Flash lamp mould set having automatic spring out structure

An automatic pop-up and flash technology, applied in optics, instruments, photography, etc., can solve the problems of high electromagnetic action force, inconvenient use, laborious and other problems, and achieve the effect of protection against external force damage, small action force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

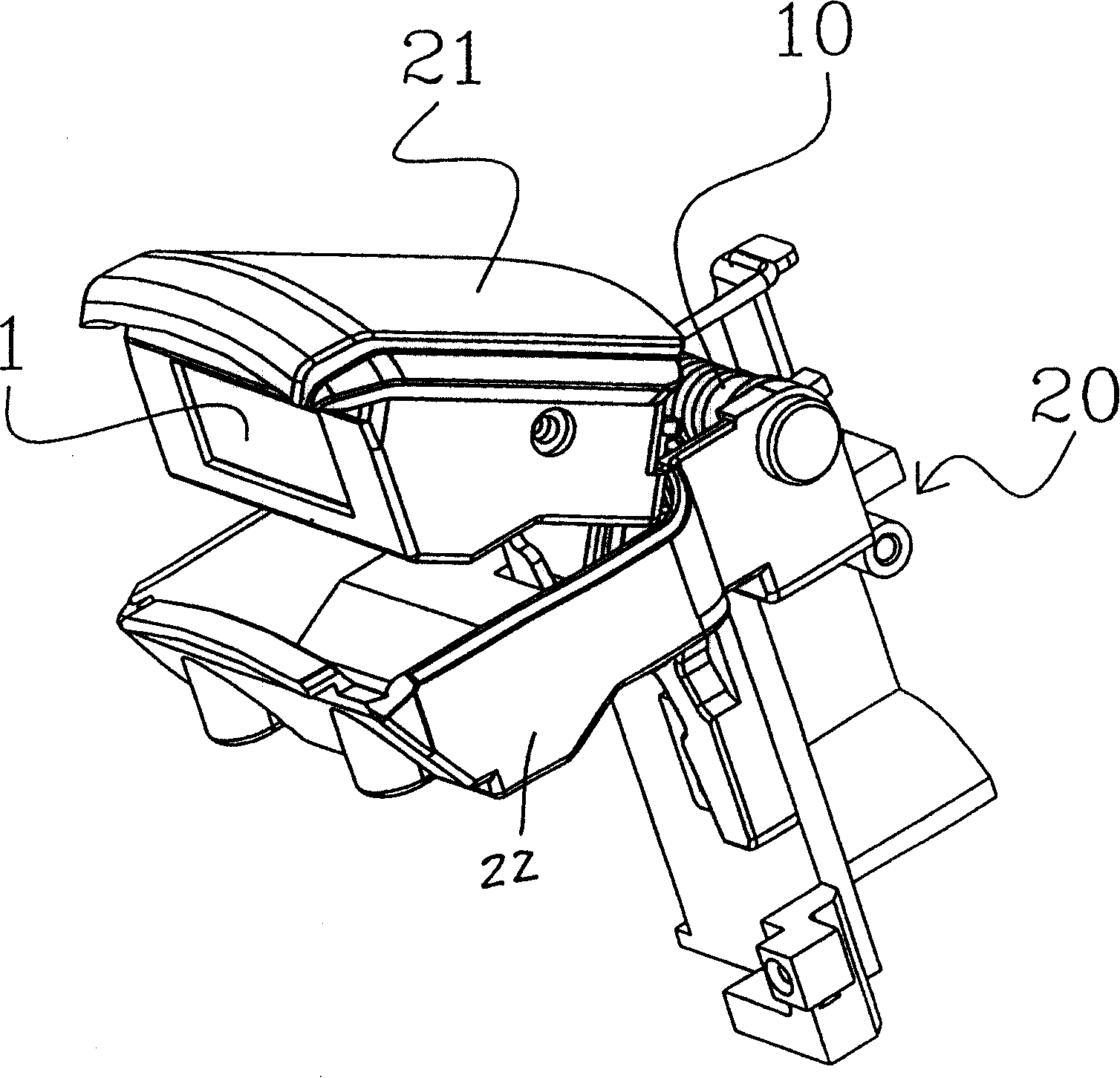

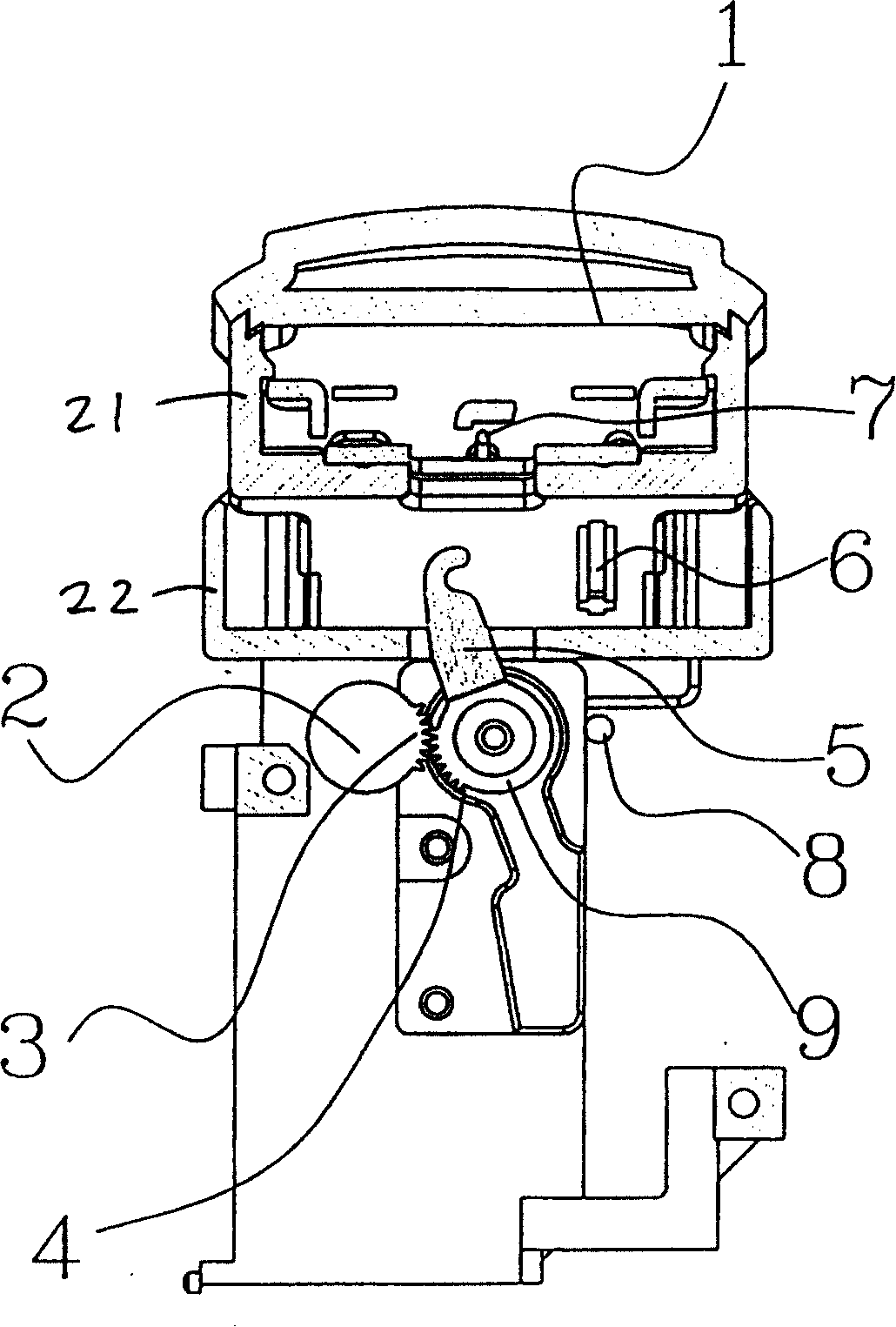

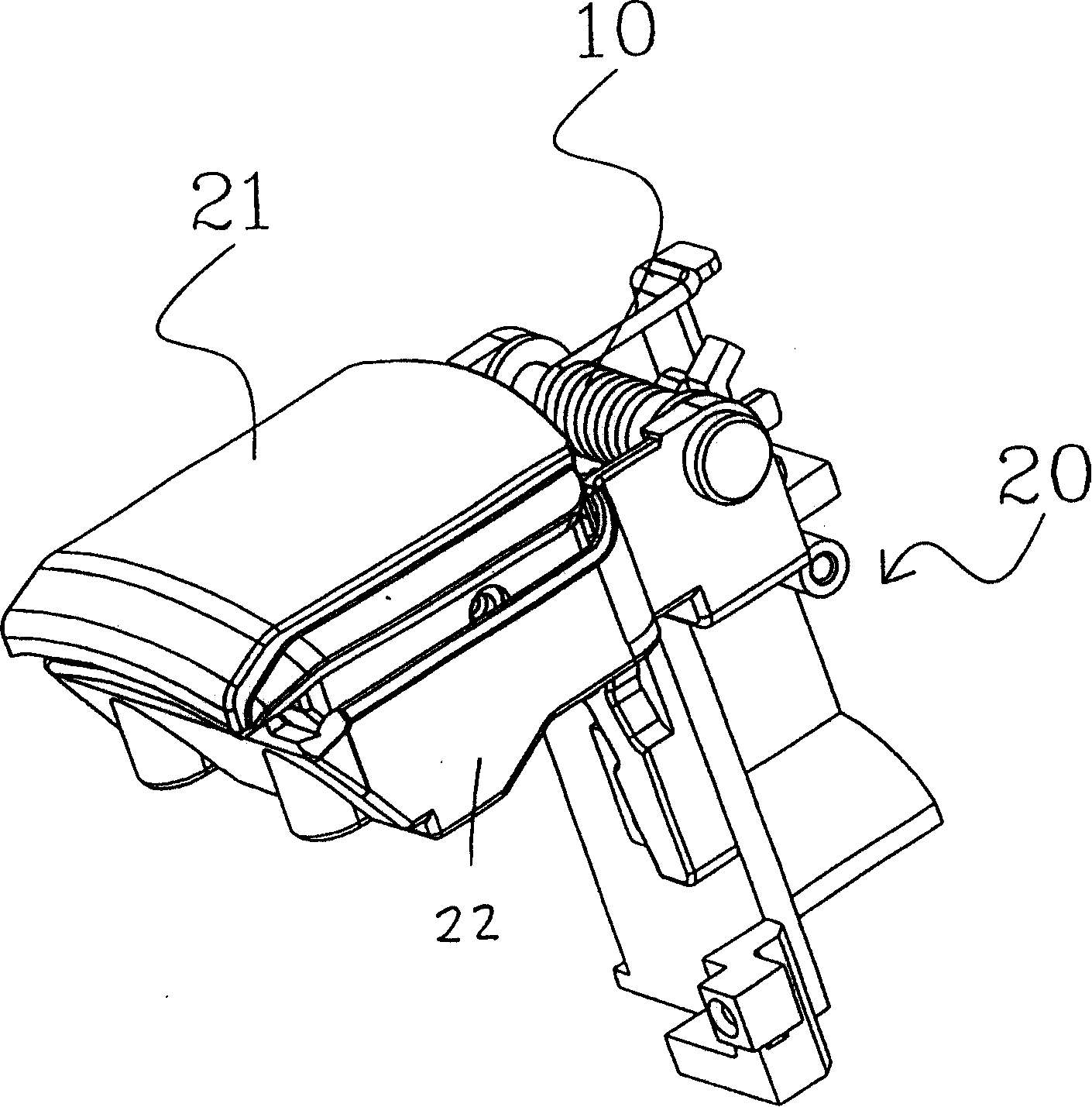

[0020] Such as figure 1 , figure 2 As shown, the flashlight module 20 with an automatic pop-up structure of the present invention includes a flashlight 1, a flashlight housing 21, a flashlight base 22, a spring 10 arranged between the flashlight housing 21 and the flashlight base 22, a rotating structure for the motor 2, and a push tooth 3. Interlocking tooth 4, lock catch 5, push block 6, lock catch 7 arranged on the flashlight housing 21, sensor 8 arranged on the flashlight base 22 and force bar pivoted on the flashlight base 22 9.

[0021] The flashlight 1 is a built-in flashlight housed in a flashlight housing 21 .

[0022] The flashlight housing 21 is pivotally arranged on the flashlight base 22, and can bounce up relative to the flashlight base 22 by the elastic force of the spring 10 when automatically detecting insufficient brightness or bounce up relative to the flashlight base 22 by the elastic force of the spring 10 during manual operation.

[0023] The motor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com