Machine for shredding corn stalk, ploughing silage stubble and returning it to field

A technology for corn stalks and silage, which is applied in cutters, harvesters, cutting equipment, etc., can solve the problems of no silage, packing and filling functions, and can not reach, and achieve light weight, high production efficiency, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

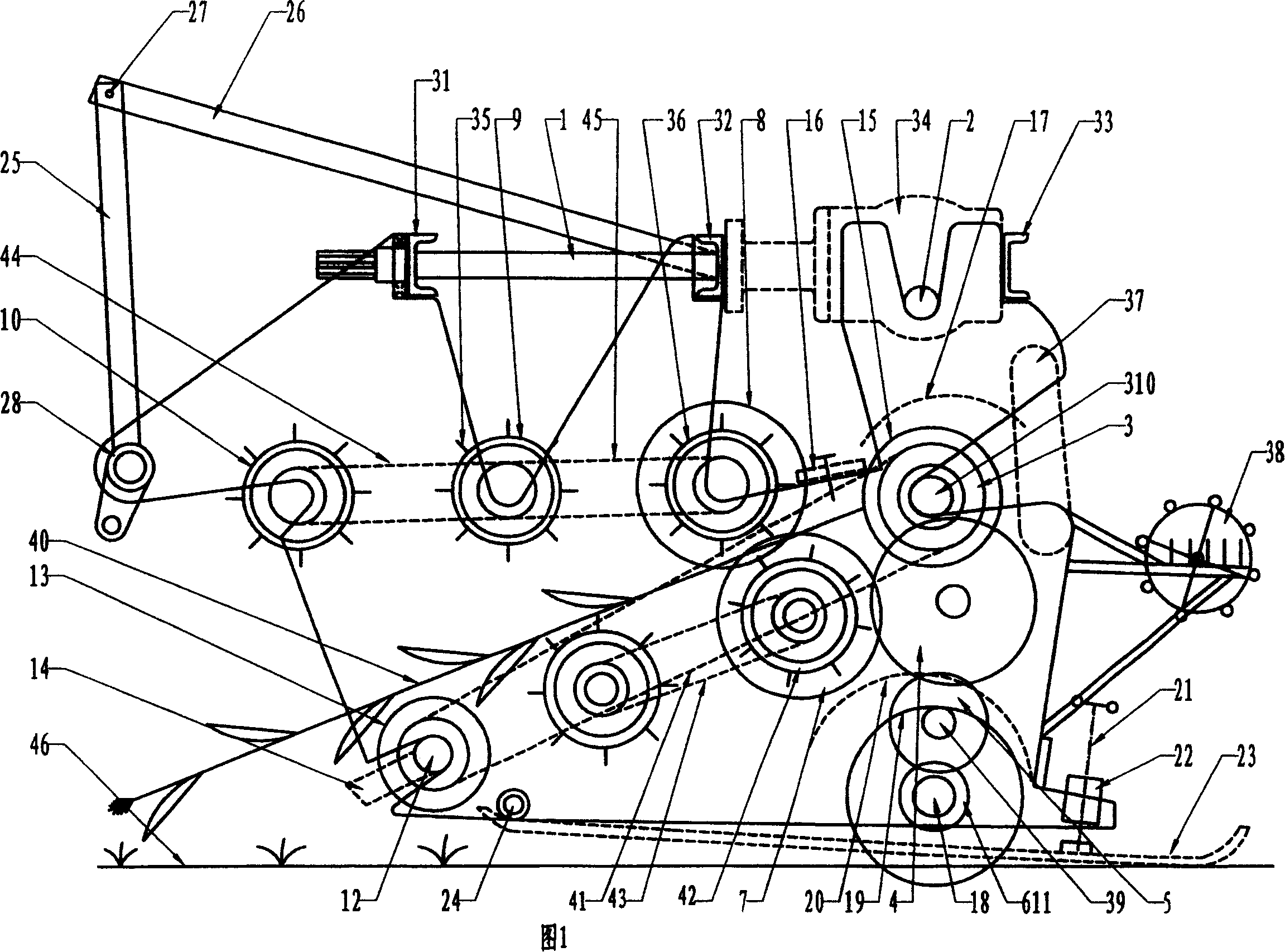

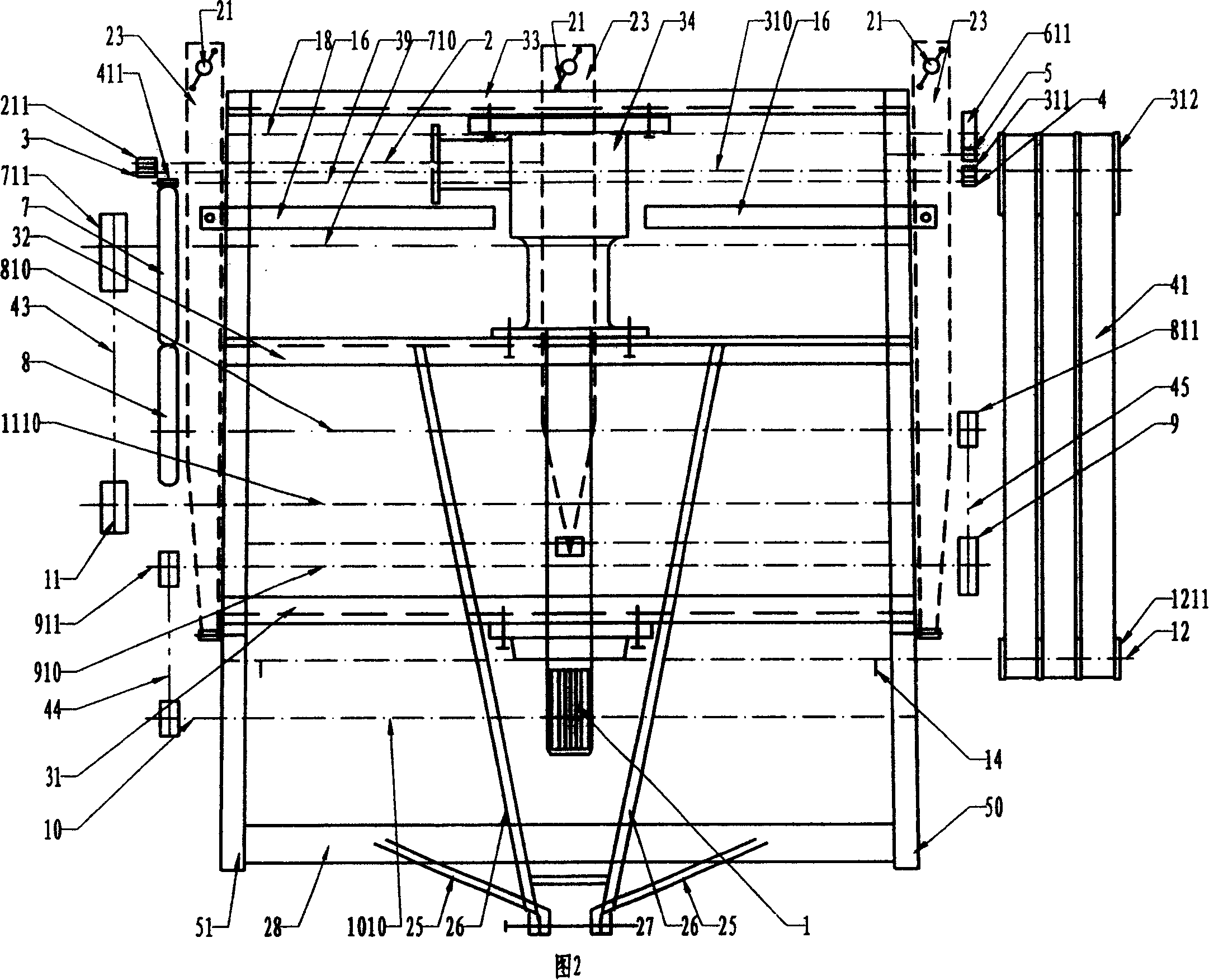

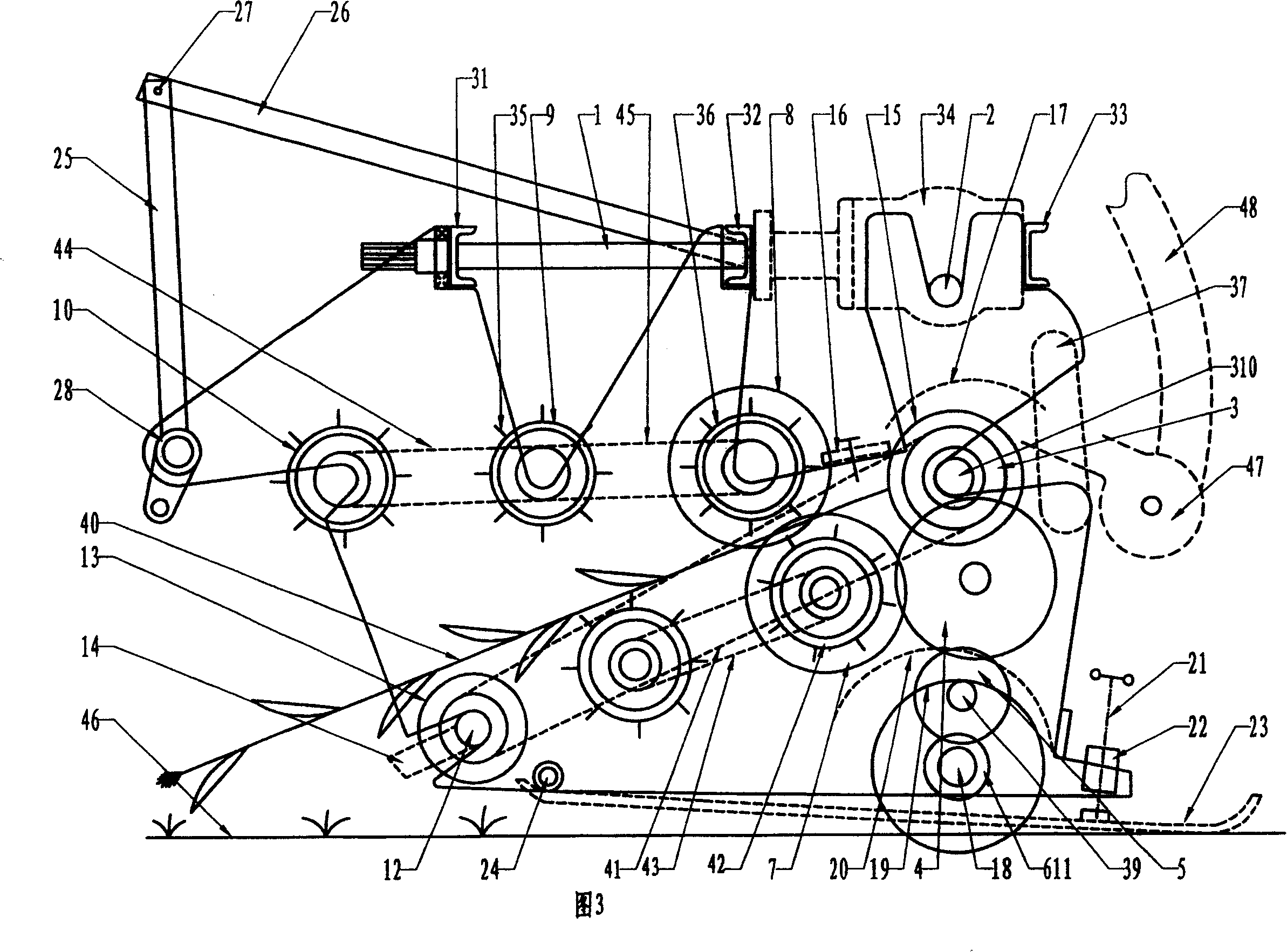

[0031] As shown in Figure 1 and Figure 2, the corn stalk chopped silage stubble returning machine includes a frame, a straw cutting mechanism, a feeding system, a cutting and crushing mechanism, a silage mechanism, and a stubble killing mechanism.

[0032] The longitudinal drive shaft 1 is connected to the gearbox 34 through the longitudinal drive shaft frame 31 fixed on the frame and the gearbox front frame 32. The output half shaft 2 of the gearbox 34 is provided with a gear 211, which is connected to the straw chopper. The gear 3 on the shaft 310 meshes to transmit power to the lower straw chopper shaft 310. The transmission 34 is supported by the transmission front frame 32 and the transmission rear frame 33.

[0033] The other end of the straw chopper shaft 310 is provided with a gear 311 which meshes with the transmission gear 4 at one end of the transmission shaft 39, and the other end of the transmission shaft 39 is provided with a gear 411 which is connected to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com