Continuous painted-glass producing process

A technology of painted glass and production methods, which is applied in the direction of glass furnace equipment, glass manufacturing equipment, furnace types, etc., and can solve the problem that the amount of glass coloring material cannot be adjusted and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

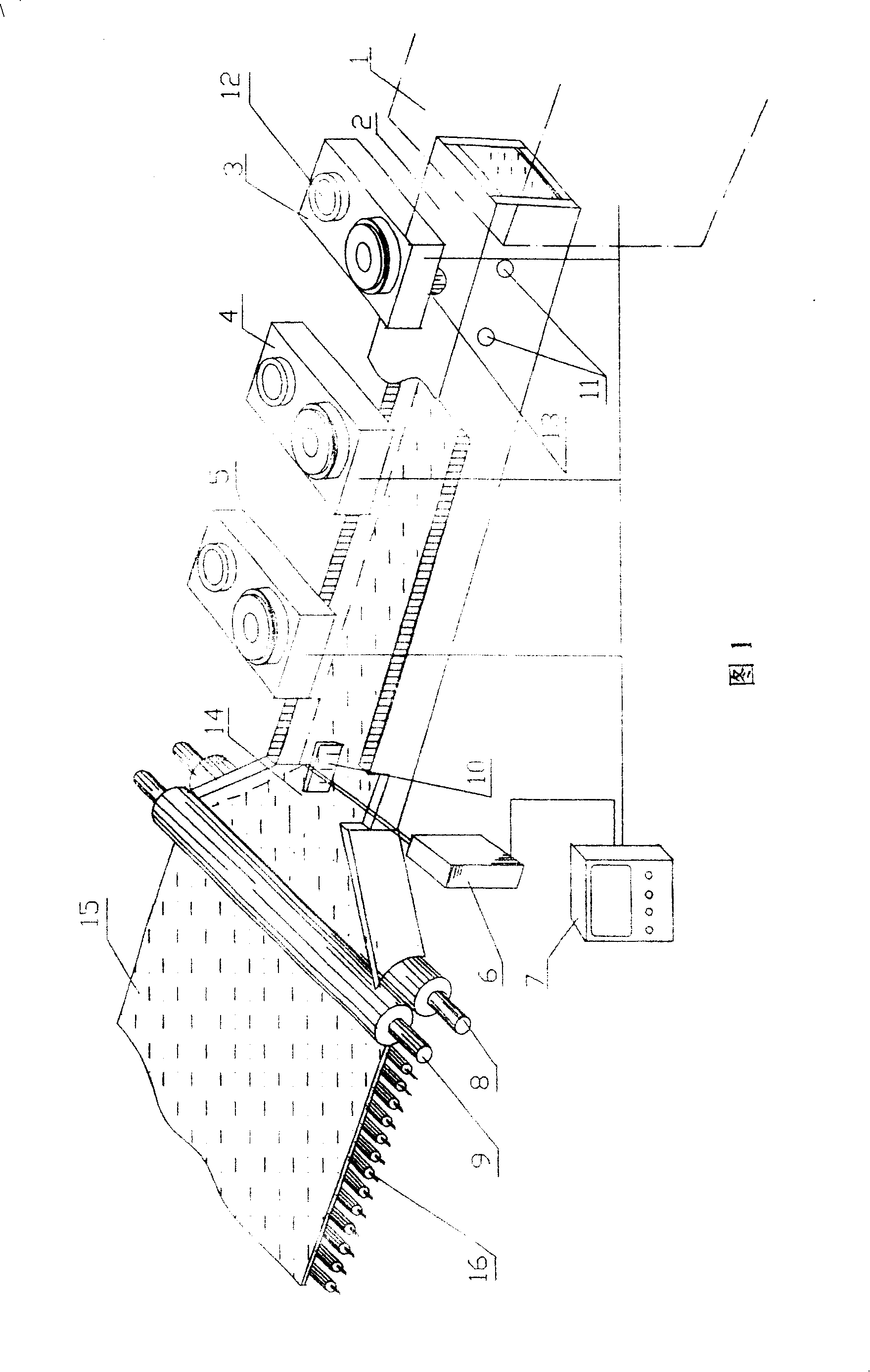

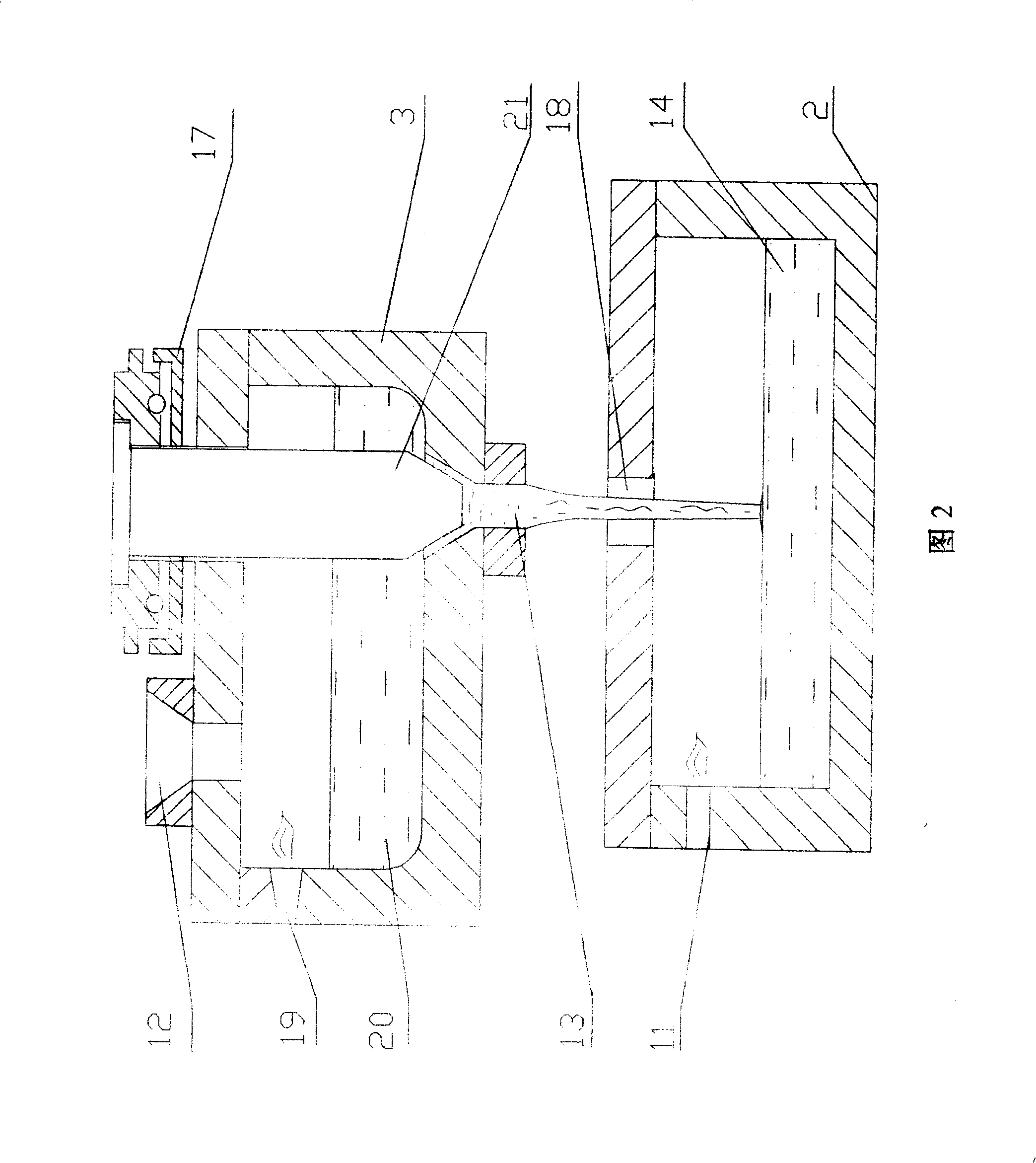

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The present invention specifically produces a kind of blue color, green, porcelain white three kinds of colors alternately 8 * 8 inches, the painted glass face brick that thickness is 6MM. The melted glass base material in the main tank kiln 1 flows into the coloring channel 2 through the working pool. The heating device 11 is installed in the coloring channel 2, and the color material feeders 3, 4, 5 are arranged above the coloring channel. The color material feeder is provided with a color material inlet 12, a molten glass color material outlet 13, and a molten glass color material discharge valve 21. During production, the pigments porcelain white, blue, and green melted by the crucible kiln or pool kiln are imported into the pigment feeder 3, 4, and 5 respectively through the pigment import port 12, and the color material feeder is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap