Two stage control method for wetting leaf moisture regain temperature

A control method and temperature control technology, applied in electrical program control, comprehensive factory control, tobacco preparation, etc., can solve the problems of low control accuracy of leaf moistening and moisture recovery, poor product quality stability, etc., achieve improved temperature stability, and the method is simple and easy Line, high control precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

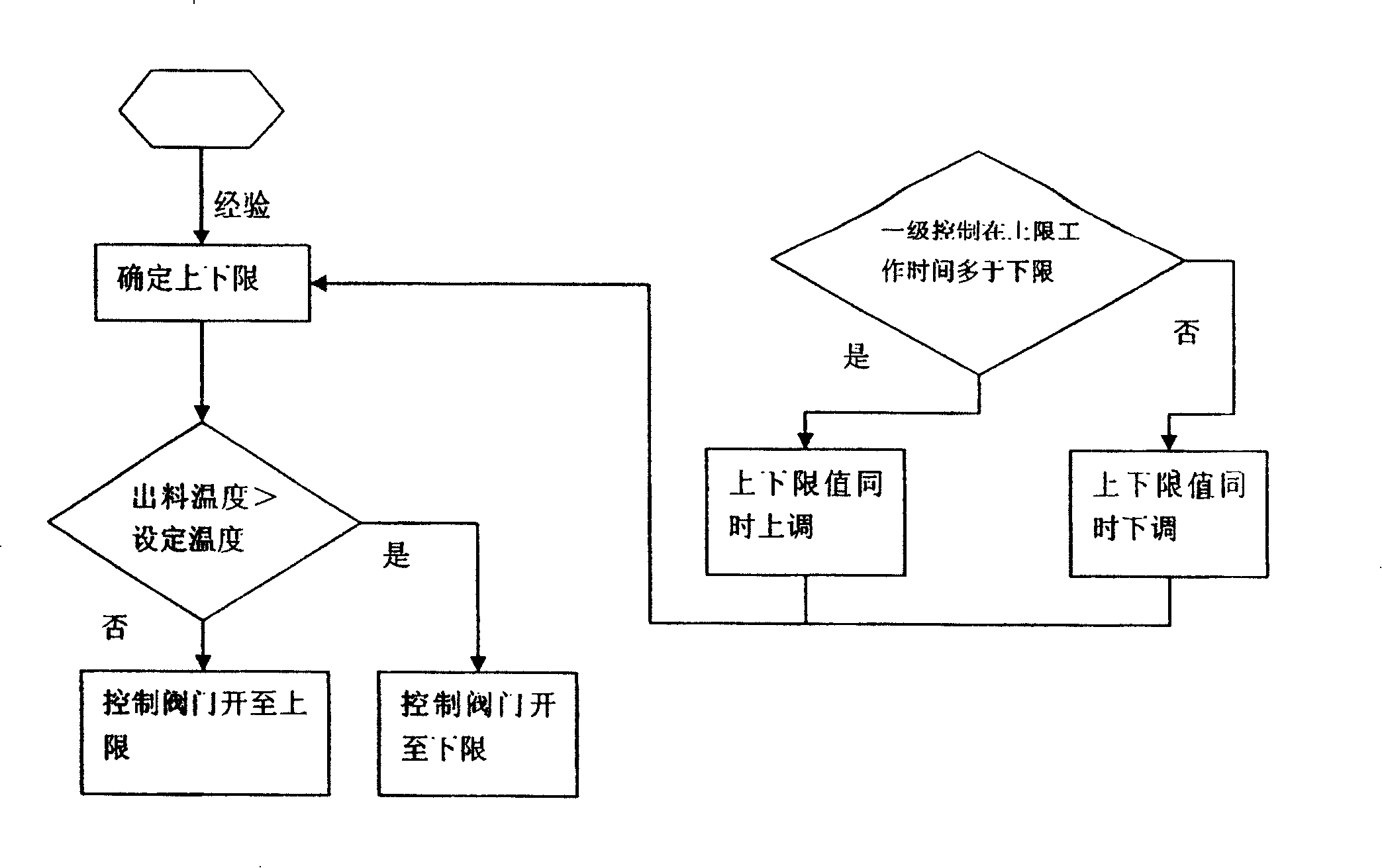

[0013] In Fig. 1, the present invention adopts two-stage serial temperature control mode to control the temperature at the place where the leaves are moistened.

[0014] First-level control: set the upper and lower limits of the valve opening (such as upper limit 70%, lower limit 50%). When the tobacco leaf discharge temperature does not reach the process set temperature, the PLC program controls the steam valve to open to the upper limit; when the tobacco leaf temperature exceeds the process set temperature, the PLC program controls the steam valve to drop to the lower limit. Due to the instantaneous fluctuation in the discharge of the moisture damper, the steam valve can be adjusted quickly according to the discharge temperature, so that the temperature of the damp damper can be stabilized, thereby stabilizing the temperature of the tobacco leaves.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com