People conveyor

A technology for conveyors and passenger transportation, which is applied in transportation and packaging, escalators, etc., and can solve problems such as bridge component falling off and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

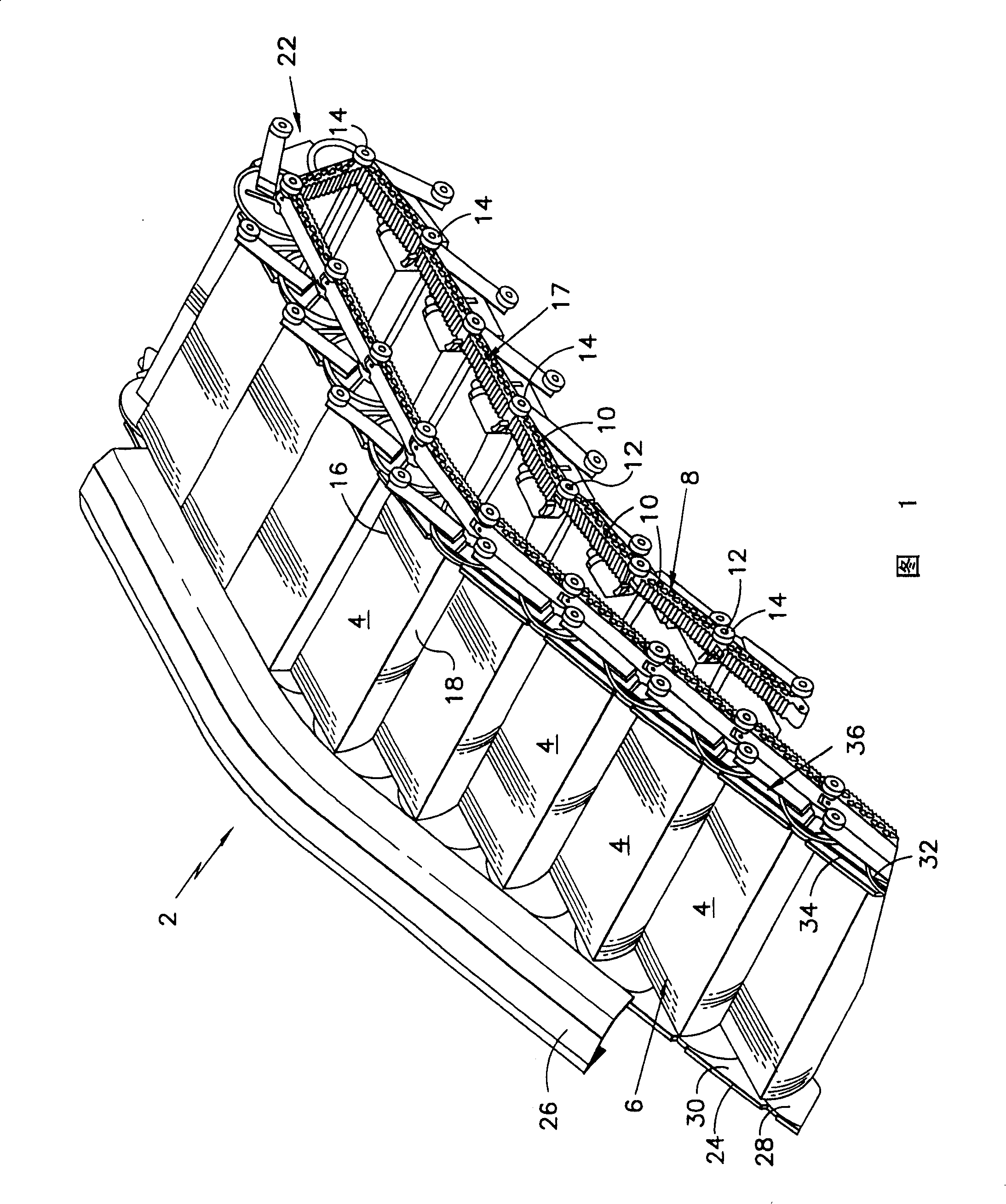

[0021] FIG. 1 shows a passenger conveyor in the form of an escalator 2 , which has an endless stepped belt 6 made up of a plurality of interconnected tread steps 4 . The step ladders 4 are respectively connected with the side conveyor chains 8 . The "sideways" connection to the step ladder 4 includes not only embodiments in which the conveyor belt or the step chain 8 is arranged laterally next to the step step 4 in plan view, but also embodiments in which the step chain 8 In plan view, it is arranged laterally below the tread surface 16 of a tread ladder. The conveyor chain 8 consists of a number of chain links 10 . Chain link 10 and pivot point 12 are connected to each other. Step chain rollers 14 are also arranged at these pivot points 12 , which guide the step chain 8 along a closed circumferential path into a guide (not shown) for the step chain.

[0022] The step chain 2 is driven by a (not shown) linear drive which is designed in the form of a linear drive formed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com