Steam pipeline laying method for thermoelectric plant

A technology for a steam pipeline and a laying method, which is applied in the direction of pipeline laying and maintenance, protection of pipelines and pipeline supports through thermal insulation, etc. Dislocation of pipes and steel shells, etc., to achieve the effect of strengthening thermal insulation, waterproofing and protection, simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

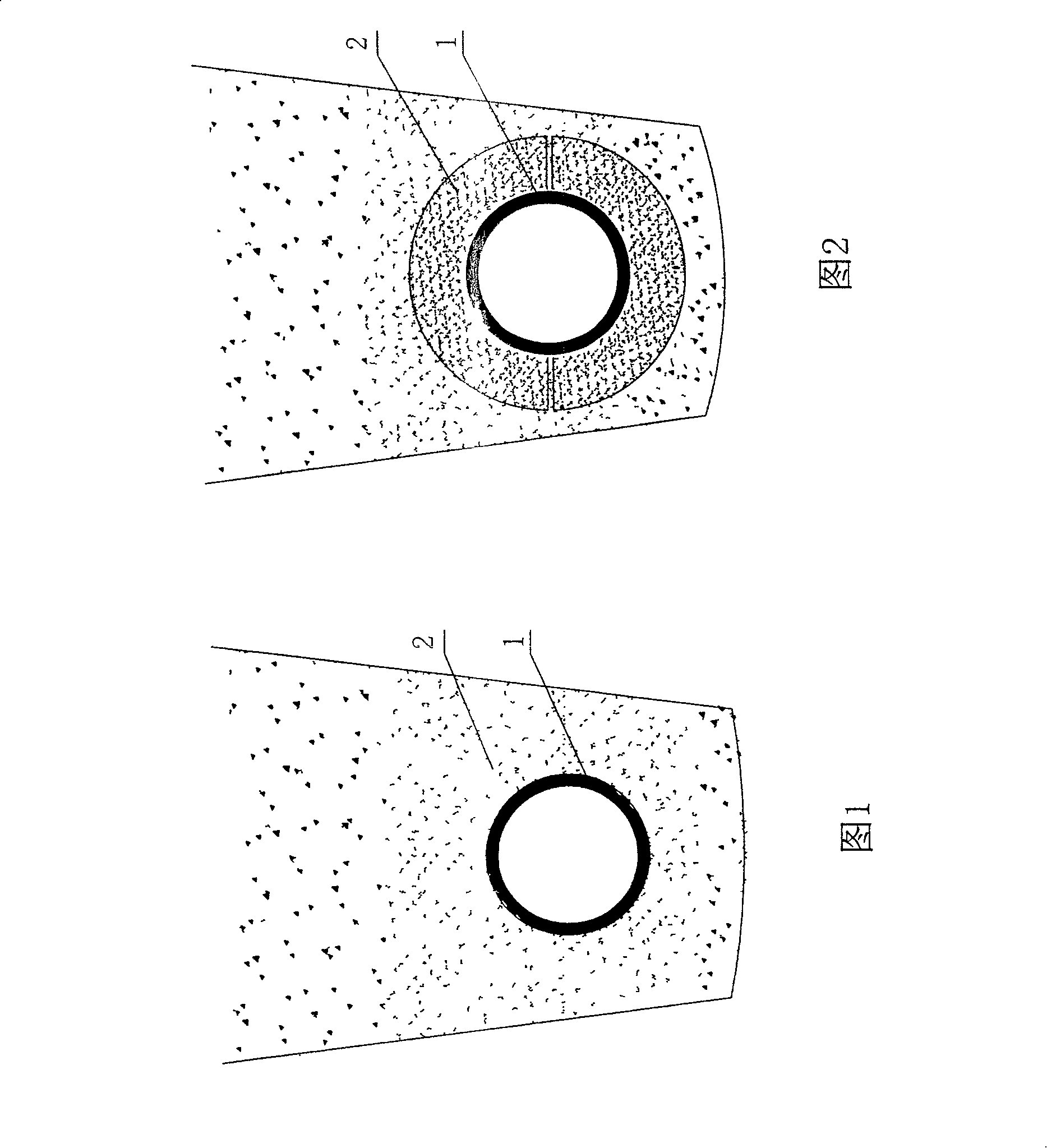

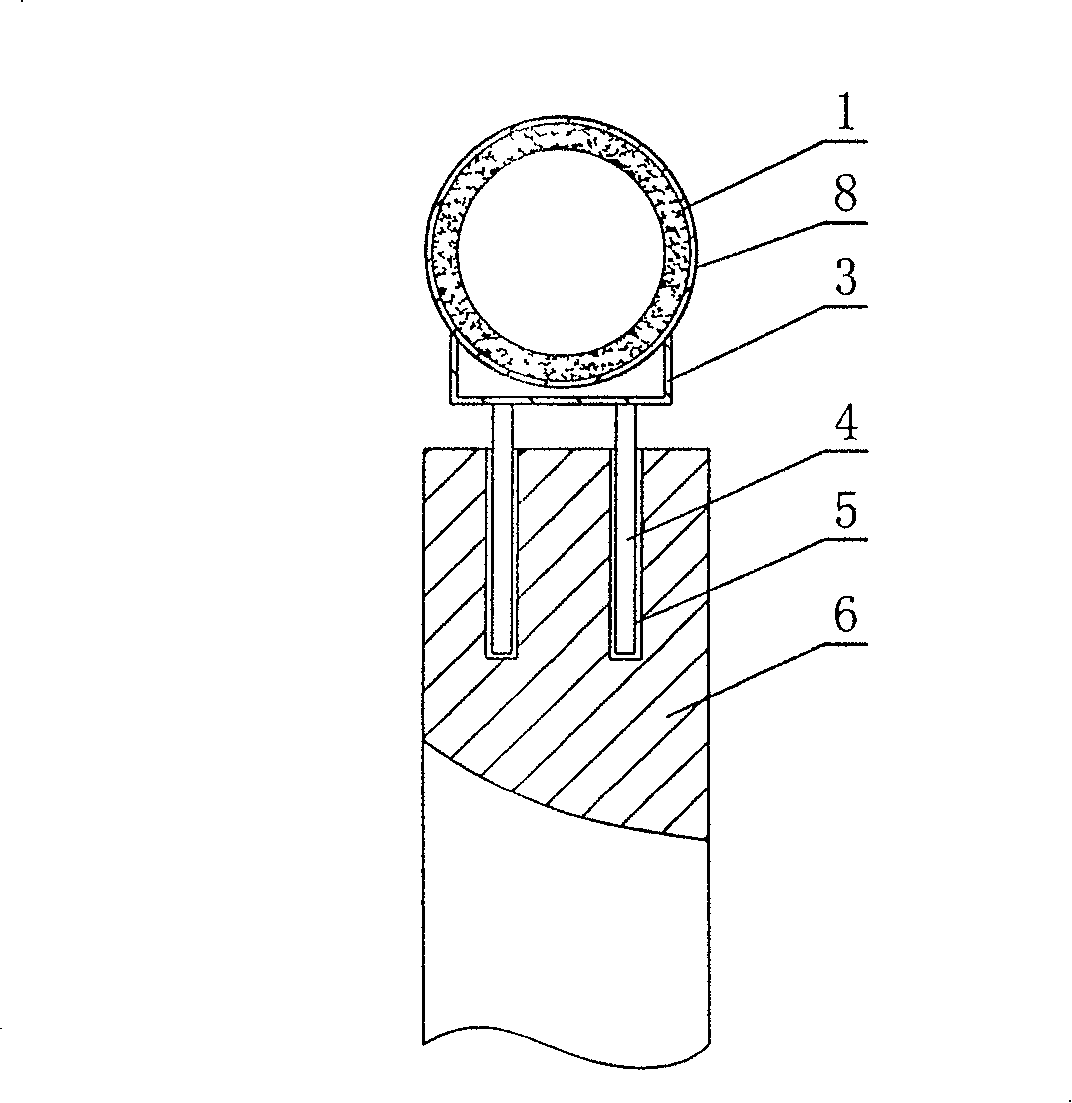

[0046] As shown in accompanying drawing 1, in thermal power plant steam pipeline laying method of the present invention, the laying of thermal insulation waterproof underground pipeline comprises the following steps:

[0047] a. After excavating the pipeline ditch, fill the bottom of the ditch with sand as the foundation, compact and level it;

[0048] b. Fill with 10-30cm thick fly ash, lay the steam pipe on the fly ash, and then cover the steam pipe with 10-30cm thick fly ash;

[0049] c. Fill the top of the fly ash with gravel soil.

[0050] Once the fly ash encounters water or moisture, it will solidify immediately around the steam pipe 1 to form a solid fly ash waterproof insulation pipe shell 2.

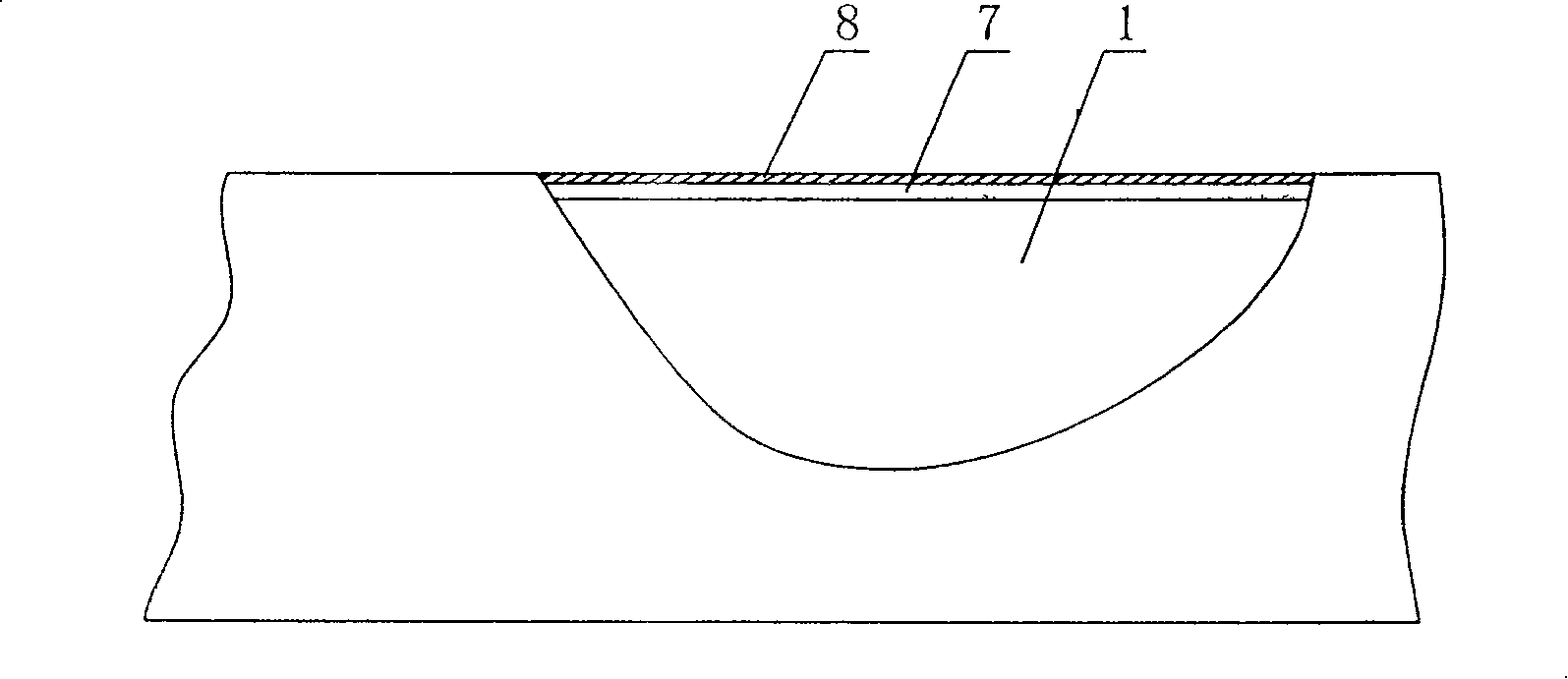

[0051] As shown in Figure 2, in the laying process of thermal insulation and waterproof underground pipelines, the fly ash can also be processed into a semicircular fly ash waterproof and thermal insulation shell 2 by using a mold, and then half of the waterproof and thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com