Dual-sealing butterfly valve with overhaul sealing ring driven by servo motor

A technology for checking and repairing sealing and servo motors. It is applied in the direction of lifting valves, valve details, and valve devices. It can solve problems such as troublesome maintenance, high cost, and uneven oil pressure output force, and achieve the effect of simple structure, low cost, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

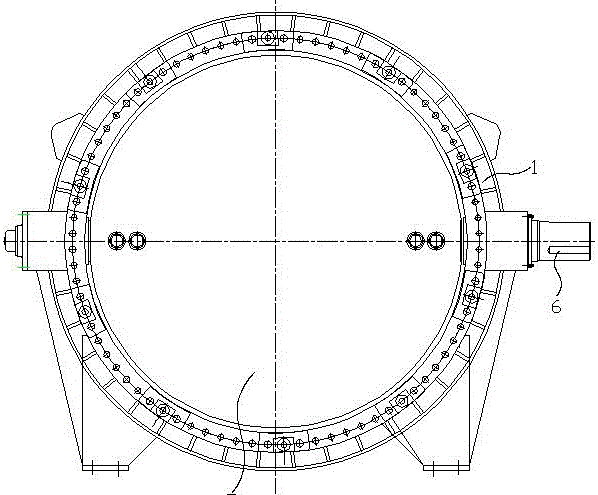

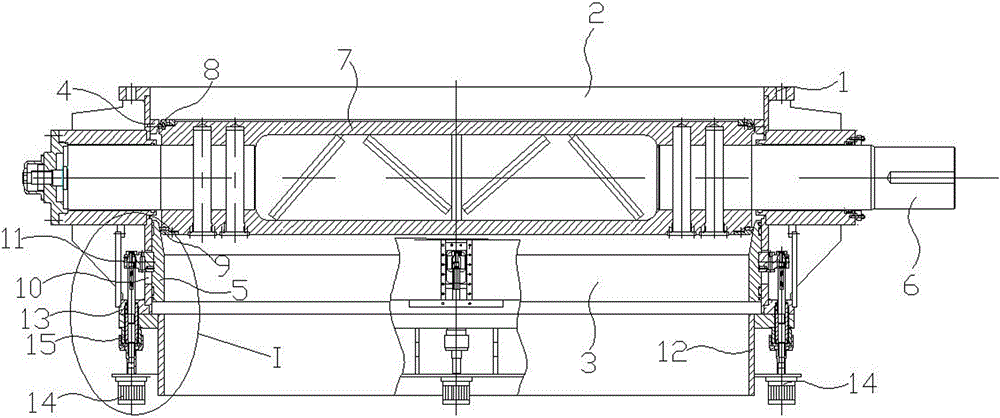

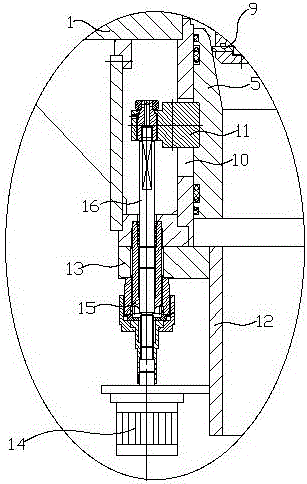

[0020] Figure 1~Figure 4 Among them, the double-channel sealed butterfly valve that uses a servo motor to drive and repair the sealing ring has a cylindrical valve body 1, the front of the valve body is the water outlet 2, the rear of the valve body is the water inlet 3, and the water outlet in the valve body is operated by the valve body. Sealing ring 4, there is a valve body inspection sealing ring 5 that can slide forward and backward on the cylindrical valve body at the water inlet in the valve body, a valve shaft 6 is arranged on the valve body, and a butterfly plate 7 is connected on the valve shaft in the valve body , there are butterfly plate rubber sealing rings 8 matched with valve body working sealing rings and butterfly plate maintenance sealing rings 9 matched with valve body maintenance sealing rings respectively on the butterfly plate. Ten long holes 10 along the axial direction of the valve body are evenly distributed, and the outer circumference of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com