Mixed excitation switch reluctance motor

A technology of switched reluctance motor and mixed excitation, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., and can solve the problems of low performance-to-volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

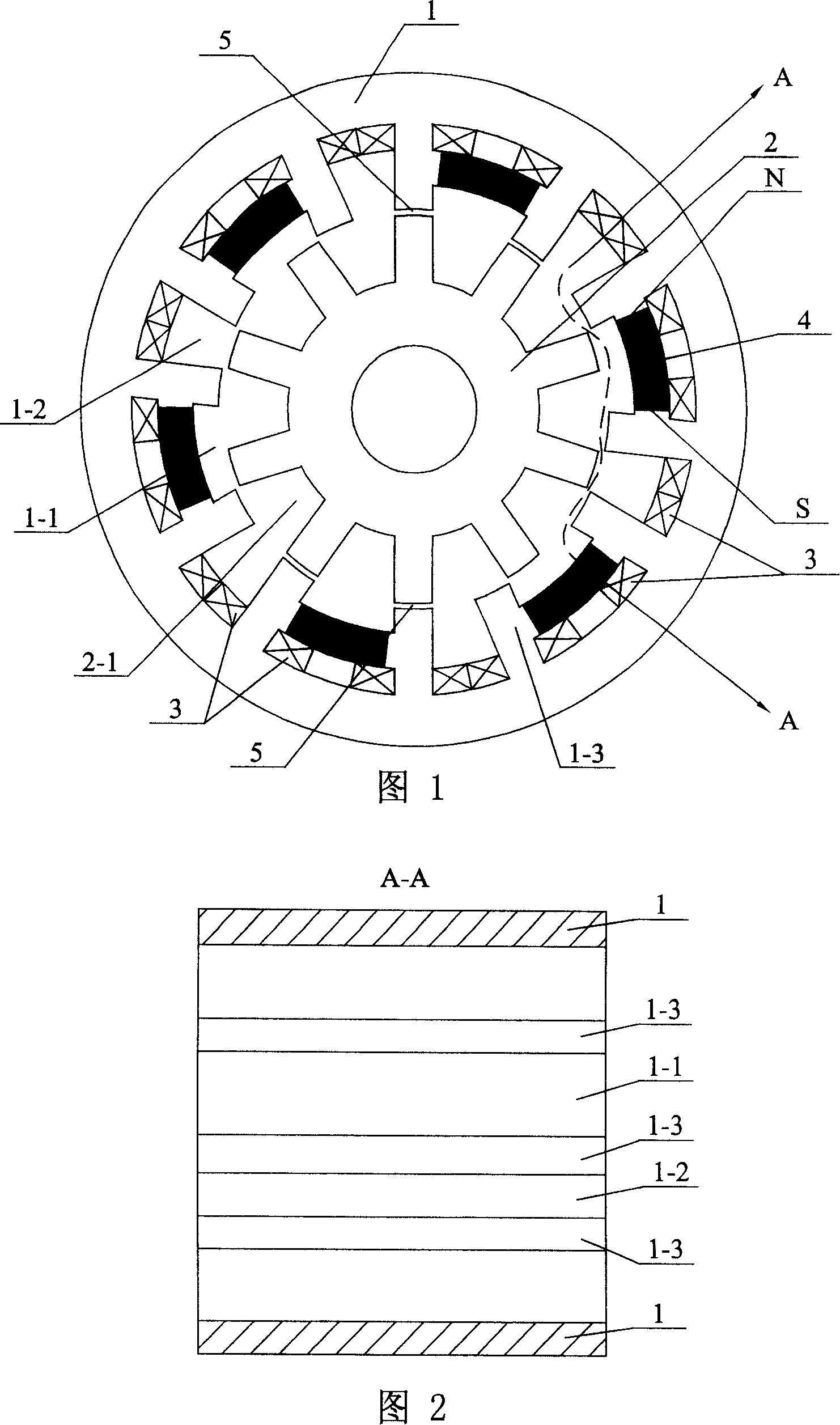

[0005] Specific embodiment 1: This embodiment is described in conjunction with Fig. 1 and Fig. 2. This specific embodiment consists of a stator 1, a rotor 2, an excitation winding 3, and a permanent magnet 4; the stator 1 is a cylindrical sleeve made of a magnetically conductive material, and the inner There are a plurality of wide slots 1-1 and narrow slots 1-2 on the cylindrical surface, the length direction of the wide slots 1-1 and narrow slots 1-2 is parallel to the axis line of the stator 1 and runs through the inner cylindrical surface of the stator 1, The wide slots 1-1 and the narrow slots 1-2 are evenly spaced from each other, and the thickness of the pole body 1-3 between the wide slots 1-1 and the narrow slots 1-2 is equal; the rotor 2 is a cylinder made of magnetically conductive material A plurality of slots 2-1 are evenly opened on the outer cylindrical surface of the rotor 2, and the length direction of the slots 2-1 is parallel to the rotation axis of the rotor...

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the stator 1 is made of superimposed silicon steel sheets, and the rotor 2 is made of superimposed silicon steel sheets. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Embodiment 3: The direction of the magnetic force lines generated by the excitation winding 3 in this specific embodiment is consistent with the direction of the magnetic force lines of the permanent magnet 4 . Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com