Intramode label film and preparation method thereof

An in-mold label and laser film technology, applied to stamps, instruments, identification devices, etc., can solve the problems of printing layer protection, easy to be worn, and printing layer gloss is not high enough, to achieve ink erosion resistance, protection against external damage, and enhanced The effect of marking performance and decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

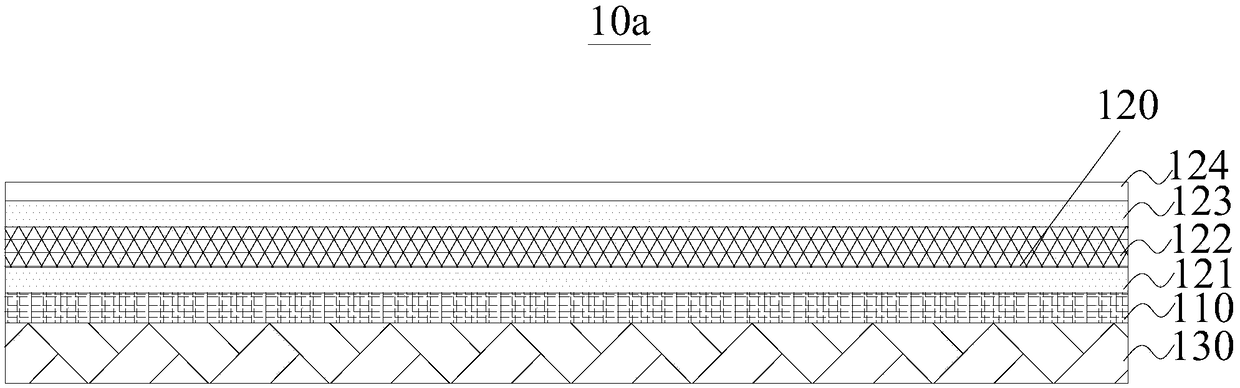

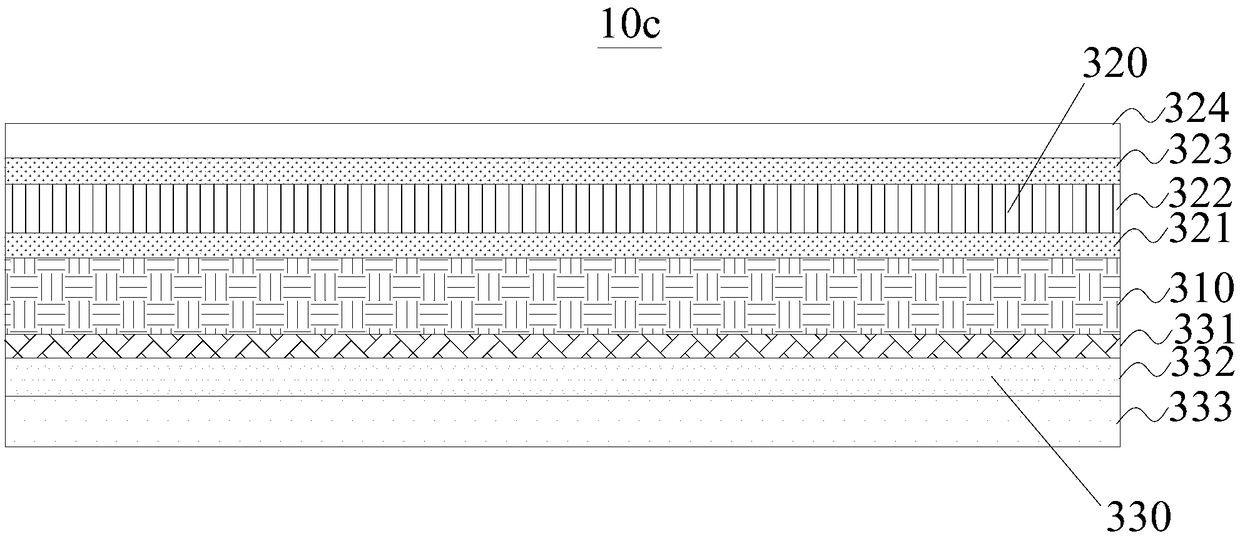

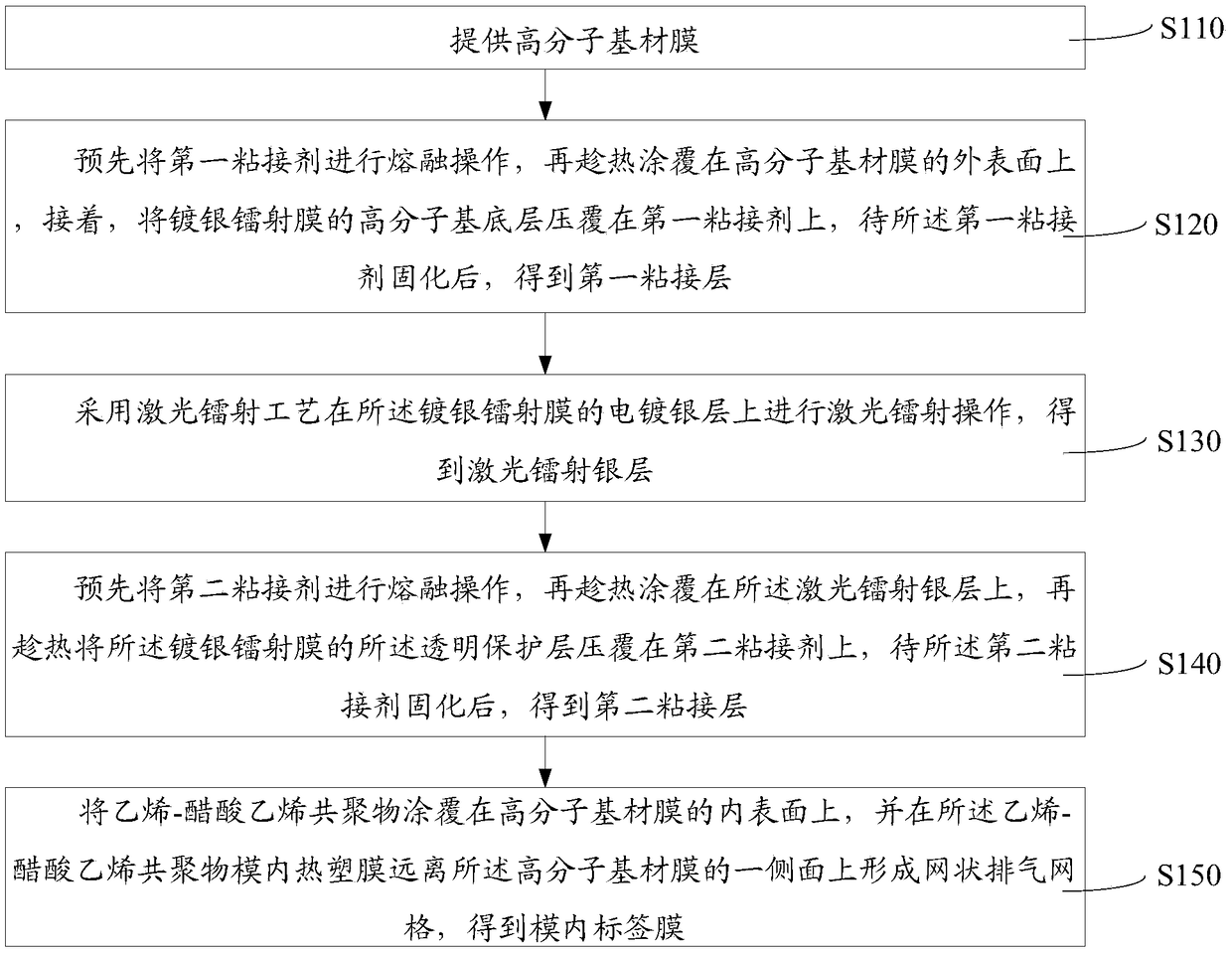

[0058] see image 3 , the preparation method of the in-mold label film of one embodiment, comprises the steps:

[0059] S110, providing a polymer substrate film.

[0060]By providing the polymer substrate film, it can be used as the substrate for the subsequent preparation of the in-mold label film. It can be understood that the polymer substrate film, as the supporting structure of the in-mold label film, needs to have good physical and mechanical properties and chemical properties, and can meet the In the process of plastic blowing, injection molding or thermoforming to integrate the in-mold label film with the plastic container, it has a certain support function to avoid problems such as curling or wrinkling during the molding process, and at the same time can be integrated with other layers The material is firmly bonded to prevent delamination, and it can have a good fusion effect with the plastic container. For example, the polymer base film is a polyolefin film or a pol...

Embodiment 1

[0091] Provide high-density polyethylene resin base film;

[0092] At a temperature of 150°C, add the first adhesive to the reaction kettle, mix and stir for 30 minutes until it is completely melted, and then coat it on the outer surface of the high-density polyethylene resin substrate film while it is hot. A layer of steel pressure roller laminates the polymer substrate of the silver-plated laser film on the first adhesive, and after the first adhesive is cured, a first adhesive layer is obtained, wherein the first adhesive includes Each component of following mass parts: epoxy resin 10g, polyurethane 6g, methyl methacrylate 4g, hydroxyethyl cellulose 3g;

[0093] 3D true color holographic technology is used to perform laser laser operation on silver-coated polyester film to obtain a laser-laser silver layer. The distance between the laser laser machine head and the silver-coated polyester film is 20cm, the laser energy is 200W, and the laser temperature is 150 ℃, laser time...

Embodiment 2

[0098] Provide high-density polypropylene resin substrate;

[0099] At a temperature of 180°C, add the first adhesive to the reaction kettle, mix and stir for 30 minutes until it is completely melted, and then coat it on the outer surface of the high-density polypropylene resin substrate while it is still hot. Then, use a double layer The steel pressure roller laminates the polymer base layer of the silver-plated laser film on the first adhesive, and after the first adhesive is cured, the first adhesive layer is obtained, wherein the first adhesive includes the following: Each component of mass parts: epoxy resin 12g, polyurethane 7g, methyl methacrylate 5g, sodium dodecylsulfonate 4g;

[0100] 3D true color holographic technology is used to perform laser laser operation on silver-coated polyester film to obtain a laser-laser silver layer. Among them, the distance between the laser laser machine head and the silver-coated polyester film is 25cm, the laser energy is 250W, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com