Full automatic sprayer

A sprayer, fully automatic technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of cumbersome operation and high labor intensity, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

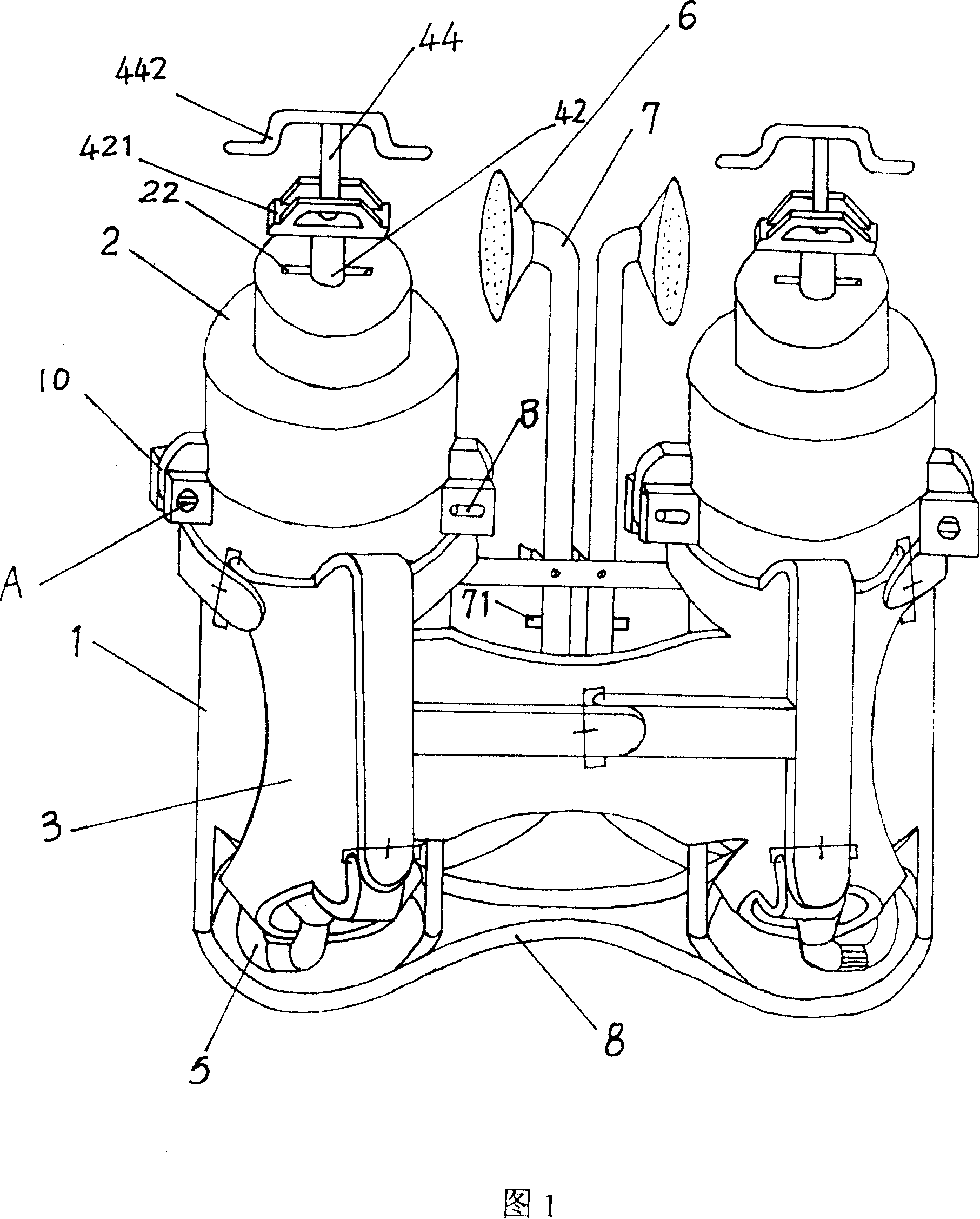

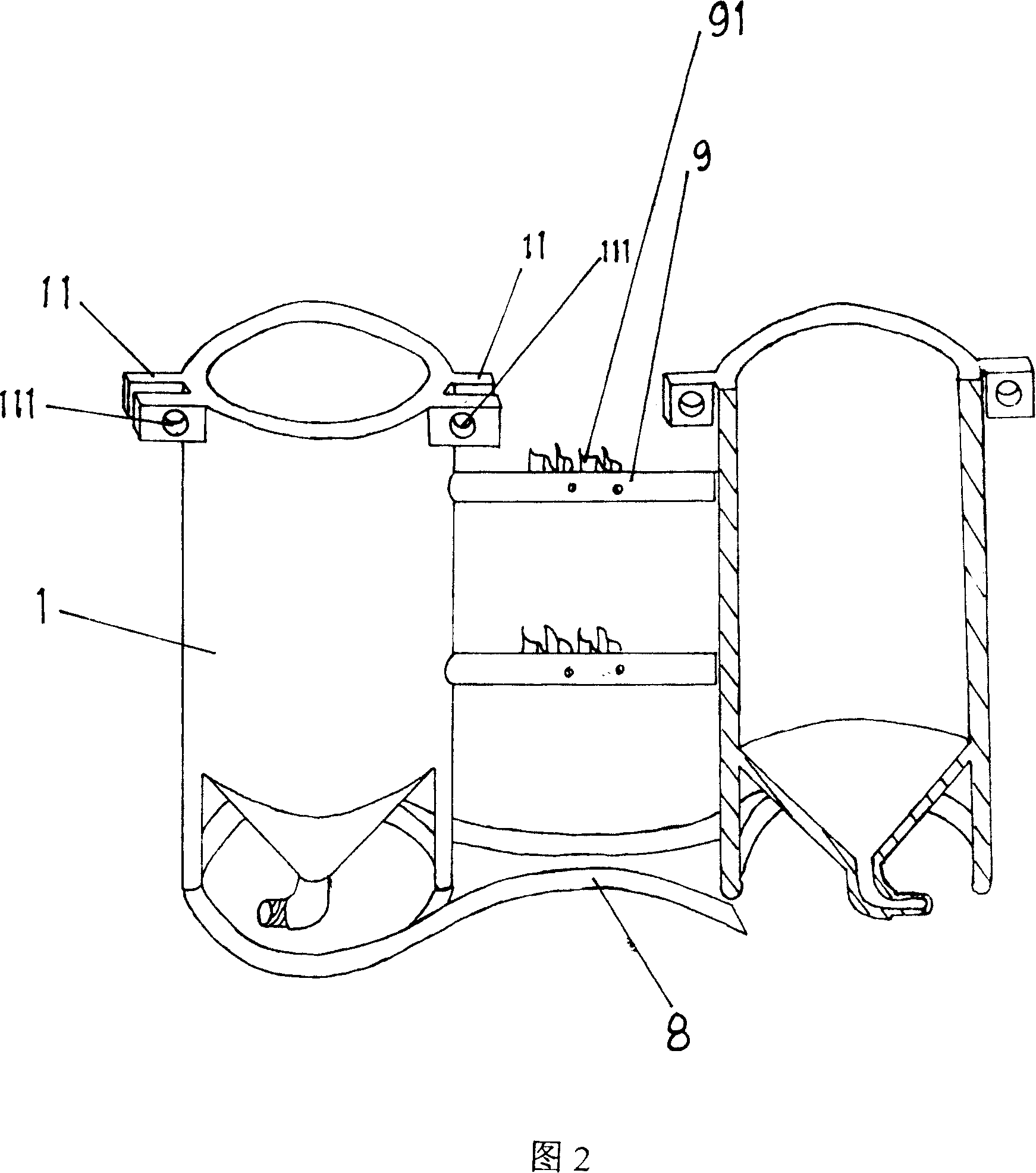

[0013] Please refer to Fig. 1 and shown in Fig. 2, the present invention can be used alone, and can also be used when two are connected together. When the two are connected together for use, a conjoined base 8 is provided, and two barrels 1 are placed on the conjoined base. 8, the strap 3 is a conjoined strap, and a nozzle placement rod 9 is arranged between the two barrels 1, and a clip 91 for clamping the nozzle 6 is arranged on the nozzle placement rod 9.

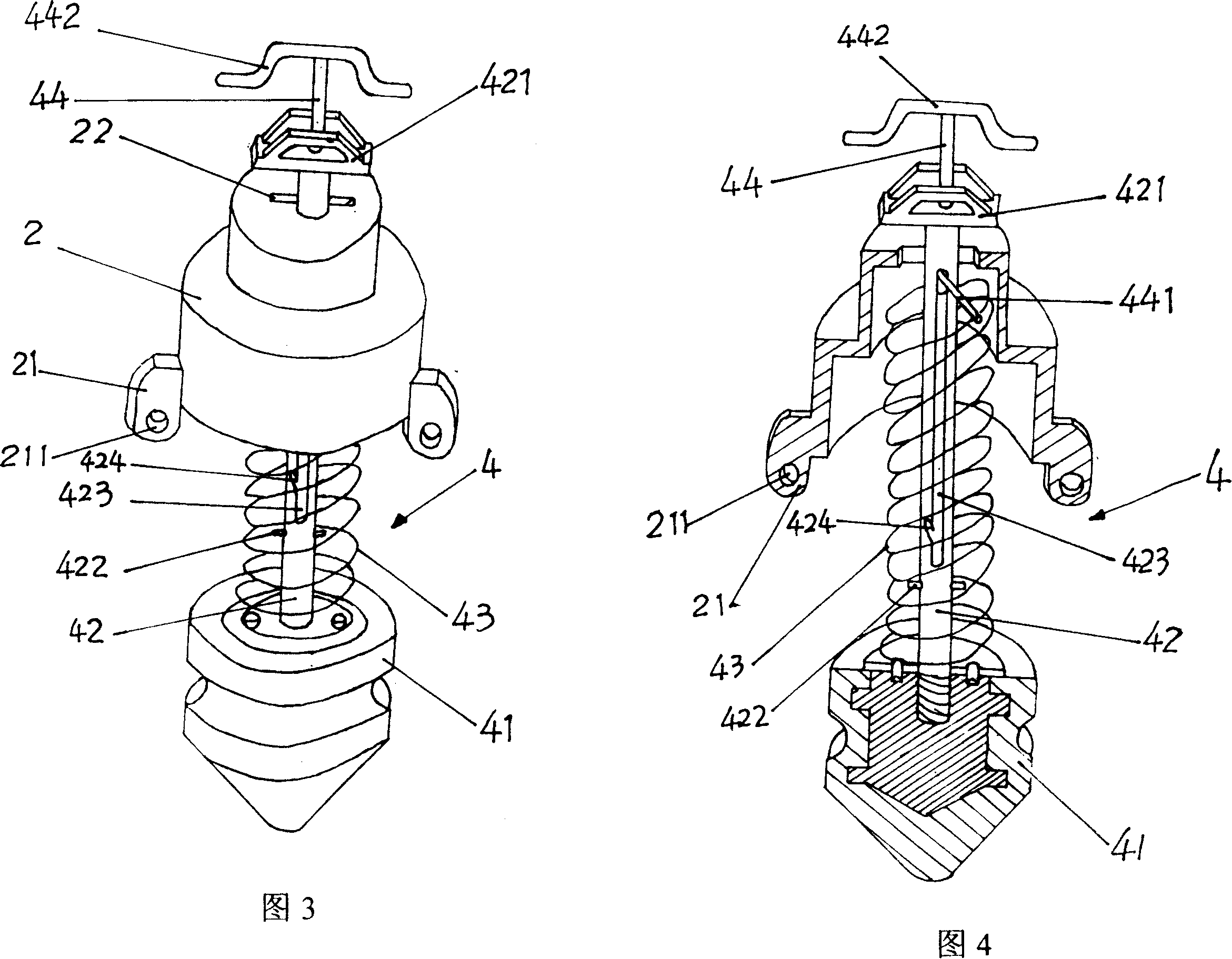

[0014] Please refer to Fig. 1, Fig. 2, Fig. 3, and Fig. 4, the present invention includes a barrel body 1, a cover 2, a strap 3, a pressurizing device 4, a liquid outlet pipe 5, a spray rod 7 and a nozzle 6, wherein, The pressurizing device 4 is arranged in the barrel body 1, the strap 3 is fixed outside the barrel body 1, one end of the liquid outlet pipe 5 is connected with the bottom of the barrel body 1, and the other end of the liquid outlet pipe 5 is connected with the nozzle 6 through the spray rod 7 , the spray r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com