Agitator shaft end seal failure diagnosis apparatus

A fault diagnosis device and shaft end sealing technology, which is applied in the direction of measuring devices, fluid tightness testing, machine/structural component testing, etc., can solve problems such as damage to shaft end seals, mud intrusion, worn spindles, etc., and reach maintenance intervals Long-term, large economic loss, and the effect of large economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

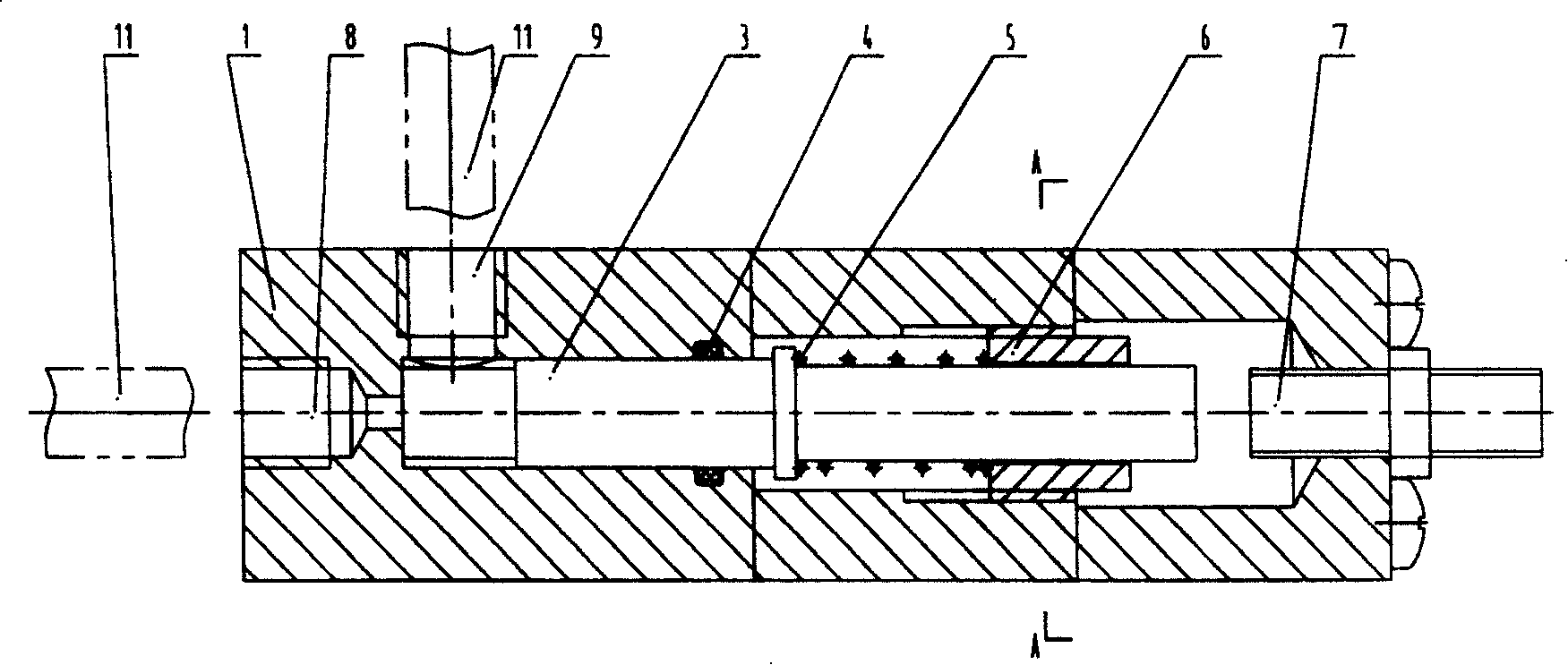

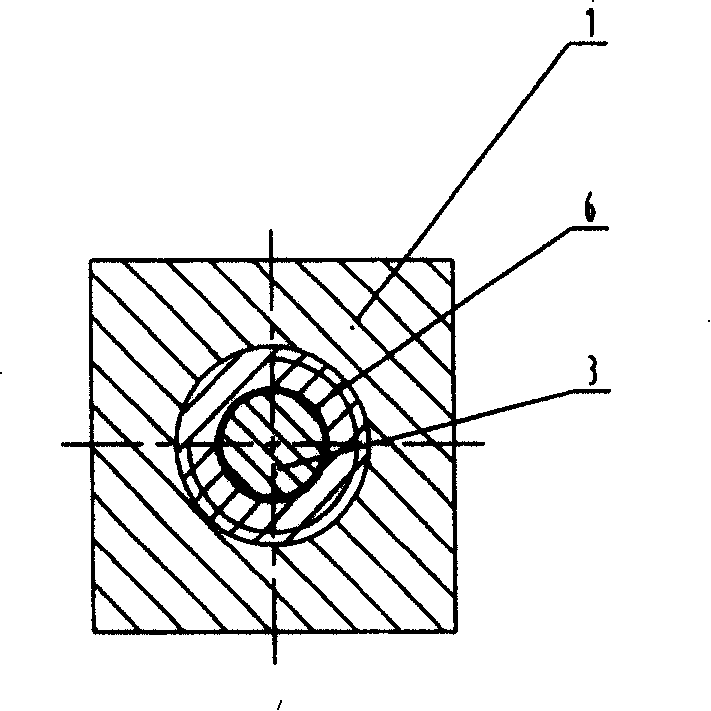

[0021] Embodiment 1: as figure 1 and figure 2 As shown, the mixer shaft end seal fault diagnosis device in the present invention is mainly used for single-shaft and double-shaft concrete mixers, and it is installed on the butter lubrication pipe 11 of the concrete mixer. The detection device includes a sliding body 1, a sliding rod 3, a sealing ring 4, a spring 5, an adjusting nut 6 and a sensor 7. The sliding rod 3, the sealing ring 4, the spring 5 and the adjusting nut 6 are all arranged in the sliding body 1. The sliding body 1 is provided with an oil inlet 8 and an oil outlet 9 which communicate with the grease lubricating pipeline 11, and the oil inlet 8 and the oil outlet 9 communicate and are not in a straight line. One end of the sliding rod 3 is connected with the oil inlet 8, and the oil inlet 8 can be blocked when it is pressed, and the other end is connected with the adjusting nut 6, and a sealing ring 4 is provided between the sliding rod 3 and the sliding body ...

Embodiment 2

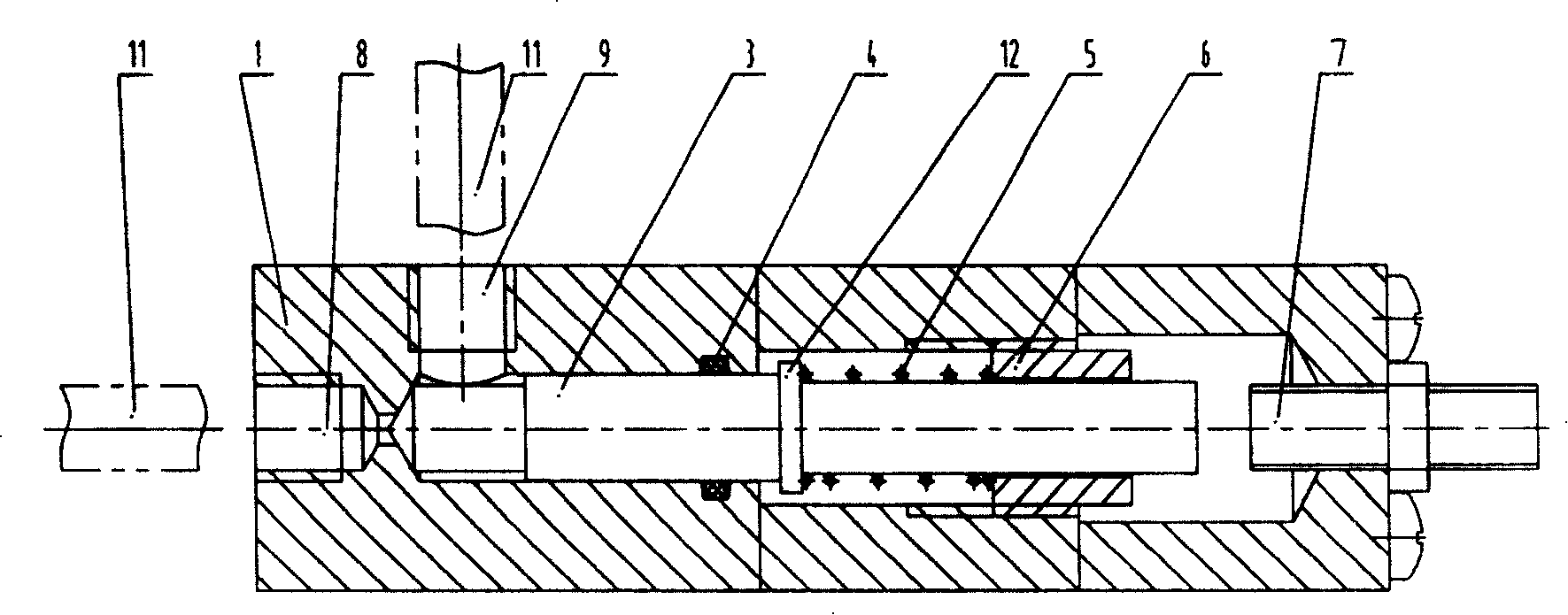

[0022] Embodiment 2: as image 3 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that the contact surface on the slide rod 3 and the connection end of the oil inlet 8 is a conical surface, and the conical end surface can make the slide rod 3 better contact with the oil inlet port 8. The oil inlet 8 is connected to each other, and when the slide rod 3 is in the state of blocking the oil inlet 8, the sealing performance is better. By analogy, the structure of the present invention is not limited to the structure of the embodiment, and the contact surface on the sliding rod 3 and the connection end of the oil inlet 8 can also be in other shapes.

[0023] Working principle: The working principle of embodiment 1 and embodiment 2 is basically the same. They both adopt the scheme of detecting whether there is butter flowing into the shaft end seal. The detection device of the present invention is added above, and the pressure...

Embodiment 3

[0024] Embodiment 3: as Figure 4 As shown, the mixer shaft end seal fault diagnosis device in the present invention is mainly used for single-shaft and double-shaft concrete mixers, and it is installed on the butter lubrication pipe 11 of the concrete mixer. The detection device includes a sliding body 1, a push block 2, a sliding rod 3, a sealing ring 4, a spring 5, an adjusting nut 6 and a sensor 7. The sliding rod 3, the sealing ring 4, the spring 5 and the adjusting nut 6 are all arranged on the sliding body 1. Inside. The sliding body 1 is provided with an oil inlet 8 and an oil outlet 9 which communicate with the grease lubricating pipeline 11, and the oil inlet 8 and the oil outlet 9 communicate and are not in a straight line. One end of the slide bar 3 is connected with the oil inlet 8, and the other end is connected with the adjustment nut 6, and a sealing ring 4 is arranged between the slide bar 3 and the slide body 1 to prevent the butter from infiltrating. A pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com