Pure oxygen combustion system for multi-point precise control of rock wool melt temperature

A melt temperature and precise control technology, applied in the field of building insulation materials, can solve the problems of high acidity coefficient and insufficient melting strength, etc., achieve the effect of stable process temperature, increase fiber formation rate, and reduce product slag content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

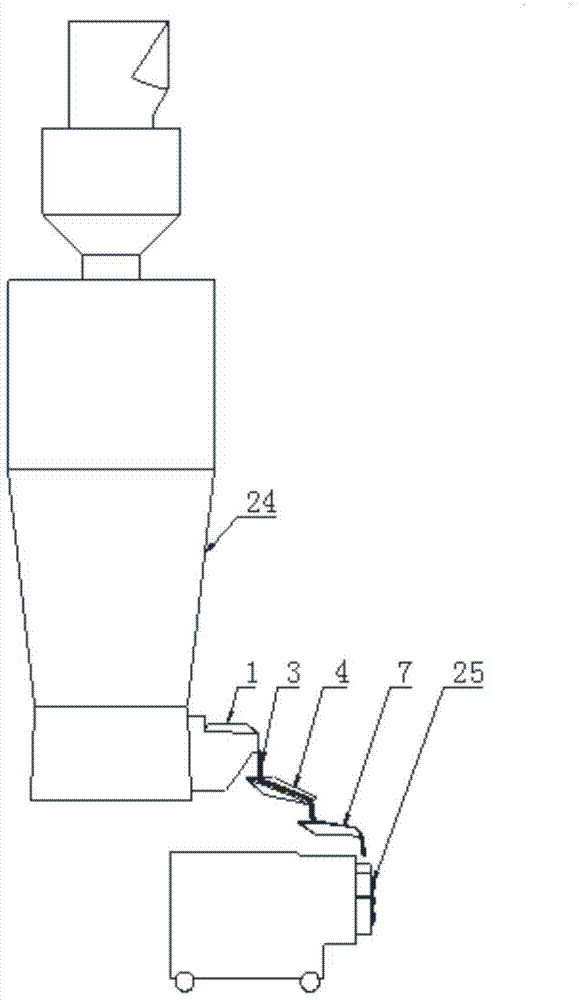

[0040] see figure 1 , a pure oxygen combustion system for multi-point precise control of rock wool melt temperature in this embodiment, including cupola 24, No. 1 active chute 4, No. 2 active chute 7 and centrifuge 25, No. 1 active chute No. 4 and No. 2 movable chutes 7 are located between the siphon port 1 at the bottom of the cupola and the centrifuge inlet.

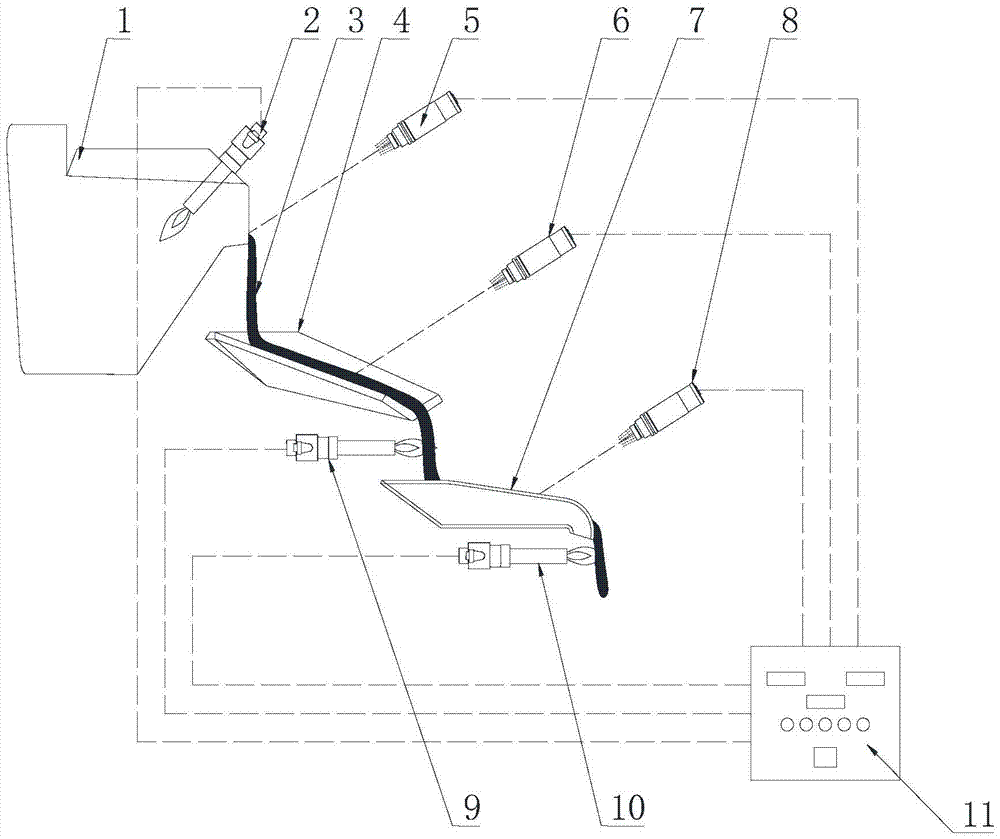

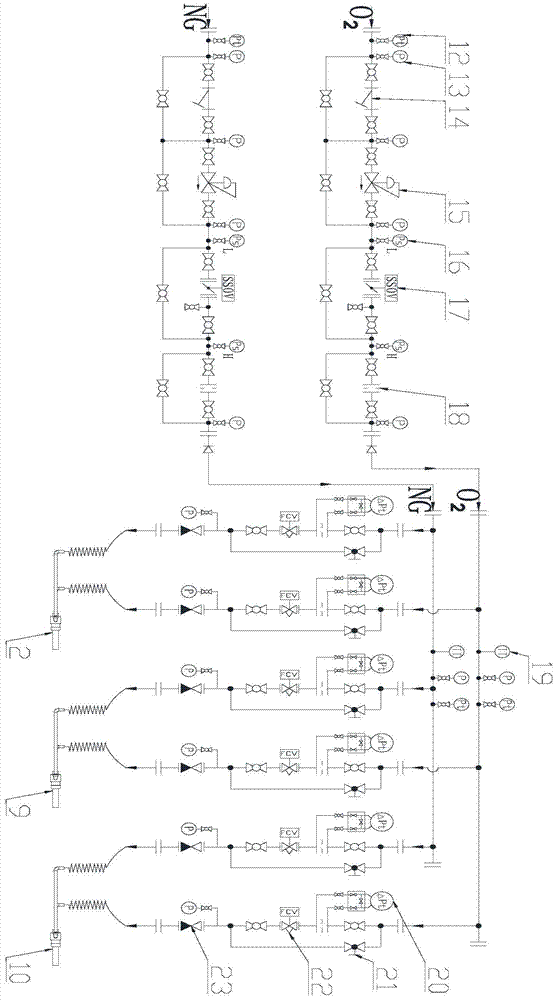

[0041] A pure oxygen combustion system for multi-point precise control of rock wool melt temperature in this embodiment also includes three pure oxygen burners, a pipeline system for providing natural gas and oxygen to the three pure oxygen burners, Online temperature real-time monitoring system and PLC control cabinet 11. Such as figure 2 shown.

[0042] The three pure oxygen burners are No. 1 pure oxygen burner 2, No. 2 pure oxygen burner 9 and No. 3 pure oxygen burner 10; No. 1 pure oxygen burner 2 is set on the top of siphon port 1, and No. Oxygen burner 9 is set at the lower part of No. 1 movable chute 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com