Multi sound-proof layer floor

A sound insulation layer and floor technology, applied in the direction of insulation layer, layered products, floors, etc., can solve the problems of stiff walking effect, affect the use effect, poor use effect, etc., and achieve convenient installation, placement and repeated use, Good use effect and wood saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific implementation plan

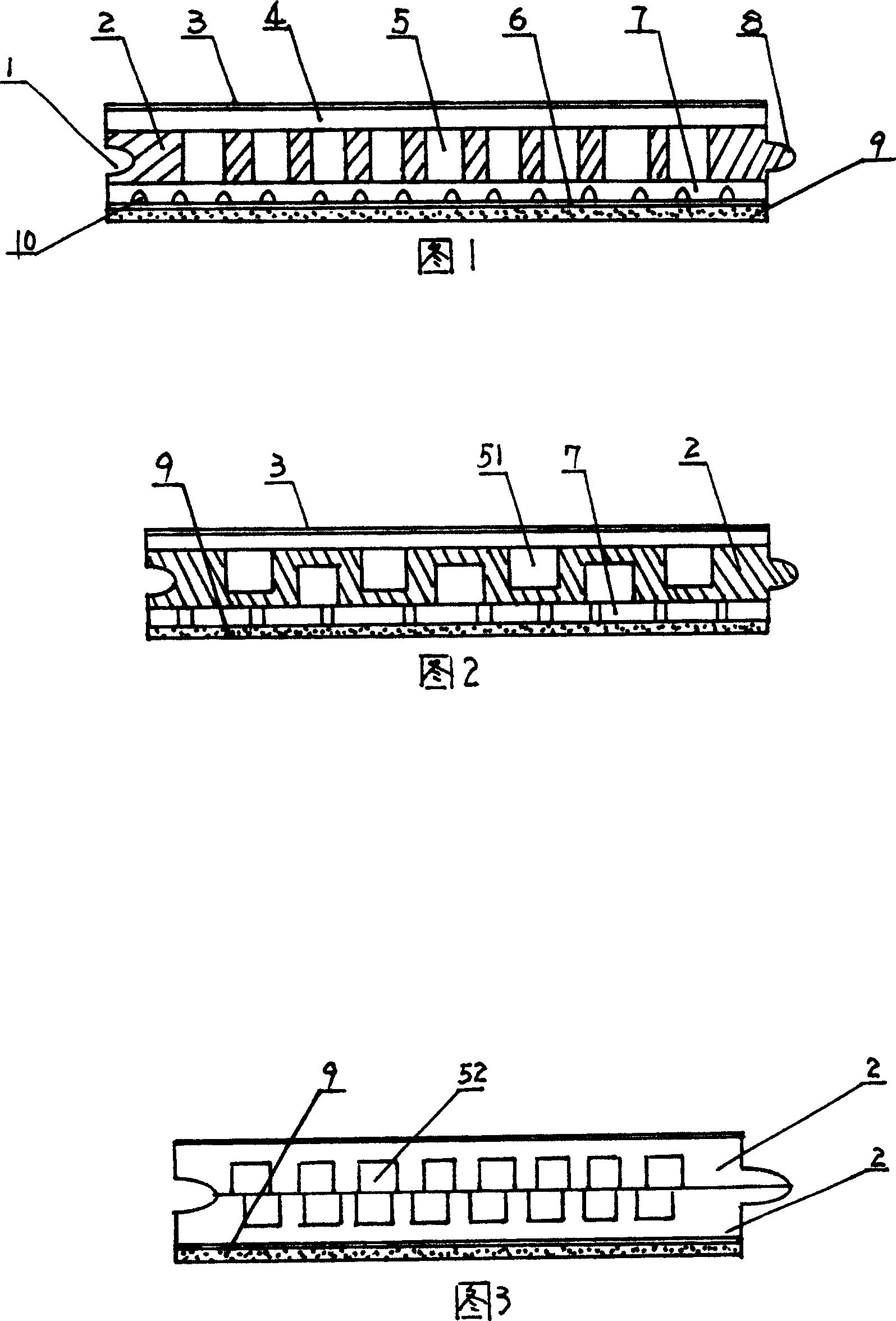

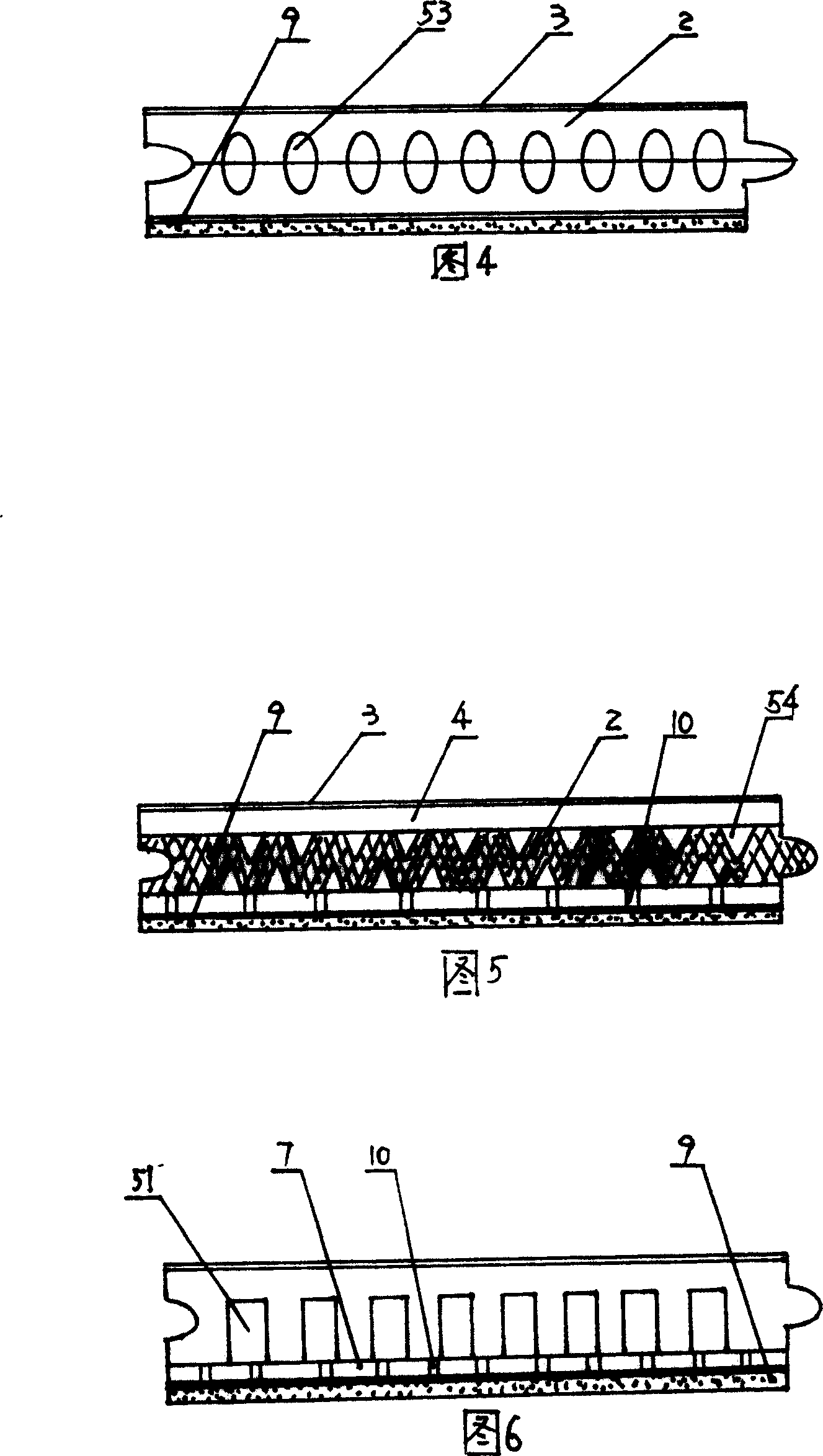

[0015] As shown in Figs. 1 to 6, a multi-layer sound insulation floor is composed of a surface layer 3 and an upper layer material 4.

[0016] The multi-layer sound insulation floor includes at least two sound insulation layers. The first sound insulation layer 2 is located between the surface layer and the bottom layer 6, or between the surface layer and the lower layer material 7, and the first sound insulation layer is composed of materials distributed on this layer. Sound insulation hole grooves 5 are formed. The second sound insulation layer is located on the lower end surface of the bottom layer or the lower end surface of the lower layer material, the second sound insulation layer 9 is composed of a material with sound absorption function, and a lower layer material is arranged between the bottom layer and the first sound insulation layer;

[0017] Or multi-layer sound insulation floors include at least two sound insulation layers, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap