Die cushion drive system

A buffer mechanism and drive device technology, applied in the direction of output power conversion devices, presses, manufacturing tools, etc., can solve problems such as energy consumption, and achieve the effect of miniaturization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

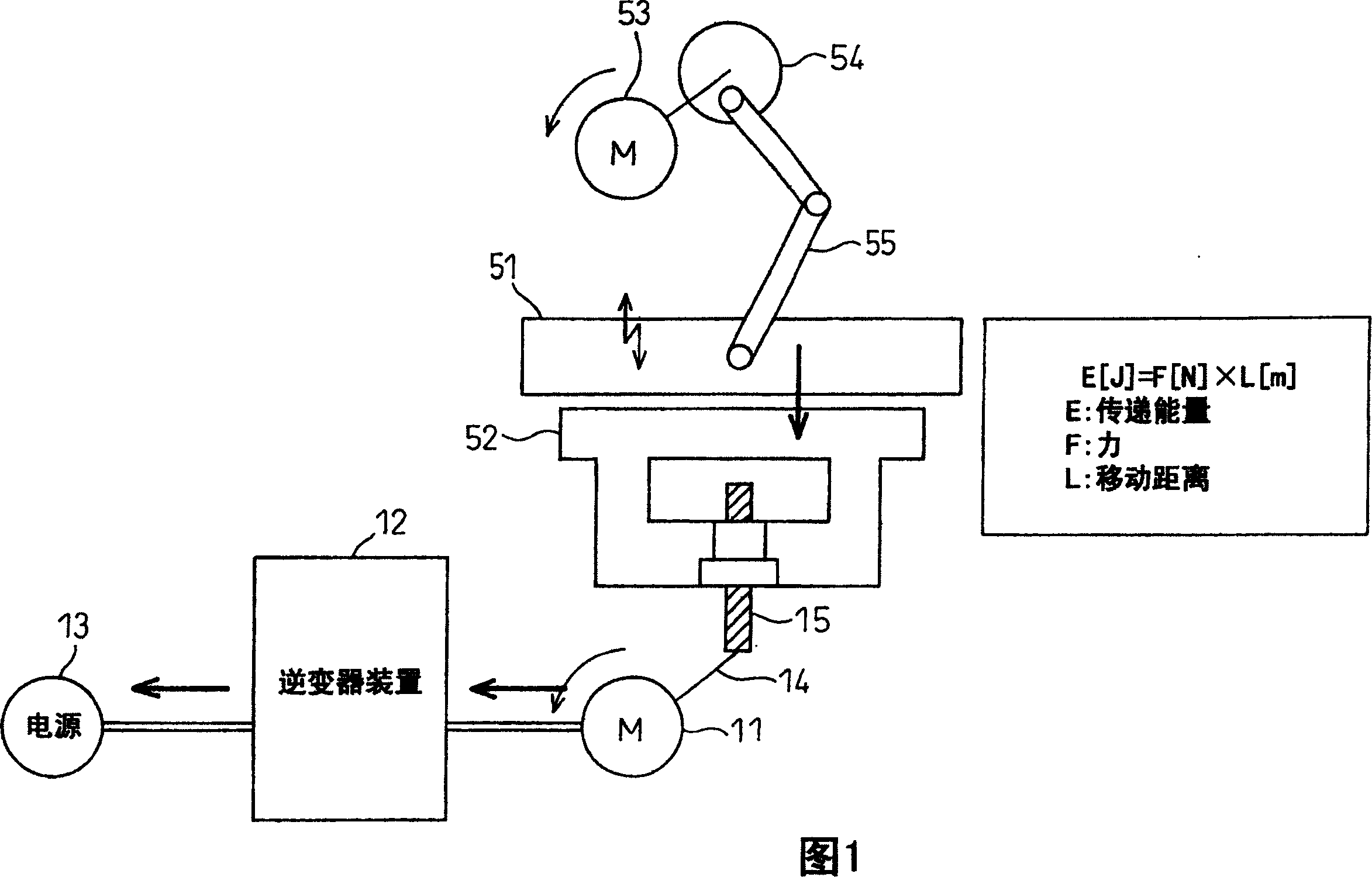

[0023] FIG. 1 is a side view showing the configuration of a die cushion mechanism driving device of a press machine according to an embodiment of the present invention. In this figure, the same reference numerals are assigned to the same parts as the conventional configuration shown in FIG. 5 , and description thereof will be omitted here. In this embodiment, there are provided: a servo motor 11 for driving the mold buffer mechanism 52; an inverter device 12 for supplying AC power to the servo motor 11; phase AC power supply 13 . The rotational energy of the servo motor 11 is given to the shaft 15 of the die cushion mechanism 52 as vertical motion energy through the ball screw 14 .

[0024] During power running, the slider 51 moves downward by the energy from the motor 53, and the inverter device 12 converts the AC power from the three-phase AC power supply 13 into AC power with the frequency and amplitude most suitable for driving the servo motor 11. By driving the servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com