Inverter device for driving electric motor

A technology for inverters and motors, which is applied to electrical devices, AC motor control, electric vehicles, etc. It can solve problems such as inability to switch, poor operation, and changes in the operation status of electric fans and pumps, so as to achieve maintenance and improve operation reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described with reference to illustrated examples.

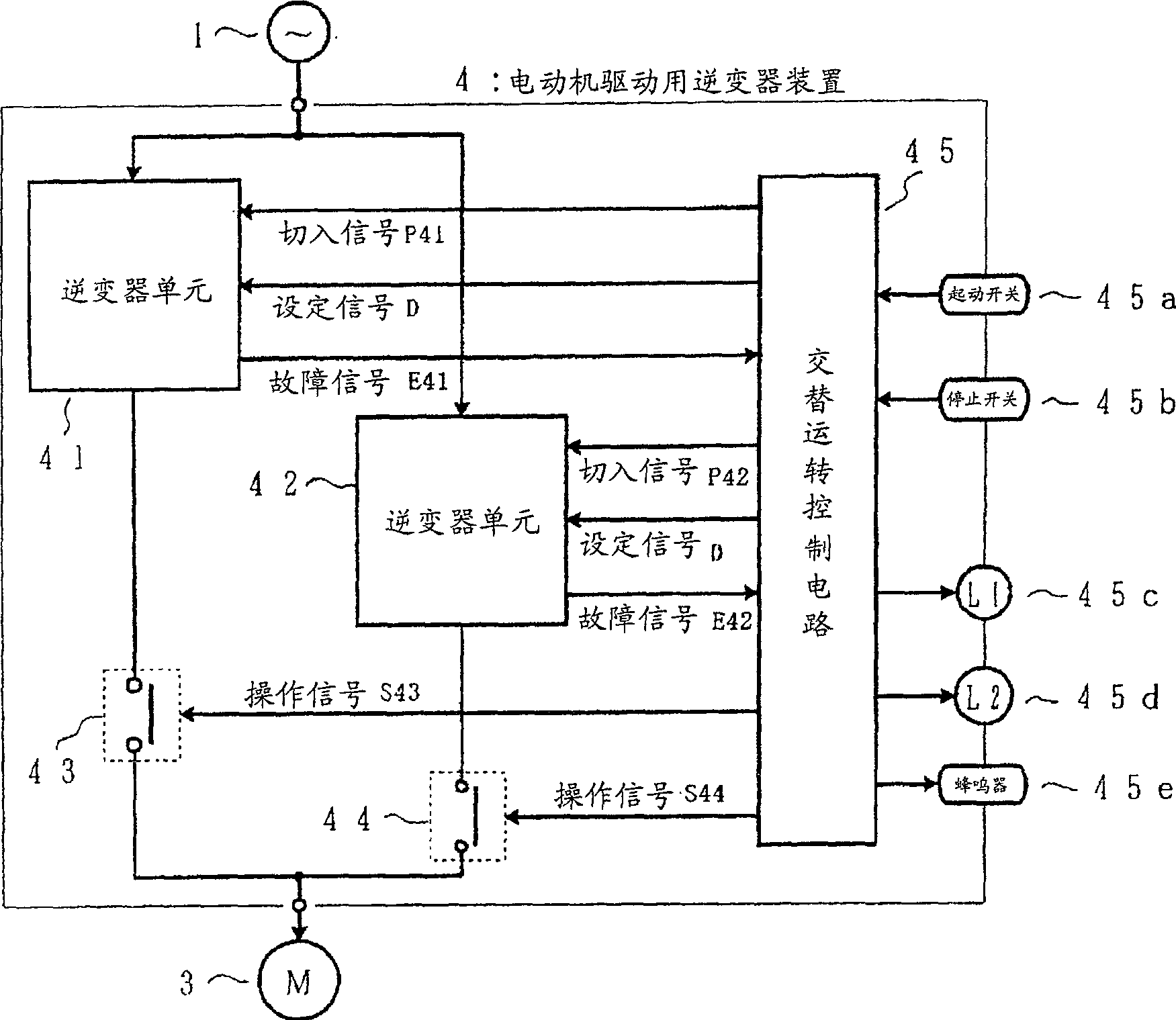

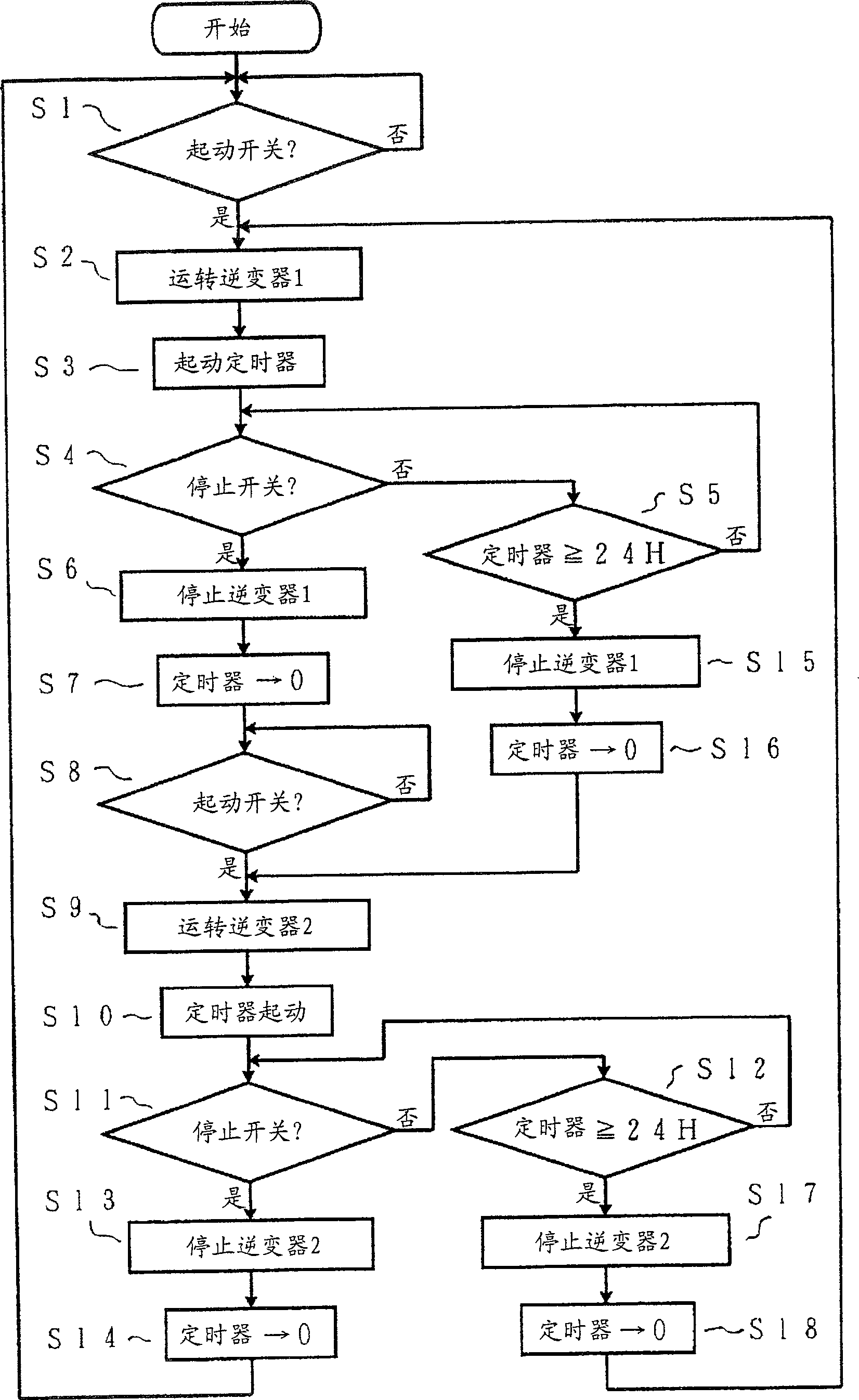

[0025] figure 1 It is a circuit configuration diagram showing a first embodiment of the inverter device for driving a motor according to the present invention. pair with Figure 6 The same functional elements as the structural elements of the shown conventional example are given the same reference numerals.

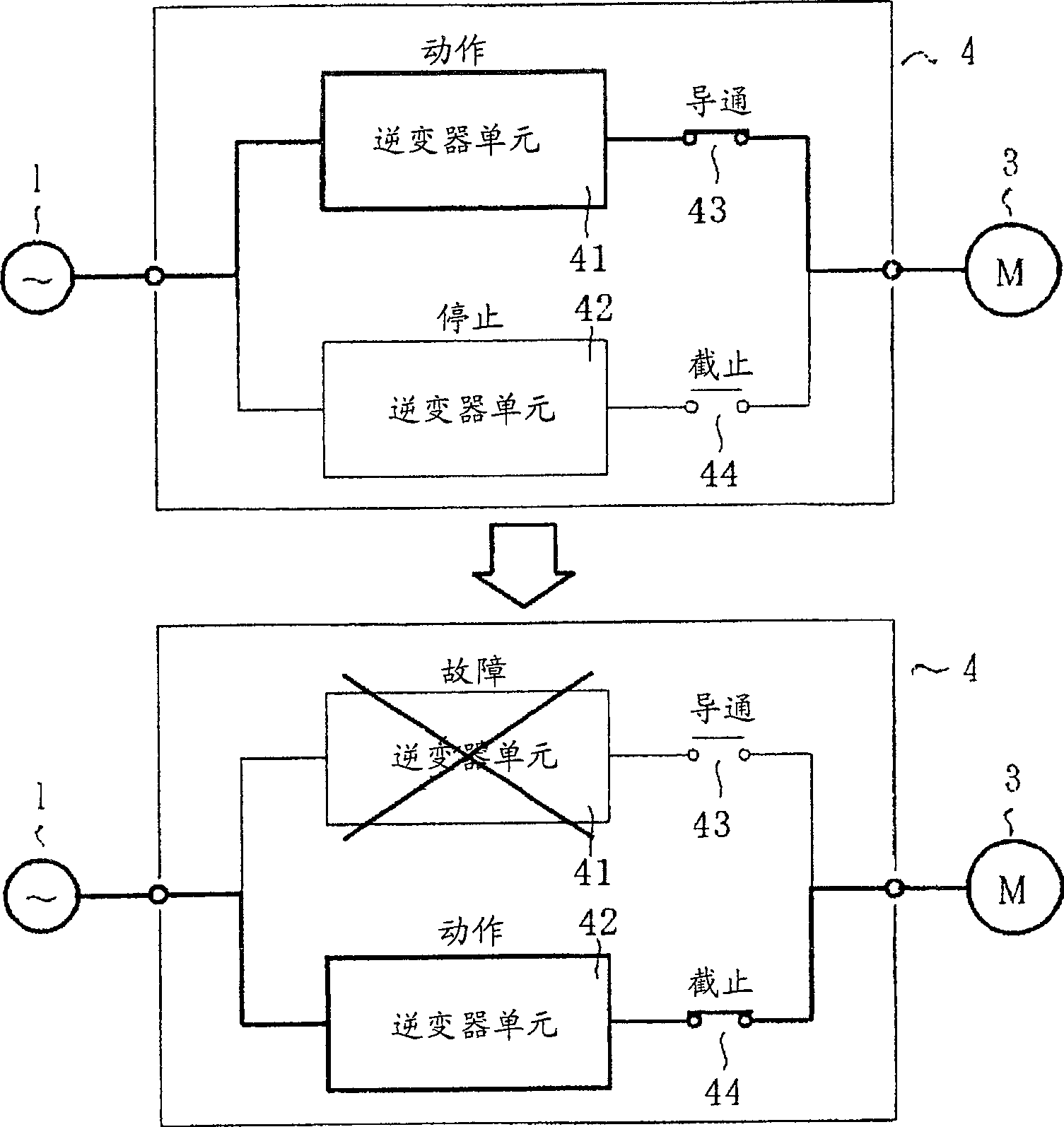

[0026] which is, figure 1 The shown inverter device 4 for driving a motor has two sets of inverter units 41 and 42 that are completely unitized like a general-purpose inverter and can independently generate AC power of variable voltage and variable frequency. A set of electromagnetic contactors 43, 44, and a set of alternate operation control circuits 45. The purpose of providing the electromagnetic contactors 43 and 44 is to switch between the motor 3 and the inverter by turning on the side connected to the operating inverter unit and turning off the side connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com