Variable volume meter body

A meter and variable volume technology, applied in the direction of volume measurement, measurement capacity, volume/mass flow generated by mechanical effects, etc., can solve the problems of inaccurate measurement, small driving force, non-measurement, etc., and achieve reduced pressure loss and reliable The effect of folding and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

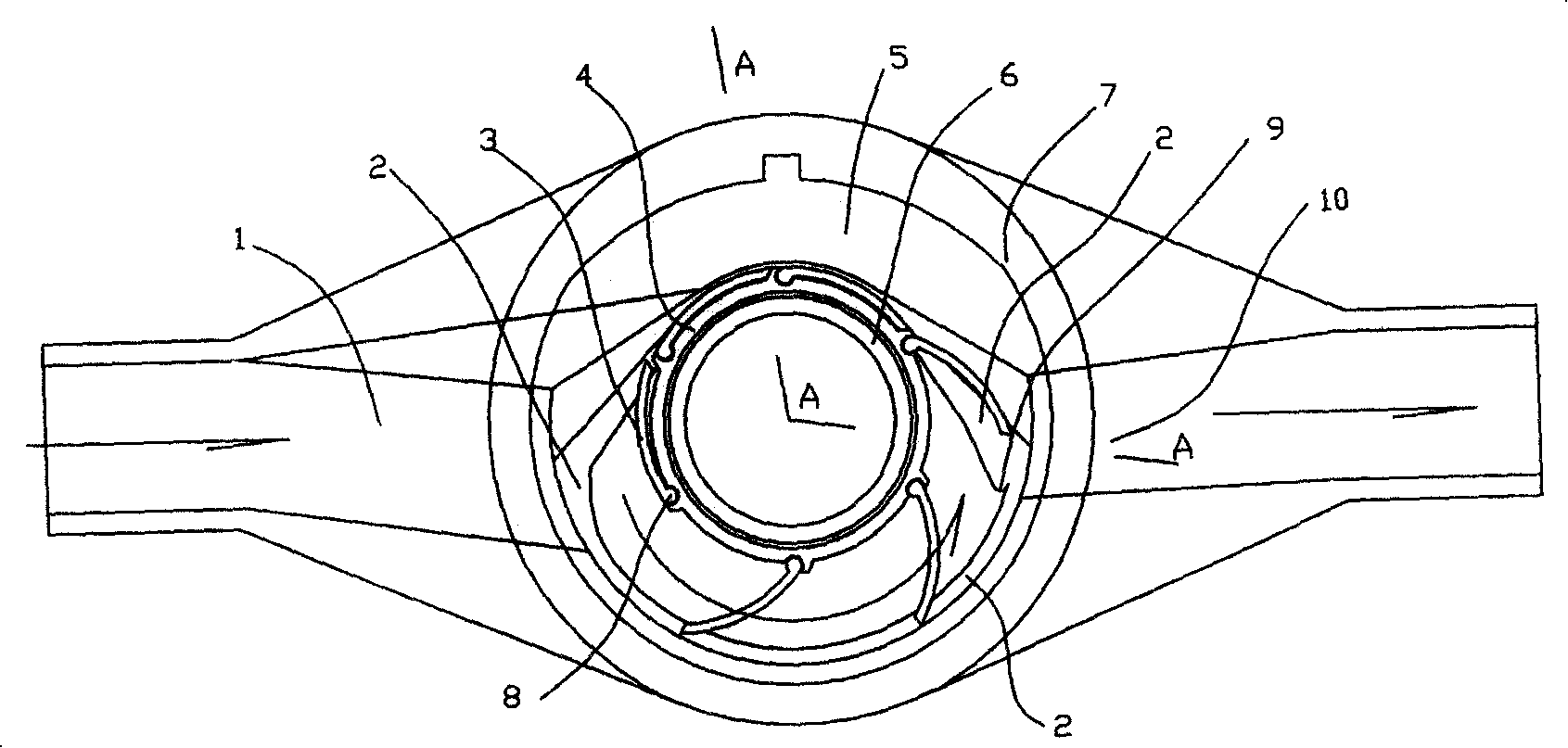

[0023] Such as figure 1 , 2 As shown, the meter body of this kind of variable volume meter has an inner cavity bushing 5 made of non-toxic wear-resistant plastic embedded in the meter body shell 7, and the inner cavity of the bushing 5 constitutes the inner cavity of the meter. An impeller device is installed in the middle of the inner cavity of the meter. The key point is that the impeller device is a deformable impeller device. The deformable impeller device is composed of a rotor body 4 in the middle and six blades 3 arranged around the rotor body in turn. The heads of each blade 3 are connected to the The rotor body 4 is rotated and assembled together, and each blade body can swing around the head to open and close. The ring around the deformable impeller device is bounded by the fluid inlet 1 and the fluid outlet 10, and the part of the blade 3 passing from the fluid inlet to the fluid outlet The ring road is a metering channel, and the part of the ring road where the bl...

Embodiment 2

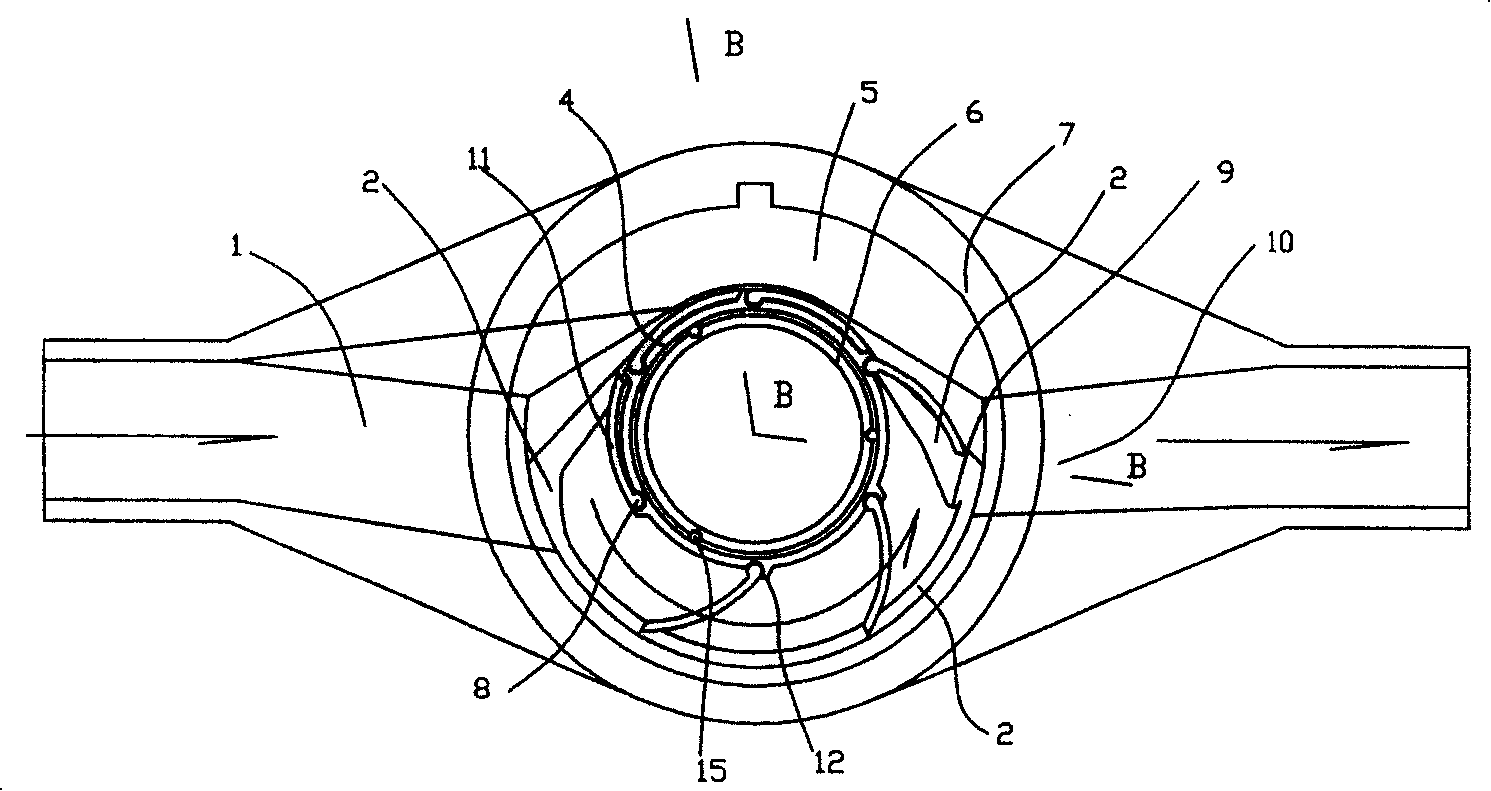

[0025] Such as image 3 , 4 As shown, the difference between the meter body of this kind of variable volume meter and Embodiment 1 is that, firstly, all the blades are set as limiting blades 11, and there is a gap between the head of the limiting blades 11 and the corresponding assembly part of the rotor body 4. The structure 12 for limiting the opening angle of the limiting vane, the opening angle of the limiting vane 11 is between 20° and 90°, and the edge of the tail part is in clearance fit with the inner cavity wall of the meter when it rotates in the metering channel. Secondly, three rolling bearings 15 parallel to the rotation axis of the rotor body are evenly assembled between the sleeve shaft 6 and the rotor body 4 .

Embodiment 3

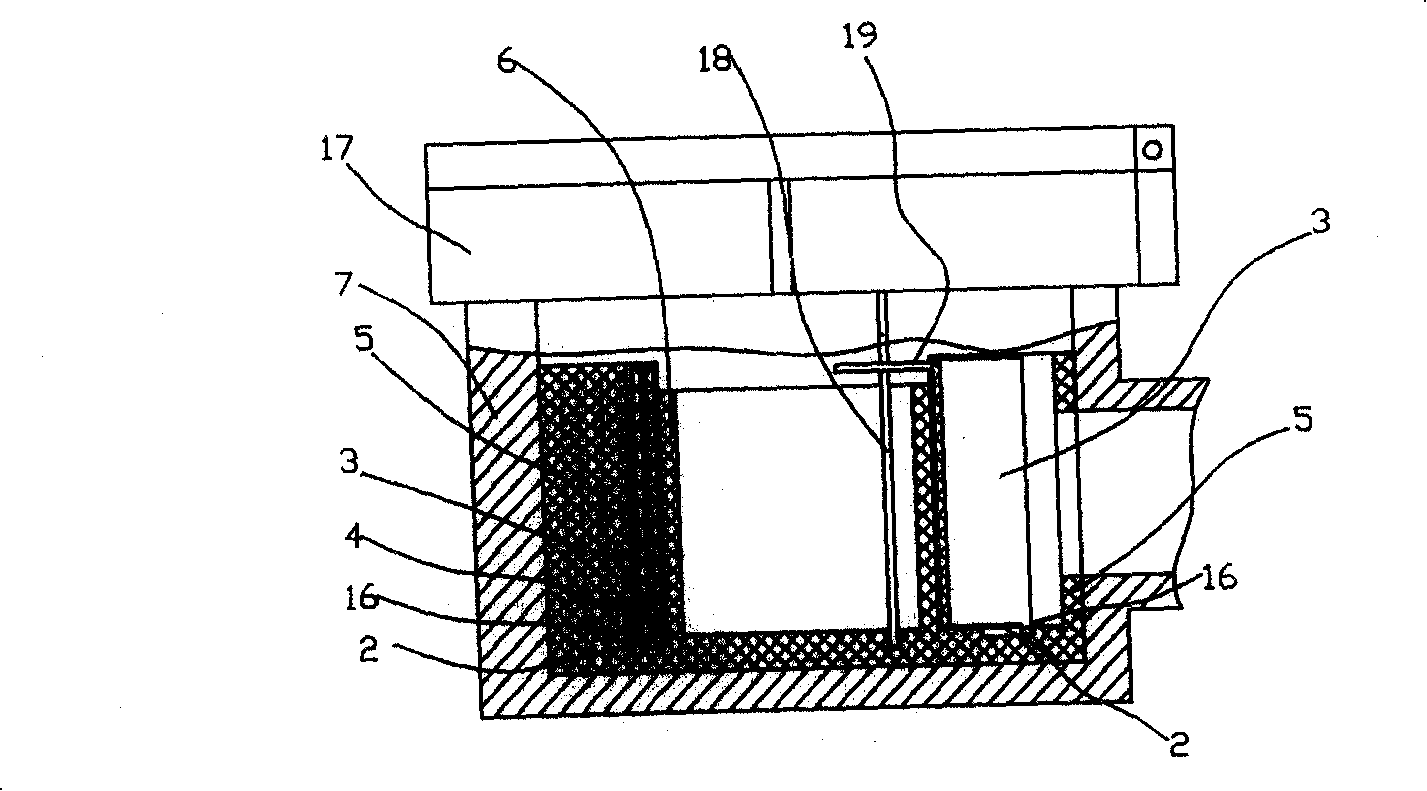

[0027] Such as Figure 5 , 6As shown, the meter body of this kind of variable volume meter has an inner cavity bushing 5 made of non-toxic wear-resistant plastic embedded in the meter body shell 7, and the inner cavity of the bushing 5 constitutes the inner cavity of the meter. An impeller device is installed in the middle of the inner cavity of the watch, the key is that the impeller device is a deformable impeller device, and the deformable impeller device consists of the rotor body 4 in the middle and the six blades (which can also be appropriately increased to eight blades) surrounded by the rotor body 4. or ten), each blade head and rotor body 4 are rotated and assembled together, and each blade body can swing around the head to open and close, and the ring around the deformable impeller device is bounded by the fluid inlet 1 and the fluid outlet 10, and the blades The part of the ring that passes from the fluid inlet to the fluid outlet is the metering channel, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com