Industrial chemical reaction kettle

A chemical reaction kettle and industrial technology, applied in the chemical field of industry, can solve the problems of difficult thread rotation and large friction resistance, and achieve the effect of avoiding excessive deformation and avoiding irregular deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as Figure 1-Figure 5 Shown:

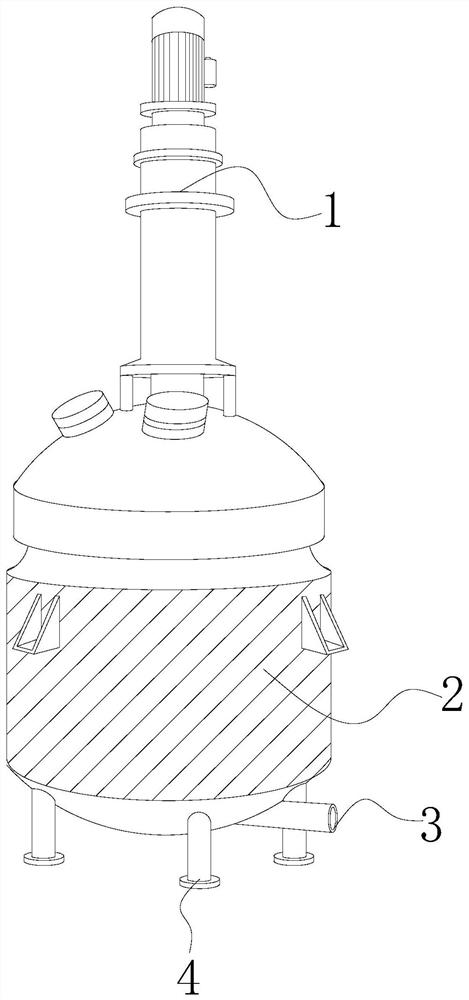

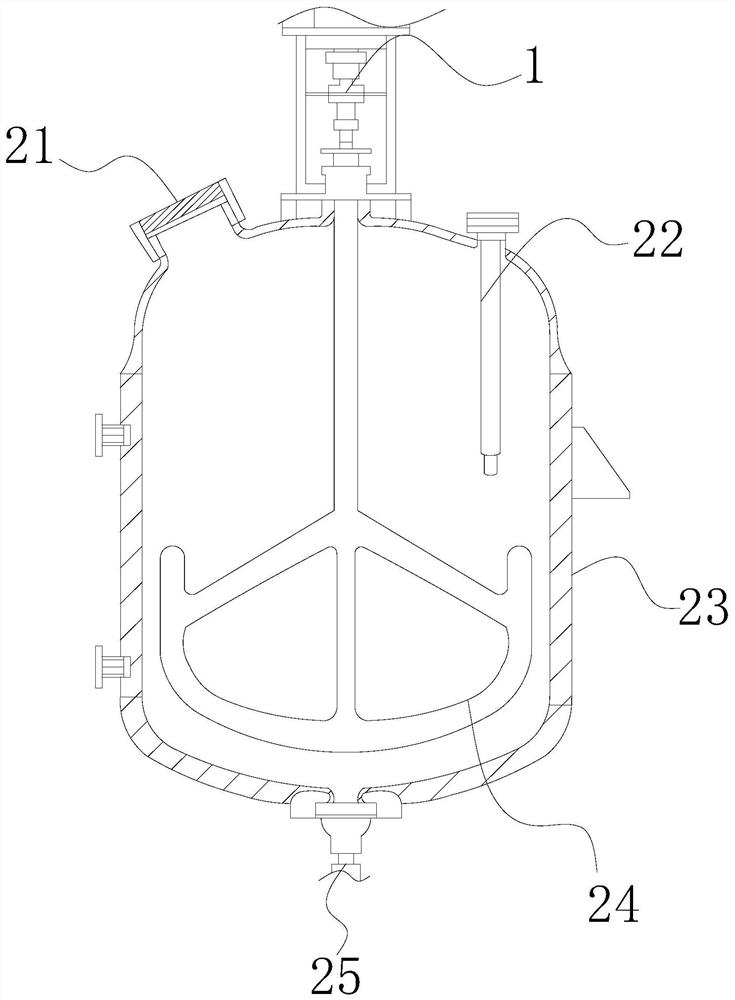

[0025] The present invention is an industrial chemical reaction kettle, its structure includes a motor 1, a reaction device 2, a flow pipe 3, and a support column 4, the motor 1 is embedded in the middle of the upper end of the reaction device 2, and the flow pipe 3 is installed in the reaction device 2 The lower end, the support column 4 is welded on the lower end of the reaction device 2, the reaction device 2 is provided with a closing mechanism 21, a detector 22, a reaction box 23, an agitator 24, and an outlet pipe 25, and the closing mechanism 21 is installed in the reaction box 23 on the left upper end, the detector 22 runs through the upper right end of the reaction box 23, the outlet pipe 25 is located on the same central axis as the agitator 24, and the upper end of the agitator 24 is embedded in the middle lower end of the motor 1. The outlet pipe 25 is installed on the inner side of the flow pipe 3, and the agitator 24 is...

Embodiment 2

[0032] Such as Figure 6-Figure 7 Shown:

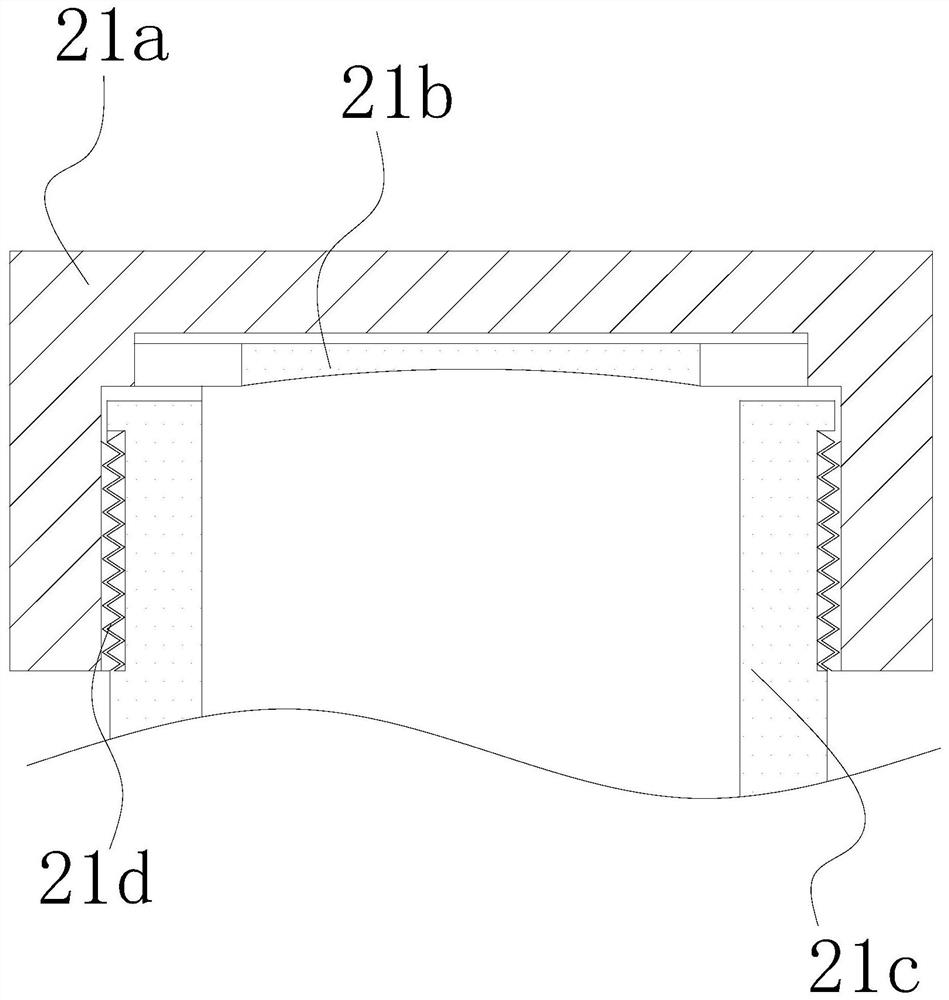

[0033] Wherein, the compression mechanism b4 is provided with a blocking mechanism w1, a shaping plate w2, a blocking plate w3, and a compression ball w4, the upper end of the blocking mechanism w1 is attached to the lower end of the shaping plate w2, and the compression ball w4 is engaged with the blocking plate w3 On the upper surface, the lower end of the blocking plate w3 is embedded and fixed on the upper end of the shaping plate w2, and the outer side of the shaping plate w2 is installed on the inner side of the friction mechanism b5. The shaping plate w2 is made of sponge material and has the characteristics of strong deformation effect. The blocking plate w3 is made of plastic and has a strong bending effect, so that the blocking mechanism w1 is pressed against the shaped plate w2 by force, so that the blocking plate w3 bends and moves toward the inner side of the closing cover 21a, thereby compressing the ball w4 to block the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com