Intelligent lock with straight handle

A technology of smart lock and straight handle, applied in the field of locks, can solve the problems of not being compact and neat, and the area of the lock body being large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

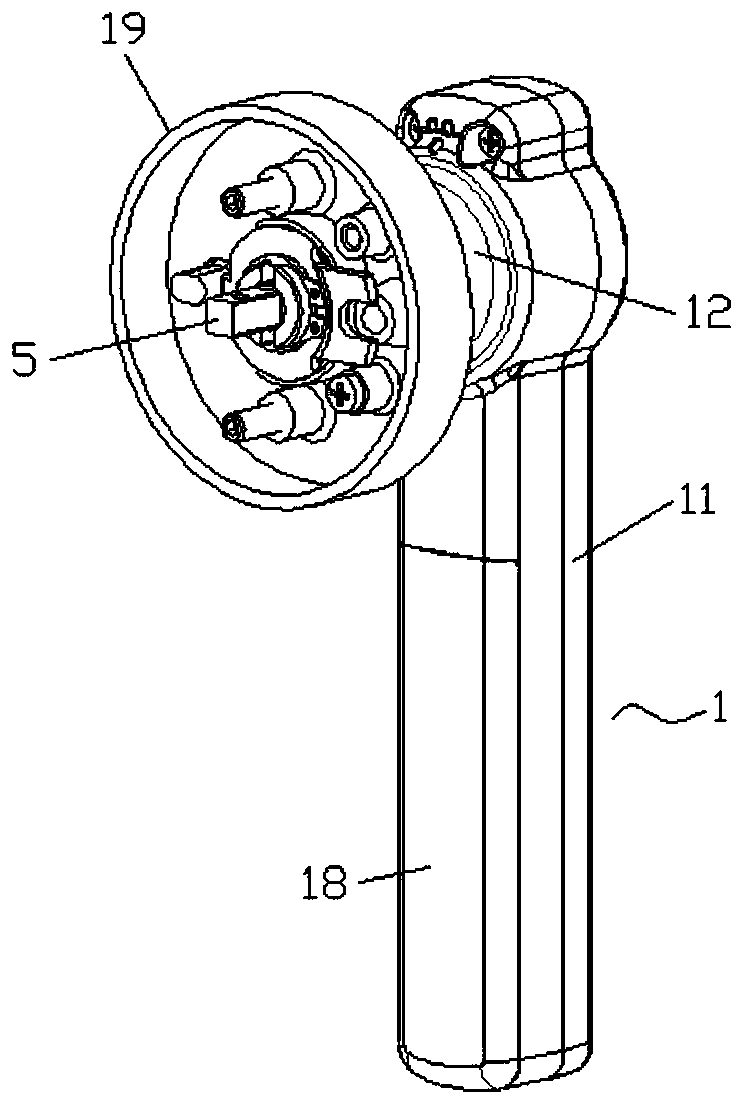

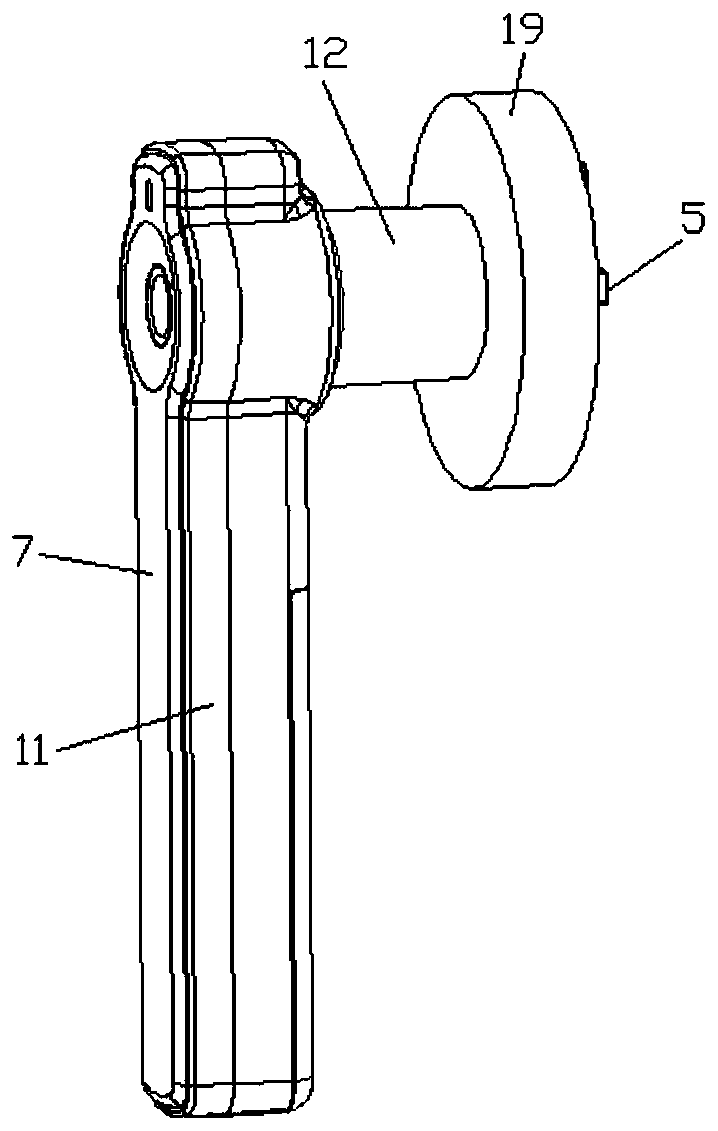

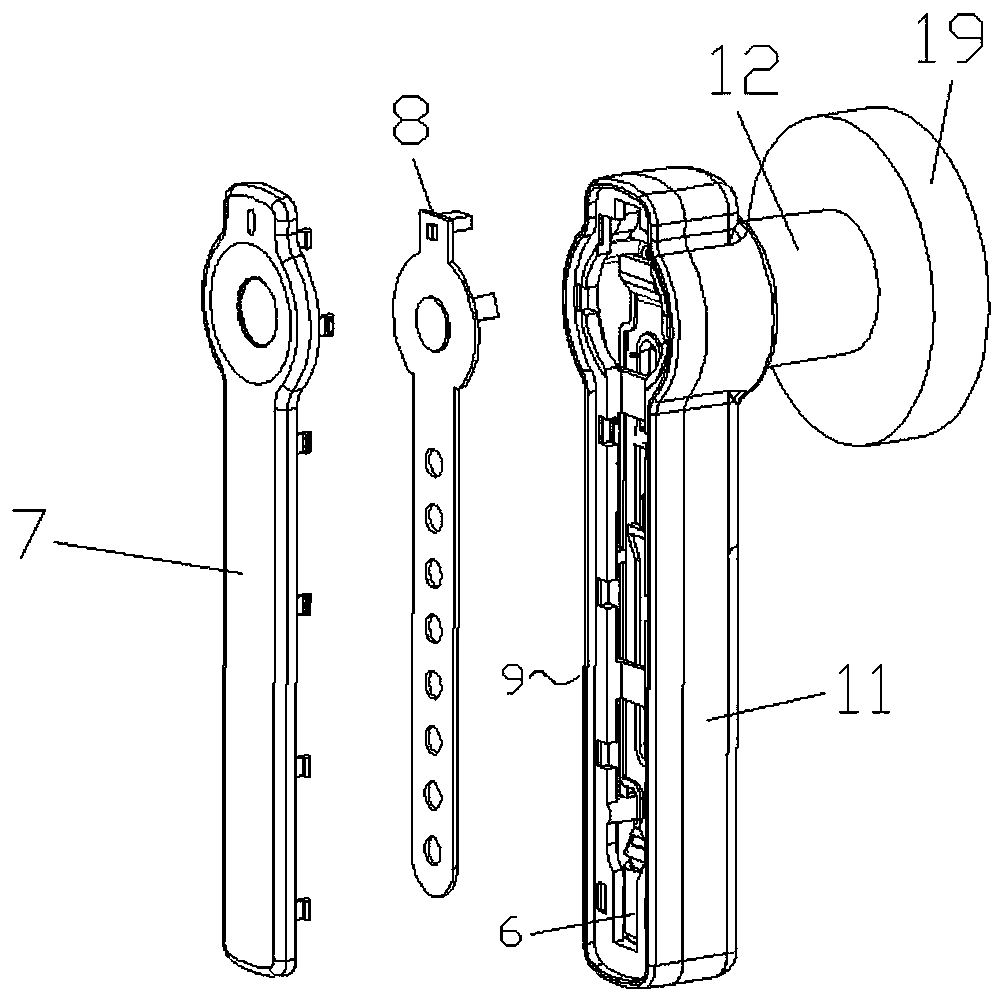

[0030] Such as Figure 1-Figure 7 As shown, the straight-handle smart lock of the present application includes a handle 1, a motor reset mechanism 2, a connecting shaft 3, a fixing seat 4, a handle 5, a lock 6, a touch panel 7 and a circuit board 8; the grip of the handle 1 The holding portion 11 and the bending portion 12 are provided with a communicating cavity, the motor implementing reset mechanism 2 is installed in the cavity of the bending portion 12, the connecting shaft 3 is slidingly mounted on the motor implementing reset mechanism 2, and the connecting shaft 3 The sliding direction is consistent with the axial direction of the connecting shaft 3. The fixed seat 4 is installed on the motor reset mechanism 2, the handle 5 is rotated and installed on the fixed seat 4, the handle 5 passes through the bending part 12, and the fixed seat 4 is provided with In the through hole 41 through which the connecting shaft 3 passes, a connecting groove 51 is provided on the handle 5...

Embodiment 2

[0037] The straight handle smart lock provided in the second embodiment is a further improvement of the straight handle smart lock provided in the first embodiment. Figure 1-Figure 7 On the basis of the second embodiment, the straight handle smart lock provided in the second embodiment further includes a connecting shaft guide plate 16, which is installed in the cavity of the holding portion 11, and the connecting shaft 3 passes through the connecting shaft guide plate 16 and the pressing plate 9 Abutment connection.

[0038] The connecting shaft guide plate 16 guides the movement direction of the connecting shaft 3 to prevent the movement of the connecting shaft 3 from shifting.

[0039] Specifically, the handle 5 includes a handle cover 52 and a handle body 53. The handle body 53 is elongated. One end of the handle body 53 is connected to the handle cover 52. The handle cover 52 is provided with a connecting groove 51 for fixing The seat 4 is provided with a connecting hole 42,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com