Light conducting plate and back light module

A technology of backlight module and light guide plate, applied in the directions of light guide, optics, optical components, etc., can solve the problems of high cost, disadvantageous precision machining, difficult multi-layer structure processing, etc., and achieve the effect of simplifying the system and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The light guide plate and the backlight module of the present invention will be further described in detail with reference to the accompanying drawings and multiple embodiments.

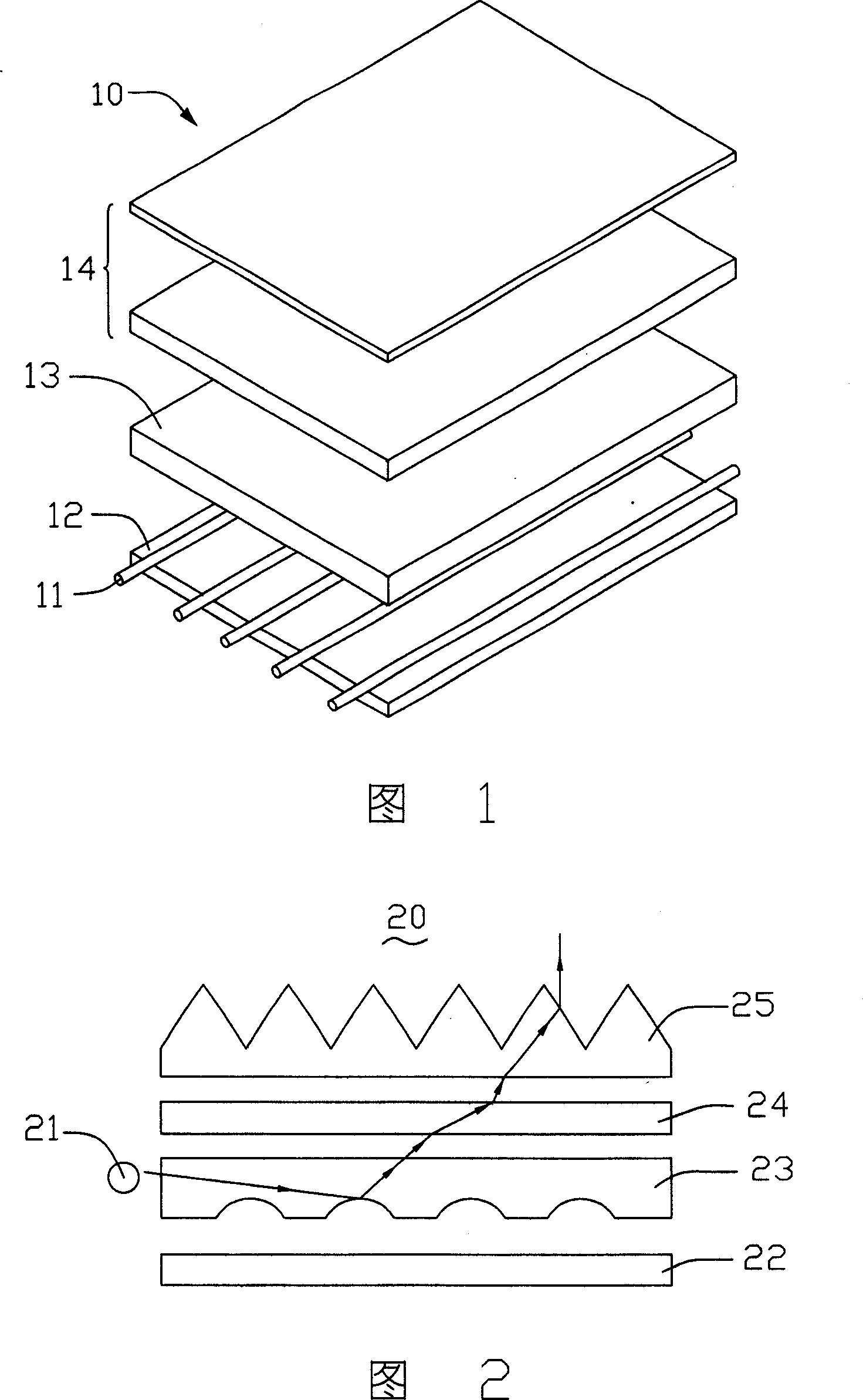

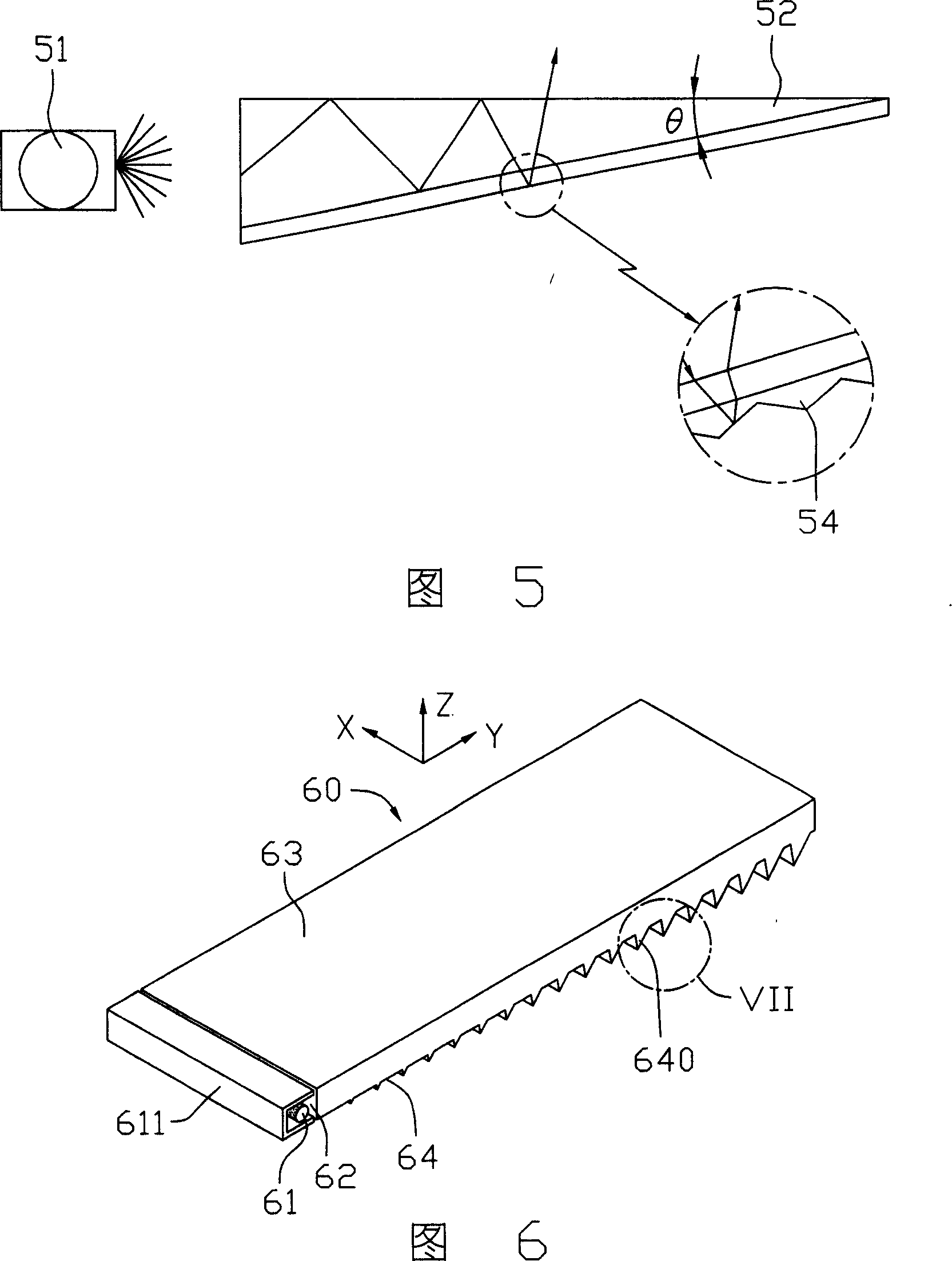

[0034] Please refer to FIG. 6 and FIG. 7 together. The first embodiment of the present invention provides a 14.1-inch flat light guide plate 60, including an incident surface 62, an outgoing surface 63, a reflective surface 64 opposite to the outgoing surface 63, and The other three sides (not labeled). Wherein, the incident surface 62 is formed on a side surface of the light guide plate 60 adjacent to the side cold cathode tube 61 . The emitting surface 63 is formed on the top surface of the light guide plate 60 . The reflective surface 64 is formed on the bottom surface of the light guide plate 60 . The reflective surface 64 is also formed with several V-shaped microstructures 640 protruding from the light guide plate 60 along the direction away from the outgoing surface 63 . The value ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com