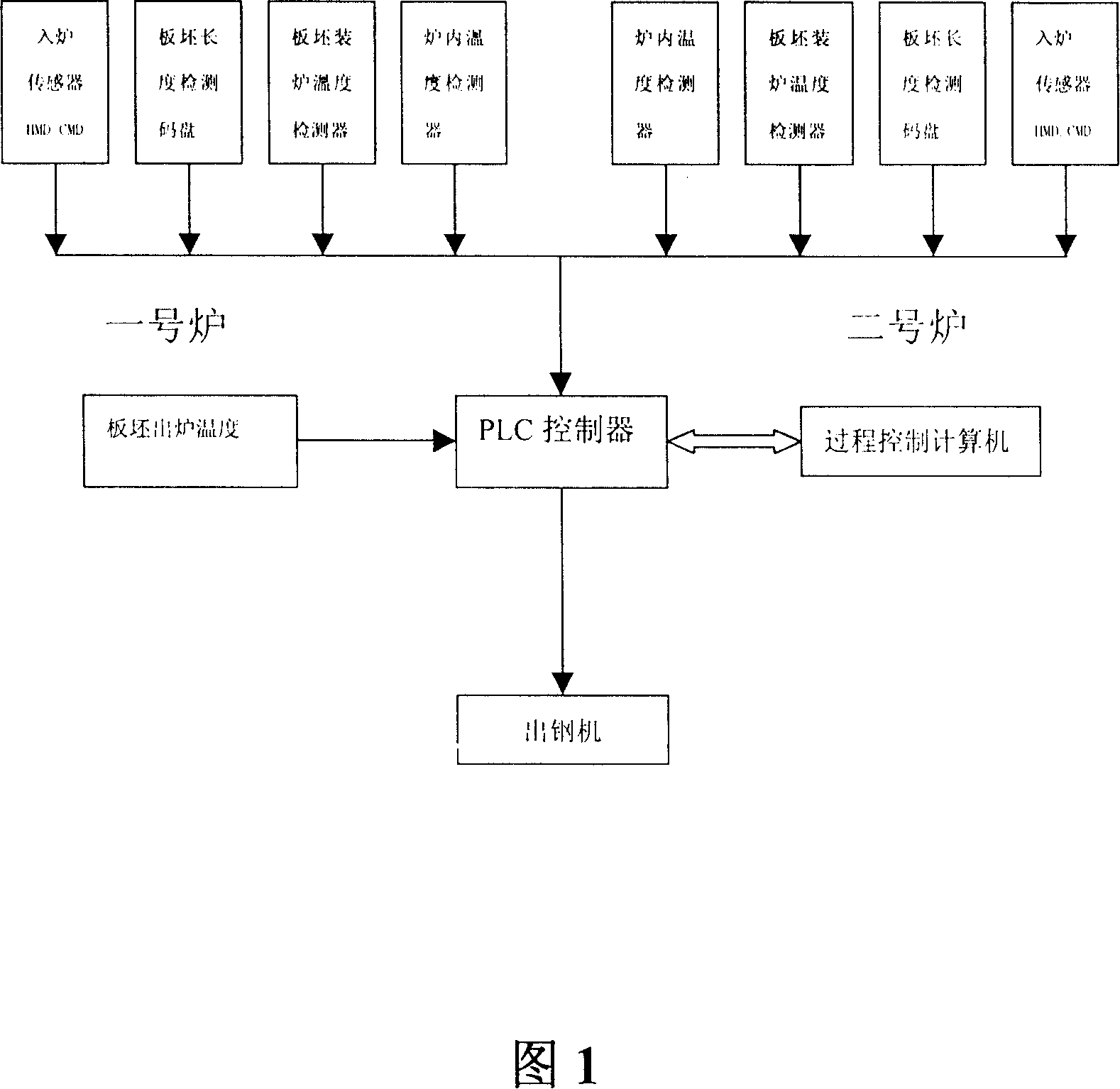

The present invention discloses a small-cross tapping control method of continuous cast billet heating furnace, and is characterized by that at charging side of two heating furnaces a furnace-charging sensor, slab length detection disk and slab furnace-charging temp. detector are mounted, in the interior of the furnace a detector is mounted and at tapping hole a heat metal detector is mounted. The slab length signal, billet furnace-charging temp. signal and slab pulling speed signal are transferred into PLC and process control computer, and the computer can be used for making operation and comparison so as to obtain the optimized tapping modulus of two furnaces and can implement slab small-cross tapping control of two heating furnaces.

Description

technical field [0001] The invention belongs to the production field of hot-rolled plates and strips, and is a tapping control method for automatically controlling the small intersection of double continuous casting billet heating furnaces. Background technique [0002] Currently, two walking heating furnaces are matched with the continuous casting machine. Since the two heating furnaces are generally inconsistent regardless of the furnace charging temperature of the slab, or the finished slab specification and steel type, the two different heating furnaces The following problems will occur when billets of different specifications in the furnace are heated and tapped: [0003] 1. The production coordination is not good, and the output is affected. Because one furnace is out of steel and the other is waiting (big cross billet out of steel), the slab leading to the other furnace is heated in the furnace for too long, which greatly exceeds the specified in-furnace time, and th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D11/00F27B14/20

Inventor 黄浩东曲成惠沙孝春史乃安杨旭赵林邹波付国利吴胜田

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com