Torque vibration damper

A technology of torsional vibration and damper, applied in vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve problems such as fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

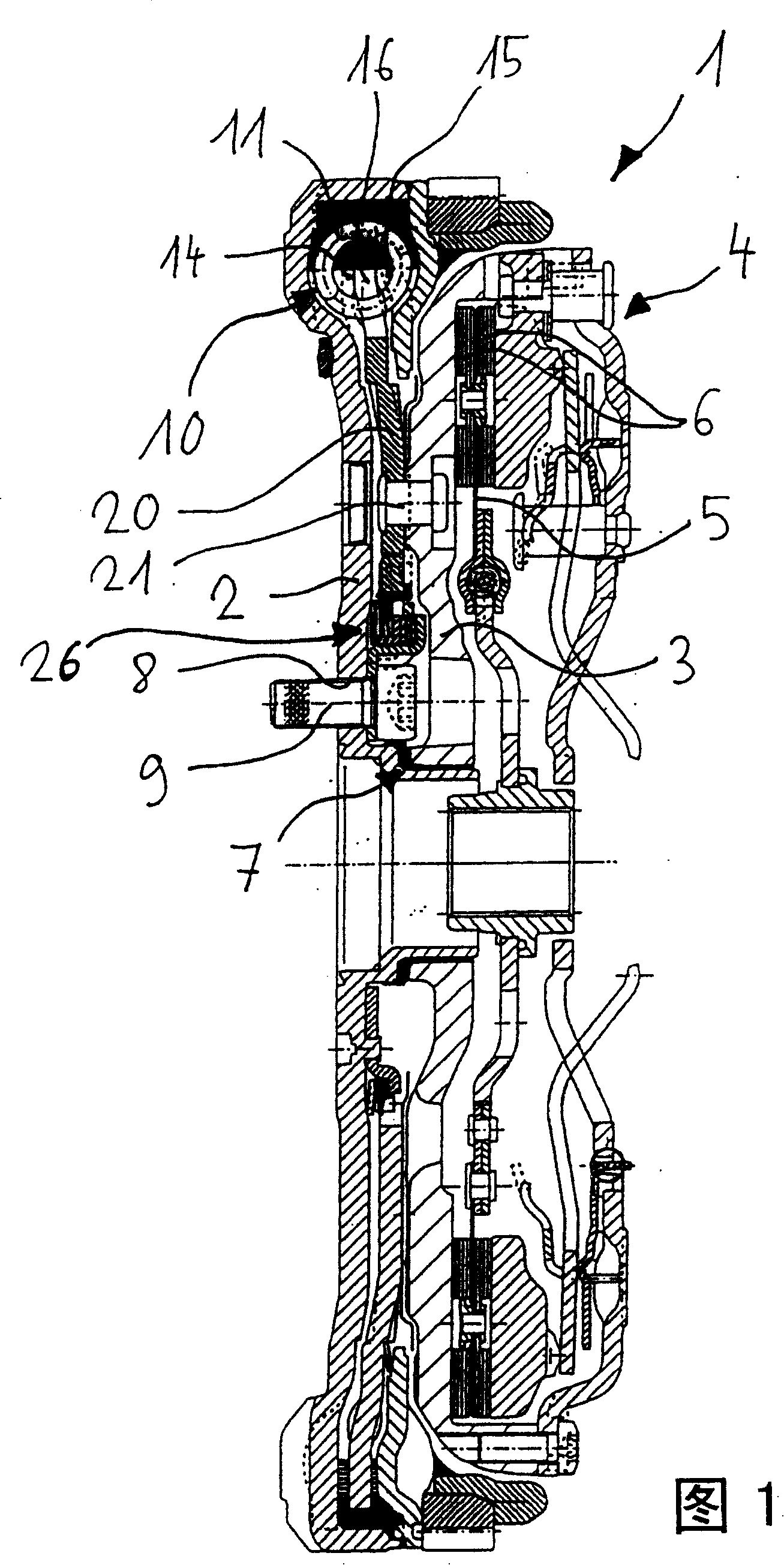

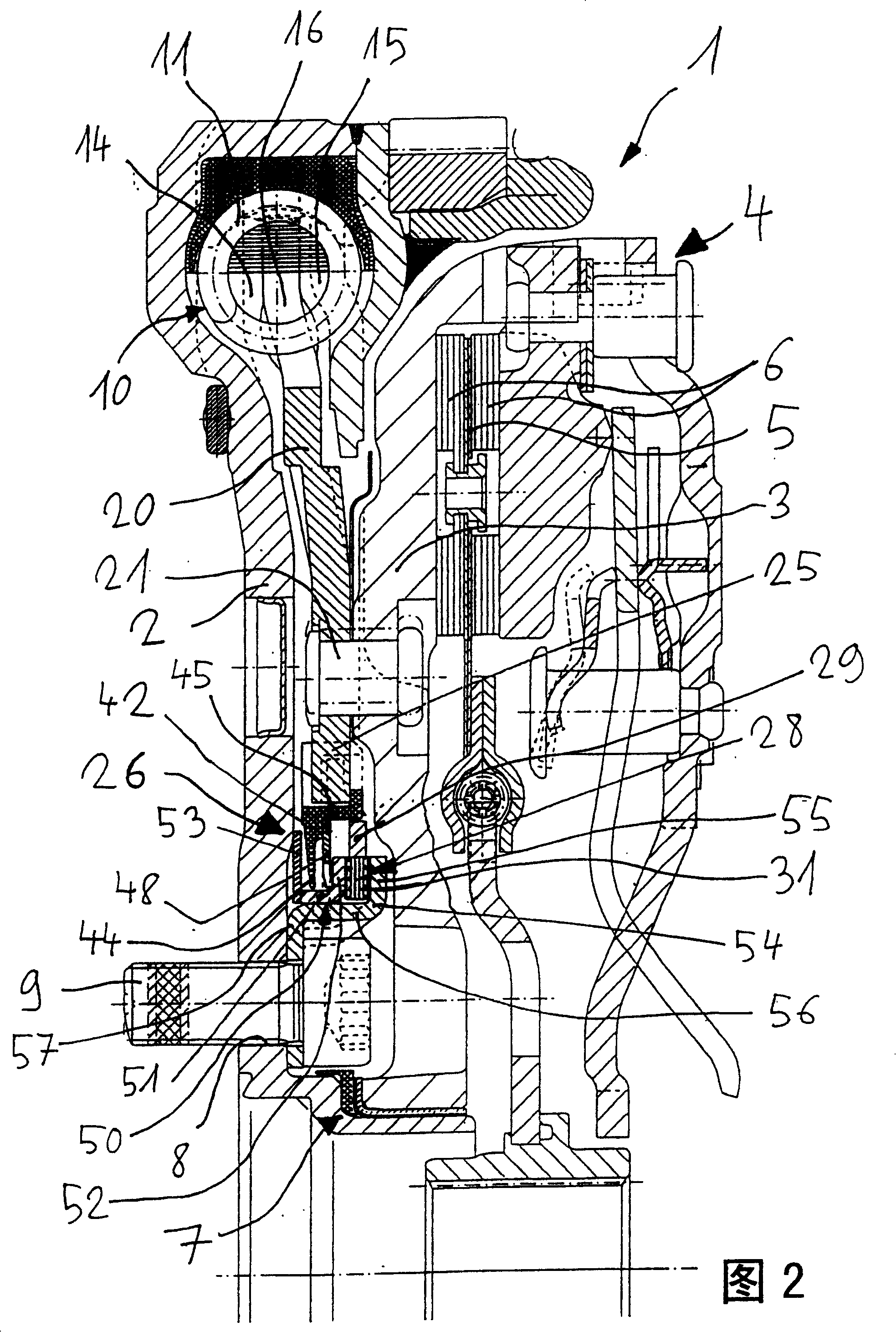

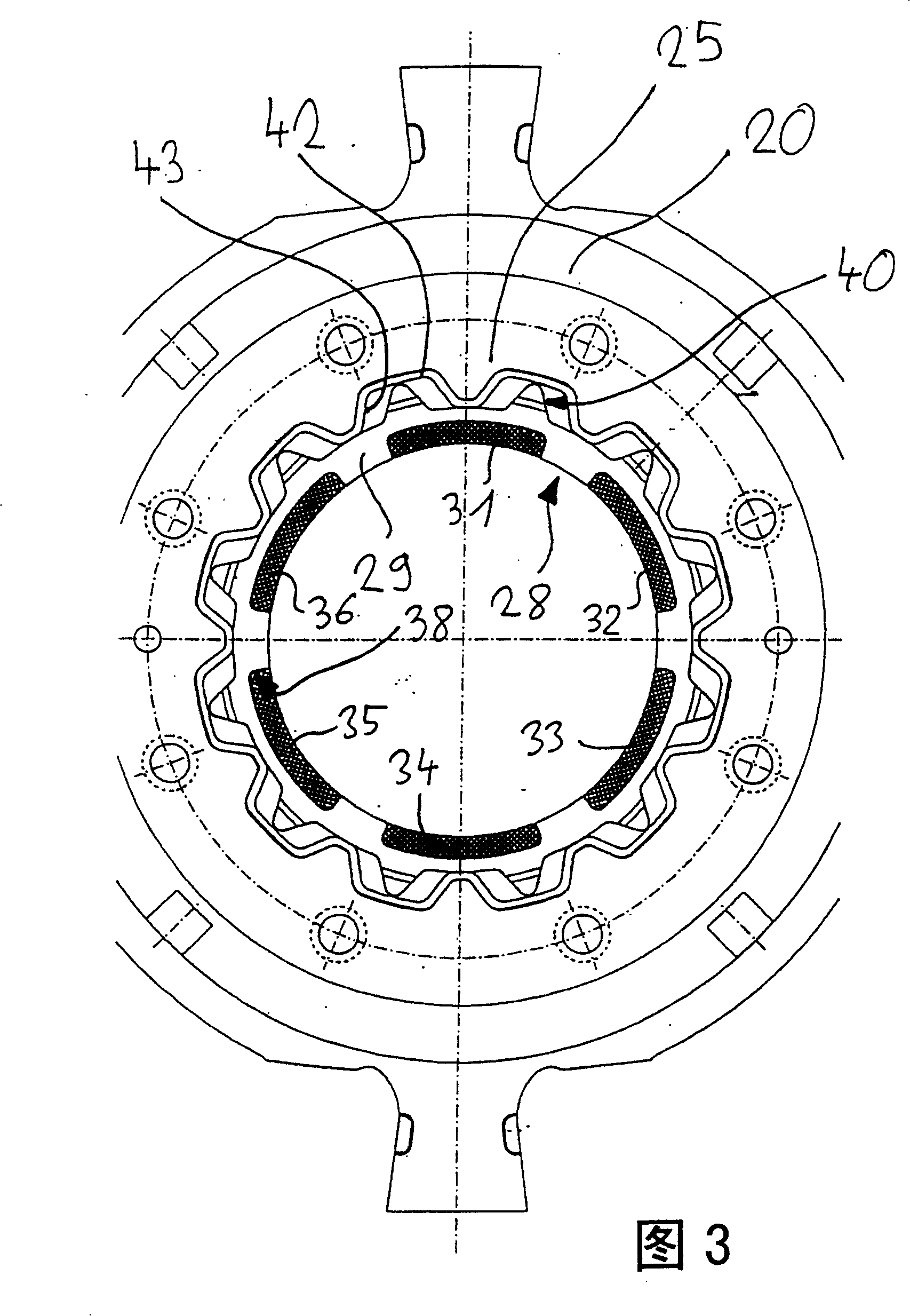

[0027] The torsional vibration damper shown in Figure 1 constitutes a split flywheel 1 having a first or primary flywheel mass 2 and a second or secondary flywheel mass 2 fixable on the output shaft (not shown) of an internal combustion engine. Grade flywheel quality 3. A friction clutch 4 can be attached to the second flywheel mass 3 with a clutch disk 5 interposed therebetween, by means of which a (also not shown) transmission input shaft can be engaged or disengaged. On the clutch disc 5 are mounted friction linings 6 which are loaded with pressure when the clutch is engaged. The function of the friction clutch 4 is assumed to be known and will therefore not be explained further.

[0028] The flywheel masses 2 and 3 are rotatably supported relative to one another via a support structure 7 which, in the illustrated embodiment, is arranged radially inside holes 8 for passing fixing screws 9 for The first flywheel mass 2 is mounted on the output shaft of the internal combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com