Motor and transmission construction for a hand-held tool

A technology of hand-held tools and transmission devices, which is applied in portable motorized devices, sawing machine devices, manufacturing tools, etc., and can solve problems such as large bending loads on motor shafts and large axial distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

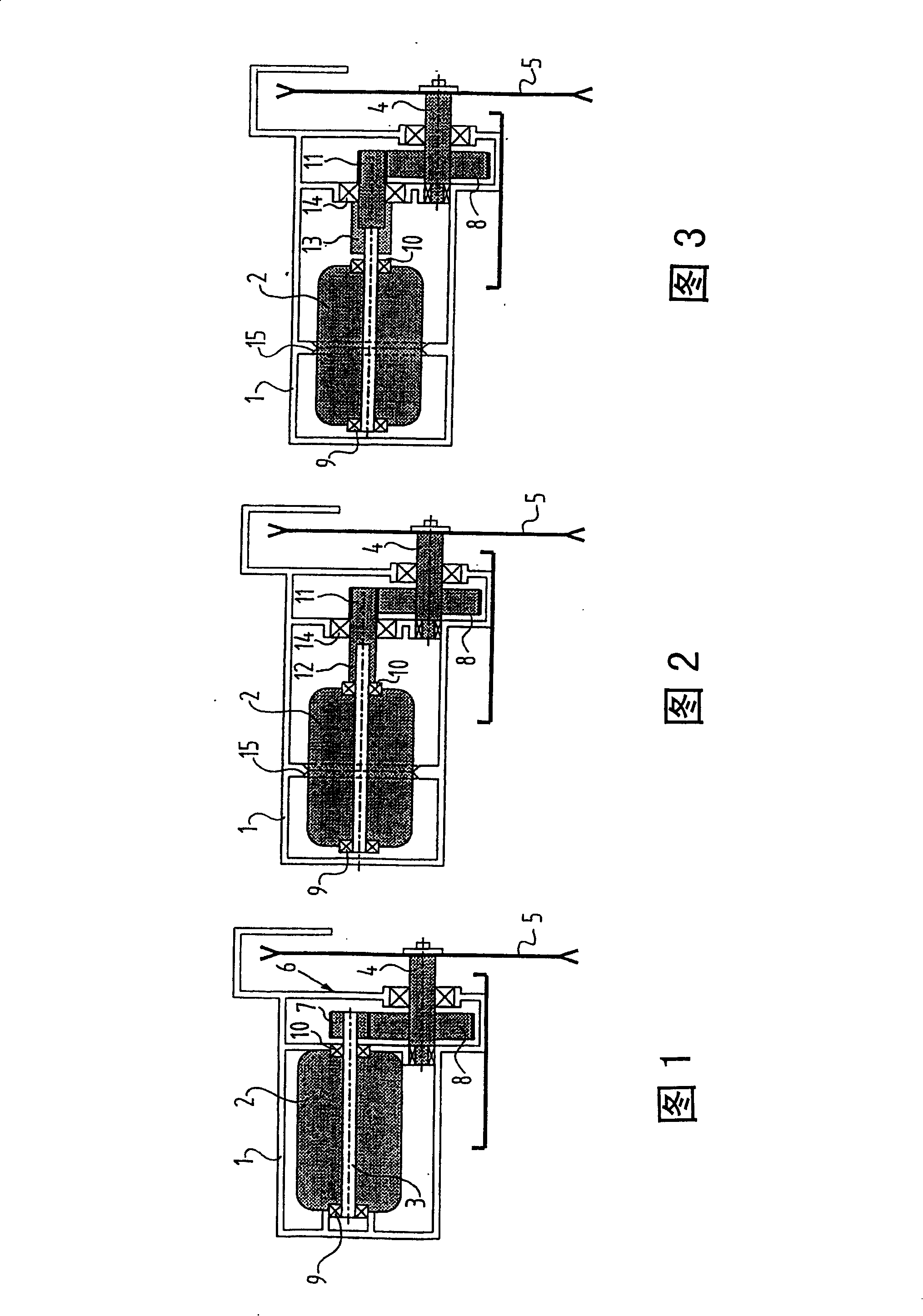

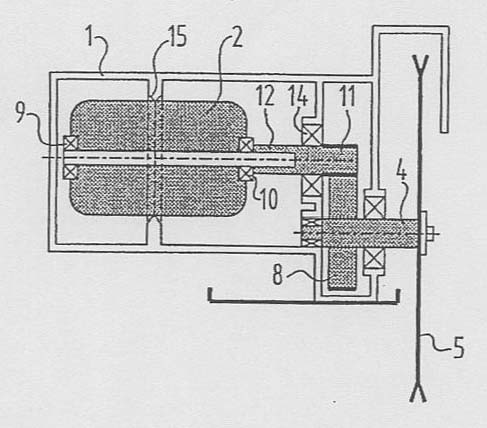

[0016] Figure 1 shows a known circular saw. The circular saw comprises a housing 1, a motor 2 in which a motor shaft 3 is mounted, and a tool shaft 4 rotatably mounted in the housing and on which a circular saw blade 5 is mounted. The tool shaft 4 can be driven by the motor shaft 3 via a transmission 6 . The transmission comprises at least two intermeshing gears 7 , 8 , wherein the first gear 7 is press-fitted on the outer end of the motor shaft 3 . The motor shaft is further fitted near its two outer ends in bearings 9 , 10 , so that the motor 2 with the motor shaft 3 is clamped in the housing via these bearings 9 , 10 .

[0017] 2 and 3 show two embodiments of a circular saw according to the invention. The differences between these circular saws according to the invention and the known circular saw of FIG. 1 will be clarified below. Firstly, the first gear wheel according to the invention is formed by a shaft 11 with a ring gear on the outer surface of its first outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com