Control equipment of brushless motor and washing machine with the same equipment

A motor control and motor technology, which is applied to the control device of the washing machine, the stop device, and other washing machines, etc., can solve the problems of high cost of the motor control device, consumption of regenerative power, large-scale motor control device, etc., and achieve miniaturization and The effect of lowering the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

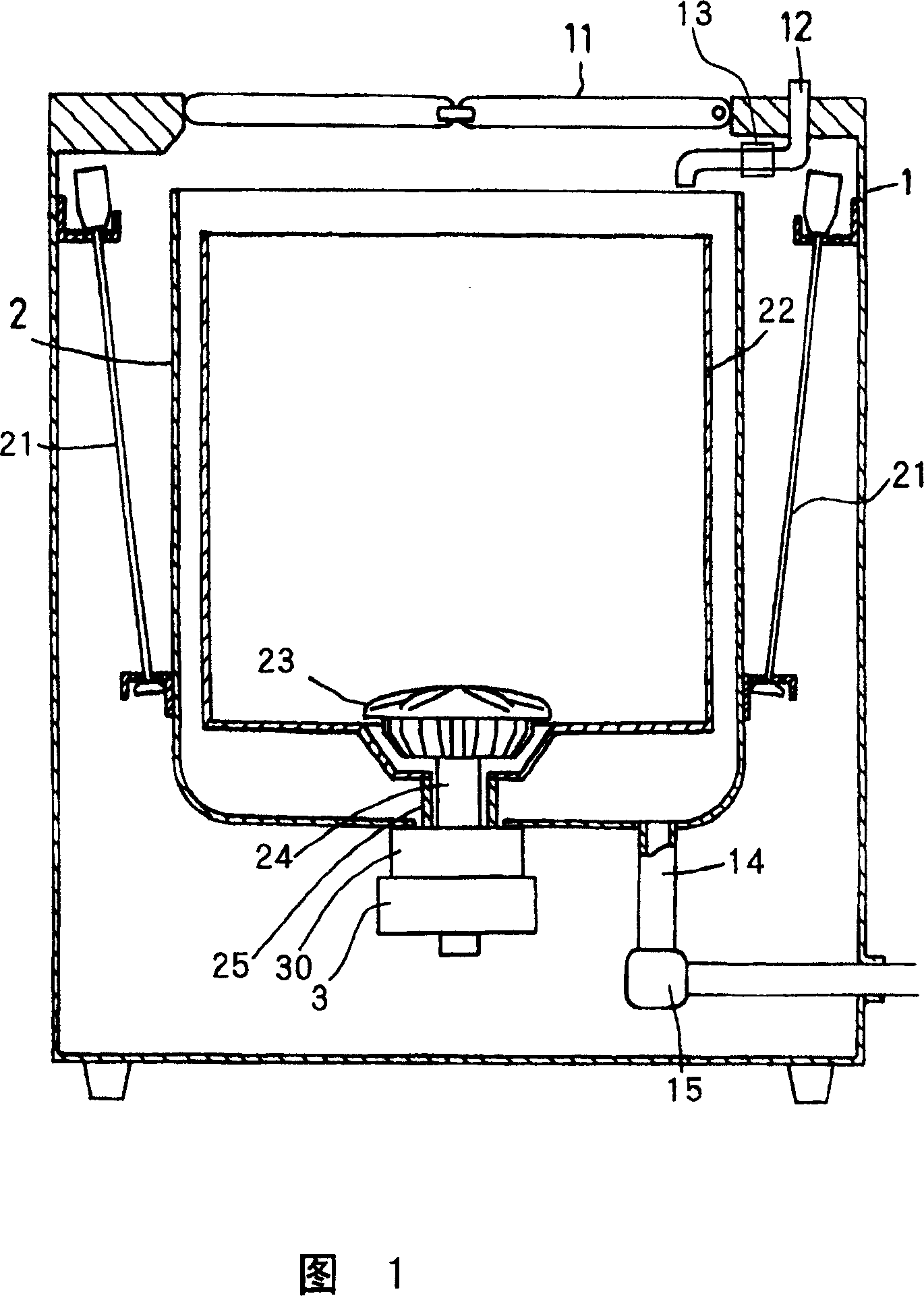

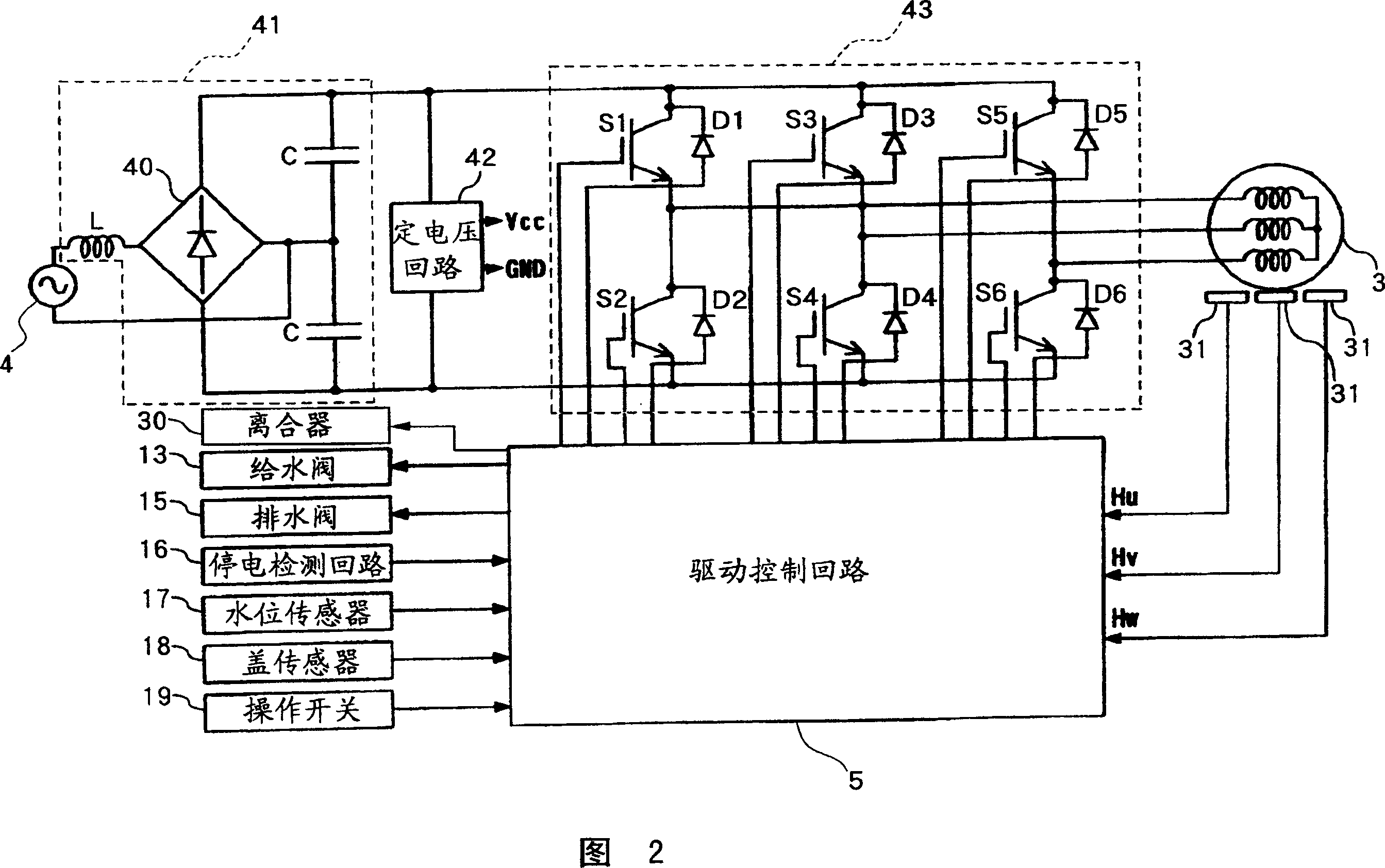

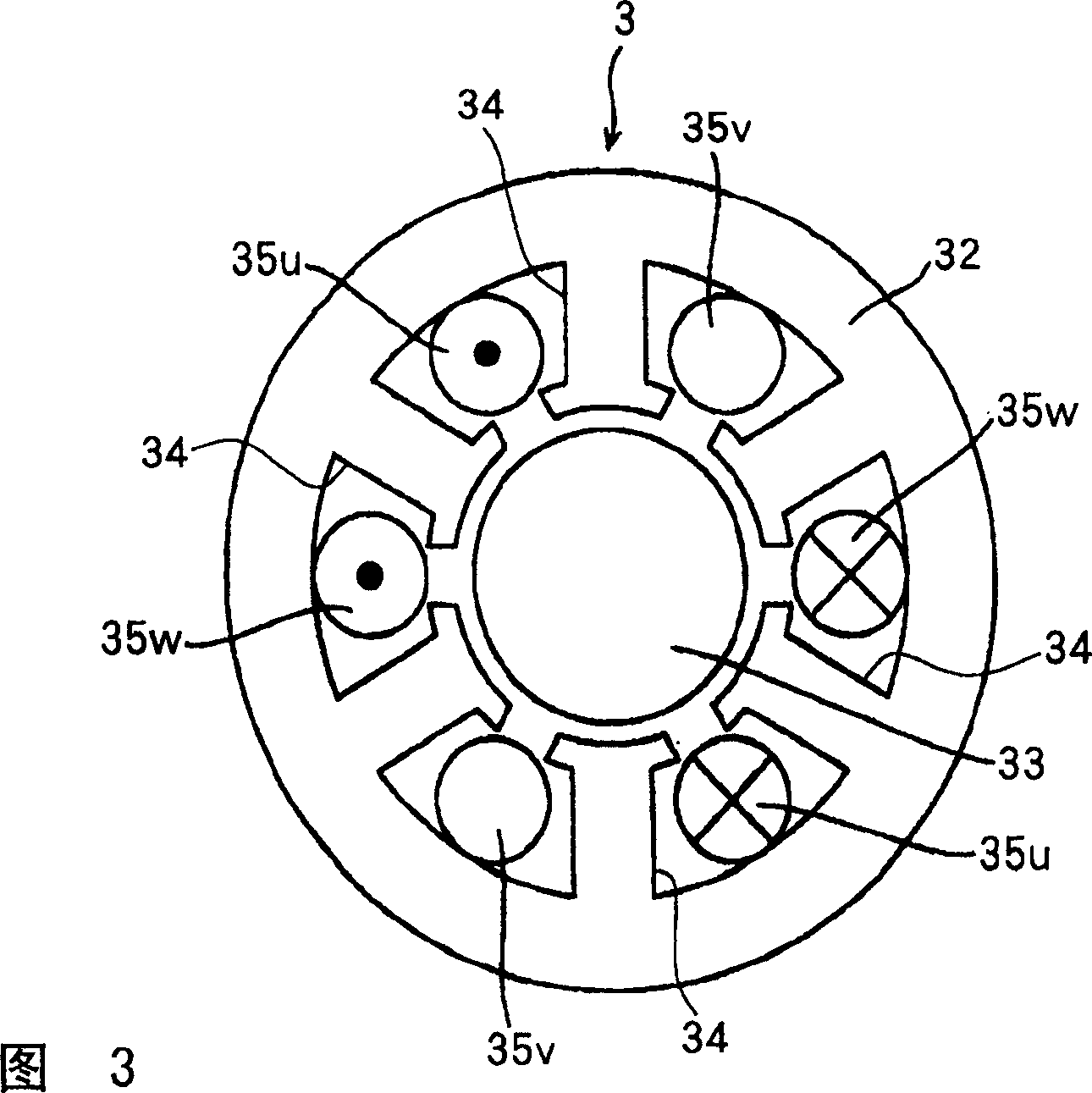

[0067] The vortex type washing machine of the present embodiment is shown in Figure 1, in the inside of frame 1, through 4 suspension rods 21,21,21,21, hang down outer tube 2, in the inside of outer tube 2, can surround A washing tub 22 is accommodated rotatably on a vertical axis. A lid 11 that opens and closes when laundry is thrown into the washing tub 22 is attached to the upper portion of the rack 1 . In addition, a pulse generator 23 is rotatably provided at the bottom of the washing tub 22 to generate a swirling flow of washing water, and a plurality of mountain-shaped blades extending radially protrude from the surface of the pulse generator 23 . In addition, a plurality of through holes (not shown) are opened in the wall surface of the washing tub 22, so that water can be drained during the spin-drying operation.

[0068] Water supply nozzle 12 is installed on frame 1, and water supply valve 13 is housed in the way of water supply nozzle 12. By opening the water sup...

no. 2 example

[0096] In the drum type washing machine of this embodiment, as shown in FIG. 15 , an outer cylinder 60 supported by a vibration suppression mechanism composed of suspension springs 61 , 61 and buffers 62 , 62 is provided inside the frame 6 . Inside the outer tub 60 , a drum 63 for storing laundry is rotatably housed around a horizontal axis, and a cover 64 for putting laundry into the drum 63 is attached to the front of the outer tub 60 . A brushless motor 7 is installed below the urceolus 60 , and the output shaft of the brushless motor 7 is connected to the drive shaft 73 of the drum 63 through a power transmission mechanism composed of a driving pulley 71 , a belt 72 and a driven pulley 73 . Thereby, the drum 63 is rotationally driven. Furthermore, at the end of the drive shaft 74, an acceleration sensor 66 for detecting the acceleration of the drum 63 is mounted.

[0097] On the back surface of the drum 63 , a balance container 65 composed of an annular hollow body is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com